In modern livestock operations, efficient material handling systems are vital. They must endure rigorous daily use while maintaining top performance. This detailed guide explores key components, maintenance approaches, and technological advancements. These make conveyor belts essential in today’s farms. From choosing robust materials to adopting AI-driven monitoring, these strategies prevent costly downtime.

What Makes Livestock Conveyor Systems Crucial?

Components and Functions of Livestock Conveyor Systems

Livestock conveyor belts are vital for modern farming. They boost productivity and streamline material handling. These systems include belts, pulleys, rollers, and motors. The belt acts as the primary transport surface. It moves feed, bedding, or manure efficiently. Pulleys and rollers ensure proper tension and alignment. Motors supply power to drive the system.

The main role of these belts is to enable smooth material movement. They transport feed to animals or remove waste from barns. This reduces manual labor and enhances farm efficiency.

Common Issues in Livestock Conveyor Operations

Despite their benefits, conveyor belts face challenges. Harsh conditions like moisture or heat cause wear. Incorrect tensioning leads to misalignment or slippage. This lowers efficiency. Overloading can damage the belt or cause system breakdowns.

How Can You Boost Durability with Proper Care?

Regular Inspections and Cleaning Practices

Frequent checks are essential to spot wear early. Look for cracks, frayed edges, or odd noises during operation. Addressing issues quickly prevents expensive repairs.

Regular cleaning stops debris buildup. This maintains performance and hygiene. Use gentle tools and suitable cleaning agents. These avoid damaging the belt material.

Lubrication and Alignment for Smooth Operation

Lubrication reduces friction between parts. It ensures smooth function and extends component life. Misaligned belts increase wear. Regular alignment checks are critical.

Importance of Tension Control for Optimal Function

Proper belt tension prevents slippage or motor strain. Adjust tension regularly. Follow manufacturer guidelines for consistent performance.

Which Materials Suit Livestock Conveyor Systems Best?

Choosing the right materials is key for performance in tough environments.

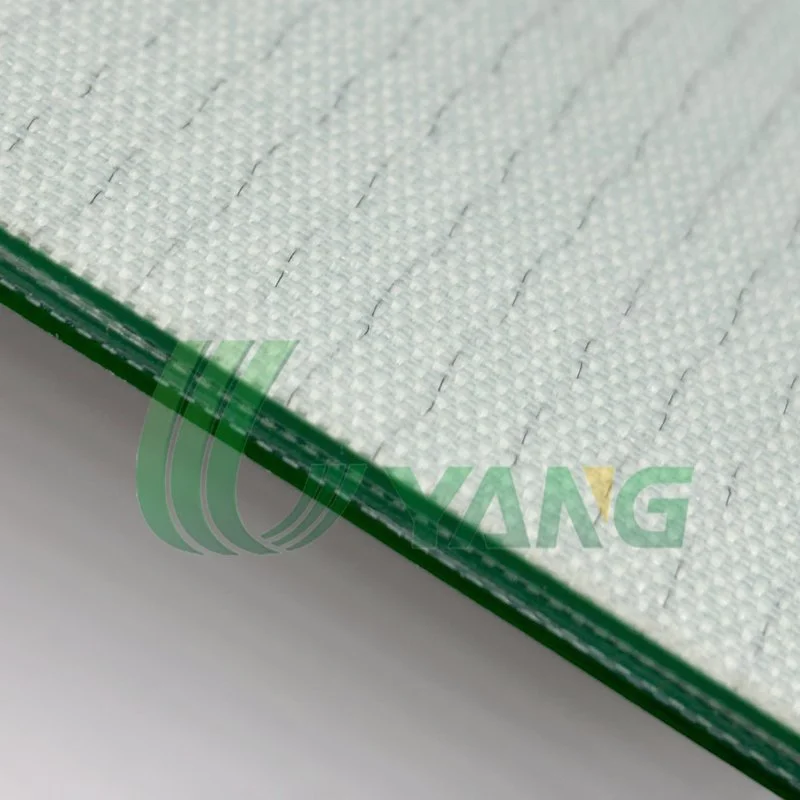

Material Features for Enhanced Durability

Heat-Resistant Materials for High-Temperature Settings

In high-heat environments, like processing plants, heat-tolerant materials are ideal. Rubber or specialized polymers withstand thermal stress effectively.

Anti-Corrosive Coatings for Longevity

Belts exposed to moisture benefit from anti-corrosive coatings. These prevent rust and degradation. They ensure durability in harsh conditions.

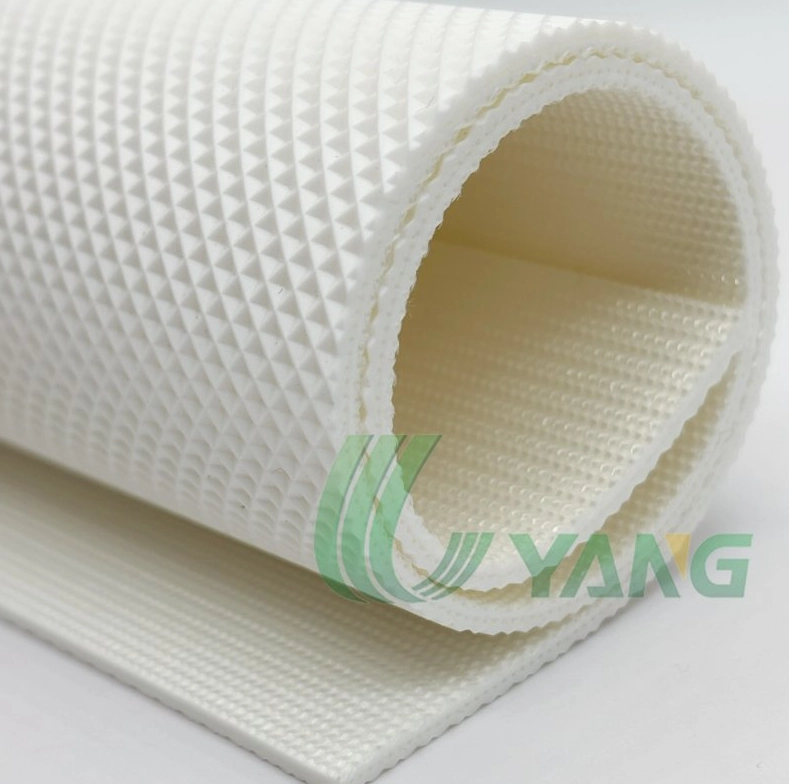

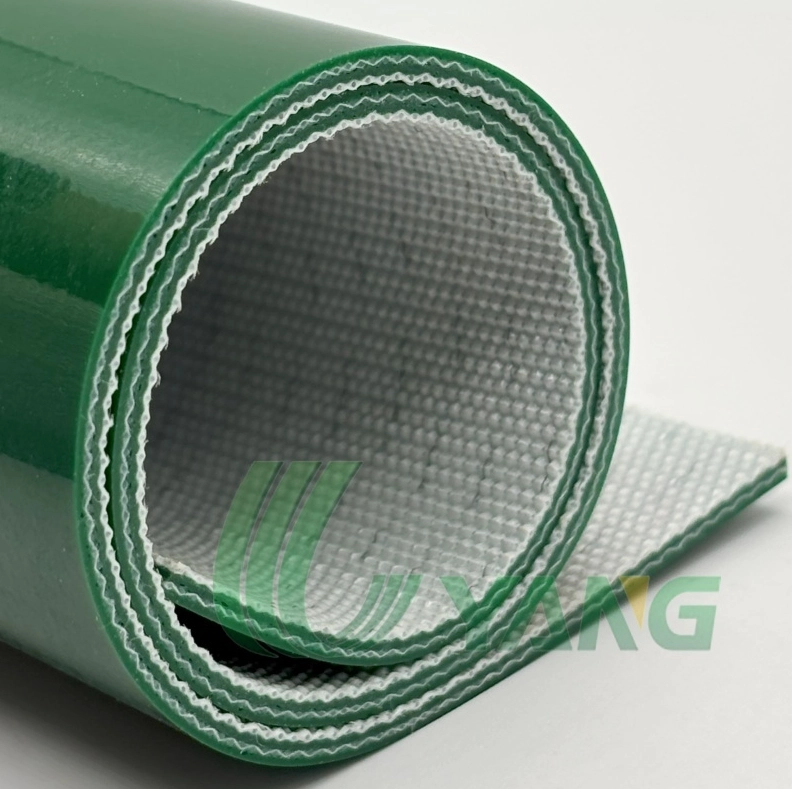

Recommendations from Uyang Belting’s Product Range

For reliable solutions, consider Uyang Belting’s conveyor systems. With over 20 years of expertise, they offer durable belts designed for agricultural use.

What Operational Changes Improve Efficiency?

Effective load management is critical for conveyor efficiency and longevity.

Optimizing Load Distribution on Conveyor Systems

Preventing Overloading to Avoid Damage

Overloading stresses the belt and motor. Always follow the manufacturer’s load capacity guidelines.

Efficient Loading Methods

Spread loads evenly across the belt. This prevents imbalances, misalignment, or uneven wear.

Speed Control and Its Effect on Performance

Adjust conveyor speed based on material type. This ensures efficient handling. Slower speeds suit delicate items like feed pellets. Faster speeds work for bulkier materials.

Advanced Technologies for Livestock Conveyor Systems

Automation is transforming conveyor systems. Smart monitoring and AI-driven maintenance set new standards for efficiency and reliability in farming.

How Does Automation Improve Belt Monitoring?

Smart Sensors for Real-Time Data

Automation has revolutionized conveyor systems. Smart sensors collect real-time data on belt conditions. They monitor tension, temperature, and wear. This helps detect issues early. It prevents costly repairs or downtime.

Predictive Maintenance with AI Tools

AI analyzes sensor data to spot patterns. It predicts component failures. This allows timely maintenance. It reduces unexpected outages and extends belt life. AI optimizes performance and cuts costs.

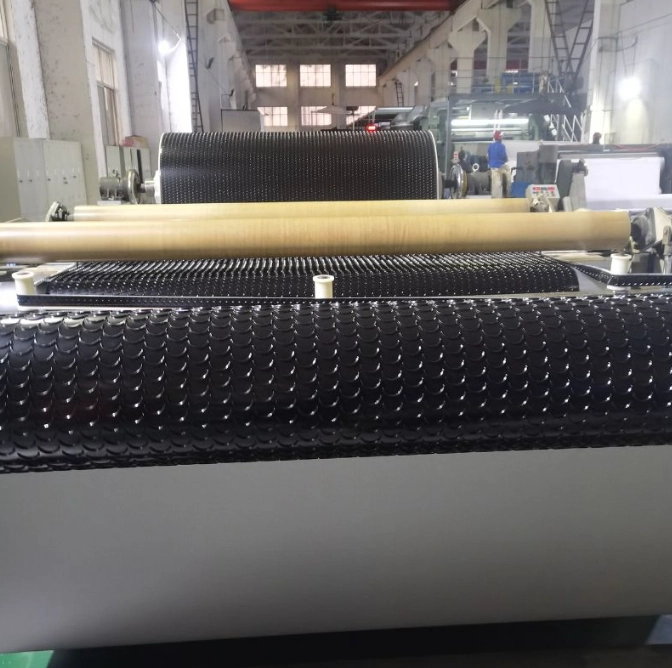

Technological Innovations from Uyang Belting

Uyang Belting leads in innovation. Their 80,000-square-meter facility has 15 automated production lines. This ensures cutting-edge solutions for livestock operations.

Selecting High-Quality Products for Reliable Performance

How to Assess Belt Specifications for Specific Needs?

Choose belts based on operational demands. Consider material type, load capacity, and environmental conditions. Rubber belts suit heavy-duty tasks due to their strength and abrasion resistance. PVC belts work for lighter tasks like feed transport.

Benefits of Tailored Solutions

Customized belts improve efficiency and durability. They meet specific operational needs, whether for feed or waste. Tailored designs from trusted manufacturers reduce wear and enhance performance.

Training and Workforce Role in Maintenance

Why Train Operators on Proper Techniques?

Training is vital for maximizing belt efficiency and lifespan. Operators should learn correct loading and tensioning methods. This prevents issues like overloading or misalignment.

How to Set Up Routine Maintenance Schedules?

Regular maintenance ensures long-term reliability. Conduct frequent inspections to catch wear early. Follow cleaning protocols to avoid debris buildup. Maintain lubrication schedules to reduce friction.

FAQs:

Q1: How does AI help maintain livestock conveyor systems?

A: AI analyzes sensor data to predict failures. This enables timely maintenance and reduces downtime.

Q2: How often should maintenance be performed?

A: Schedules vary. Monthly inspections and regular cleaning are recommended based on usage.

Q3: What materials suit heavy-duty livestock operations?

A: Rubber belts are ideal. They offer strength and resist abrasion in tough environments.