PVC conveyor belts appear in many modern production lines. They show up in areas like food processing and packaging, as well as logistics and light manufacturing. These belts quietly move materials along and ensure workflows stay on schedule. Yet, picking the correct PVC conveyor belt goes beyond just the belt. The maker behind it matters far more than most buyers realize at first.

The global market is full of options, and quality varies a lot between suppliers. Thus, locating a maker who grasps actual application demands is essential. Firms such as UYANG BELTING, a skilled PVC conveyor belt manufacturer, shine by blending reliable production, design focused on uses, and a wide array of products that suit various sectors.

This piece explains the main points to watch when selecting a PVC conveyor belt manufacturer. It also shows how a smart pick can aid ongoing performance, rather than mere short-term savings on costs.

What Factors Should You Consider When Choosing a PVC Conveyor Belt Manufacturer?

Prior to checking belt types or costs, take a moment to view the manufacturer overall. A solid supplier delivers more than items listed in a catalog. Factors like production skills, hands-on knowledge, and service approach all shape how effectively a belt works after setup.

By grasping these main elements, buyers can dodge typical problems. Such issues include quick belt damage, alignment troubles, or weak fit with current conveyor setups.

Manufacturing Quality Standards

Steady quality begins right in the factory. A trustworthy PVC conveyor belt manufacturer upholds even production methods, managed material supplies, and thorough checks at each step. This matters greatly in fields like food processing or packaging, where things like surface quality, cleanliness, and toughness count daily.

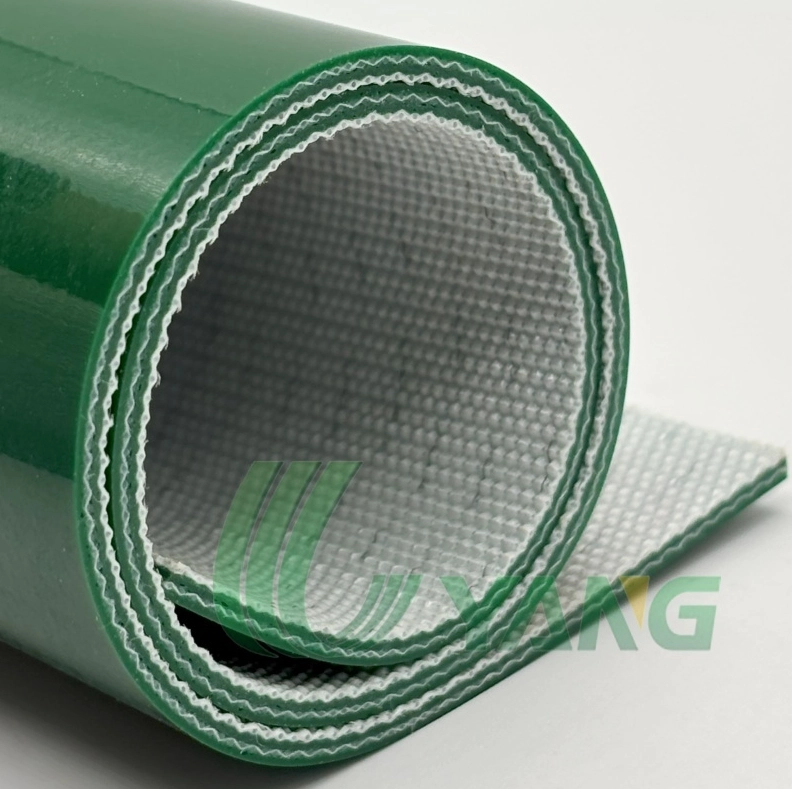

UYANG BELTING puts effort into PVC belt production. It pays close attention to even coating, strong fabric links, and uniform surfaces. These aspects cut down on sudden breakdowns. As a result, they allow belts to run reliably under regular loads, rubbing, and wash routines.

Product Range and Specialization

A maker with a narrow product selection usually makes customers tweak their operations to fit the belt. On the other hand, a varied and focused product lineup lets users pair belt features better with their specific tasks.

UYANG BELTING provides several PVC conveyor belt surface styles, shades, and builds. Options range from sleek shiny belts to rough and grooved patterns. This variety aids packing setups, sloped conveyors, and item sorting jobs. It does so without forcing extra trade-offs.

Customer Support and After-Sales Service

A well-made belt might still require help during fitting or tuning. Quick technical aid can stop halts in work and cut down on guesswork in the production area.

A capable manufacturer needs to ensure open talks, tips on uses, and prompt replies to queries. Such service proves extra useful for those handling several conveyor lines or tailored designs.

Why Is Material and Surface Type Critical in PVC Conveyor Belts?

PVC conveyor belts might seem alike on the surface, but their material build and surface style alter how they act in daily tasks. Things like hold, cleaning needs, and item steadiness all depend on the surface choice.

Selecting the proper surface often means the line between easy daily runs and ongoing belt fixes.

Blue Glossy PVC Conveyor Belt Features and Advantages

The Blue Glossy PVC Conveyor Belt from UYANG BELTING suits spots where sanitation and even item flow top the list. Its shiny layer lowers drag while letting goods slide smoothly over the belt.

This belt type fits well in packing, sorting, and basic manufacturing paths. Plus, the even surface speeds up cleaning tasks. Therefore, it cuts pauses in places with regular rinses. The blue shade aids sight checks and suits regulated work zones.

Crescent Top White PVC Conveyor Belt Benefits

When tasks need added hold without harming goods, the Crescent Top White PVC Conveyor Belt gives a useful fix. Its curved surface design boosts pull, particularly on sloped paths or with frequent starts and stops.

This belt sees wide use in food handling and processing lines. There, white belts aid cleanliness rules, and the rough texture stops slips. The mix of hold and soft touch makes it right for wrapped foods, boxes, and light loads.

Longitudinal Rib PVC Conveyor Belt Applications

The Longitudinal Rib PVC Conveyor Belt aims for firmness and path guidance. Its grooved setup steers items straight along the belt and cuts side drifts, especially on angled or slim conveyors.

This belt performs nicely in shipping, goods shifting, and cases where straight lines count. By holding items firm, it lowers blockages and boosts conveyor output overall. It achieves this without extra machine parts.

How Can Customization Improve Conveyor Belt Performance?

Basic belts meet lots of demands, but tailoring lets a conveyor match its cargo, pace, and setting more closely. Minor changes in belt size, surface, or shade can bring clear benefits to routine work.

A maker who backs tailoring can adjust items to fit true factory setups. Thus, it avoids the need for forced fixes.

Customized Widths and Thicknesses for Specific Workflows

Varied conveyor bases and weights call for different belt sizes. A belt too slim might damage sooner, whereas one too large wastes power and money.

UYANG BELTING handles tailored widths and depths. This matches belt toughness to real weight needs. Such a method aids extended use and even system runs, particularly in nonstop settings.

Surface Texture Tailored to Product Type

Surface roughness shapes how goods act on the belt. Shiny even layers cut pull, while rough ones raise hold and direction.

Through choices like shiny, curved top, and straight grooved surfaces, UYANG BELTING lets users pick patterns that fit item form, mass, and motion styles. This cuts harm to products and shortens tweak time amid process shifts.

Color Coding and Material Grades for Industry Needs

Shade serves more than looks. It aids eye checks, grouping, and rule-following in some fields. Blue and white PVC belts often appear in food and packing lines for simple views.

Varied PVC material levels also shape resistance to oils, dampness, and wash chemicals. Picking the best mix backs both safety and lasting strength.

What Role Does Price and Value Play in Manufacturer Selection?

Cost always enters the discussion, but zeroing in on the cheapest bid frequently brings bigger expenses later. A belt that breaks down fast or sparks repeated stops can run far pricier than its starting tag.

Cost Comparison of Standard vs Customized PVC Belts

Basic belts tend to cost less at the outset. However, they might not suit exact tasks fully. Tailored belts carry higher initial prices, yet they often trim upkeep, alignment woes, and early swaps.

In numerous setups, the scale tips to tailored picks. These fit tighter and endure longer in true conditions.

Long-Term Savings from Durable UYANG BELTING Solutions

Toughness figures large in full ownership costs. PVC conveyor belts from UYANG BELTING handle ongoing runs, washes, and weight strain. They do this without fast surface harm or layer splits.

This strength lowers swap rates and surprise halts. In turn, it outweighs minor cost gaps in the long run.

Warranty and Value-Added Services from Reliable Manufacturers

A straightforward warranty and useful post-purchase aid build assurance in buys. They show the maker backs its goods’ quality and output.

Teaming with a provider that gives tech input and lasting help lets buyers skip hard-to-spot risks from the start.

What After-Sales Services Should You Expect From a PVC Conveyor Belt Supplier?

Post-sales aid gets skipped often until trouble hits. In truth, it forms a core part of the maker’s worth. Firm backing can speed up fixes and keep output steady.

Technical Guidance and Installation Support

Right setup impacts alignment, pull, and belt duration. Straightforward tips from the provider aid fitters in dodging usual errors. This saves hours in prep.

Makers with real-use know-how can suggest ways to boost conveyor work without big shifts.

Maintenance Tips and Replacement Policies

Regular care stretches belt life, provided it’s done right. Useful care advice helps avoid surface harm and early breakdown.

Plain swap rules and wait times also let buyers schedule ahead. Thus, they cut output dangers.

Responsive Customer Service for Troubleshooting

Swift contact counts when work stalls. A quick provider spots problems fast and gives solid fixes over vague replies. This kind of aid fosters ongoing faith and aids steady partnerships.

FAQ

Q1: How do PVC conveyor belts differ from rubber conveyor belts?

A: PVC conveyor belts weigh less, clean simpler, and fit better for food processing, packaging, and light manufacturing. Rubber belts typically serve heavy tasks like mining or bulk handling.

Q2: Which PVC conveyor belt surface is best for inclined conveyors?

A: Rough surfaces like crescent top or longitudinal rib PVC conveyor belts offer stronger hold and item steadiness on sloped conveyors.

Q3: Can PVC conveyor belts be customized for specific industries?

A: Yes. Makers like UYANG BELTING provide tailoring in width, thickness, surface roughness, shade, and material level to suit varied sector demands.