In the bustling world of logistics, conveyor belts are the unsung heroes, tirelessly shuttling goods through warehouses, airports, and factories. PVK belts shine brilliantly in rugged, high-speed tasks like airport baggage handling or automated warehouse systems. They boast unmatched sturdiness, hefty load-bearing prowess, and resilience against scorching heat. Meanwhile, PVC belts dazzle in lighter, budget-friendly roles, such as food processing or packaging lines, where their nimble flexibility, resistance to harsh chemicals, and easy upkeep steal the show. Choosing between them boils down to your operation’s heartbeat—PVK belts for relentless endurance, PVC belts for cost-savvy, frictionless efficiency. Manufacturers like Uyang Belting craft bespoke solutions, ensuring every logistics need finds its perfect match.

Overview of PVK Belts and PVC Belts

What Are PVK Belts and Their Characteristics?

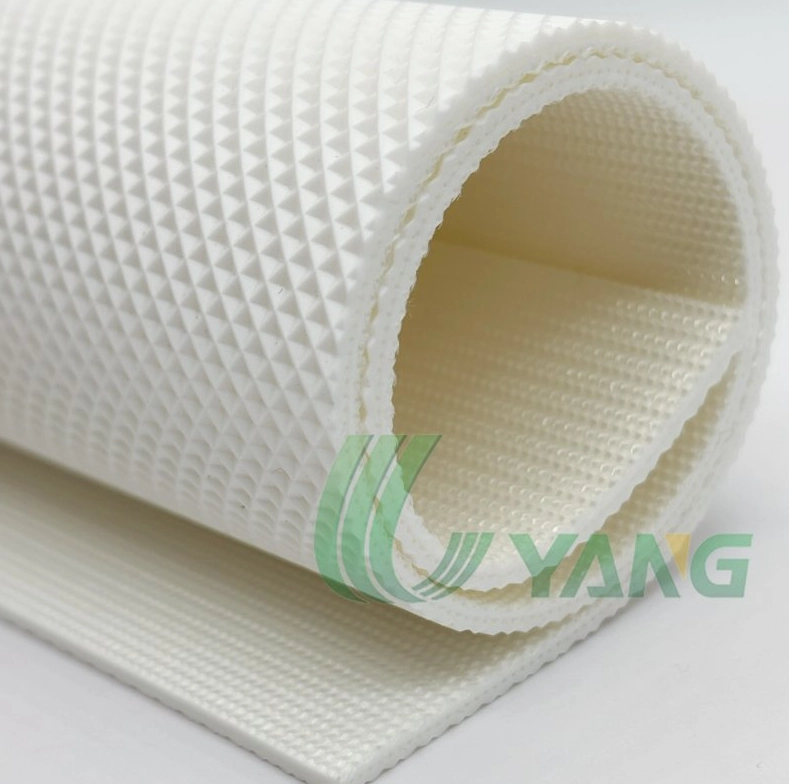

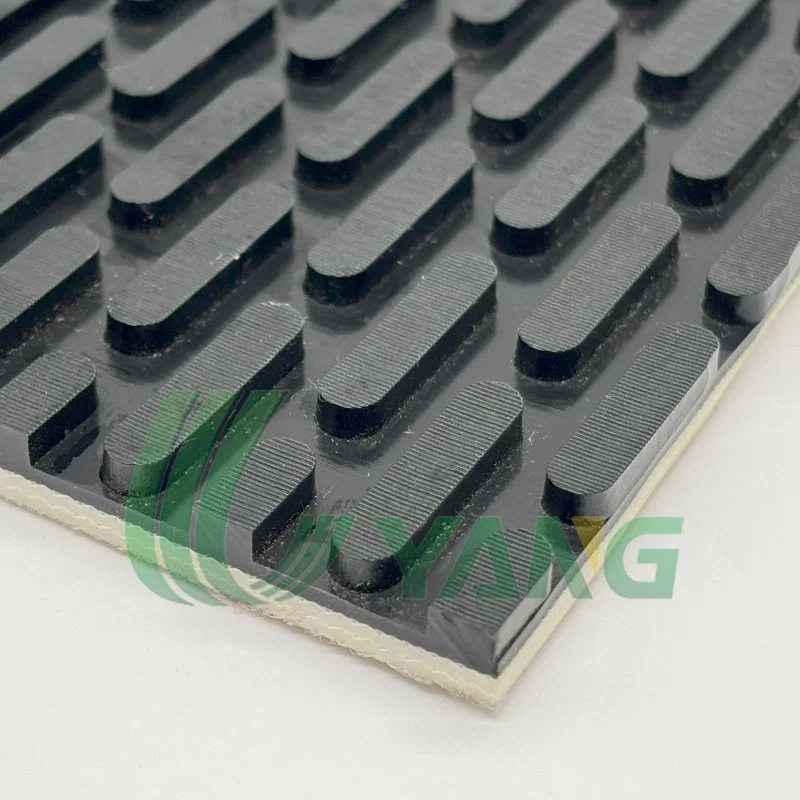

PVK belts are the stalwart champions of conveyor systems, purpose-built for logistics and material handling. Crafted from a sturdy blend of polyester fabric and a polyvinyl alcohol coating, they radiate exceptional toughness. These belts laugh in the face of wear and tear. Their ironclad construction makes them the go-to for heavy-duty missions, like shepherding luggage through chaotic airport terminals or powering relentless warehouse automation. With Herculean tensile strength, PVK belts carry hefty loads without flinching or fraying, ensuring smooth operations in the toughest arenas.

What Are PVC Belts Made Of?

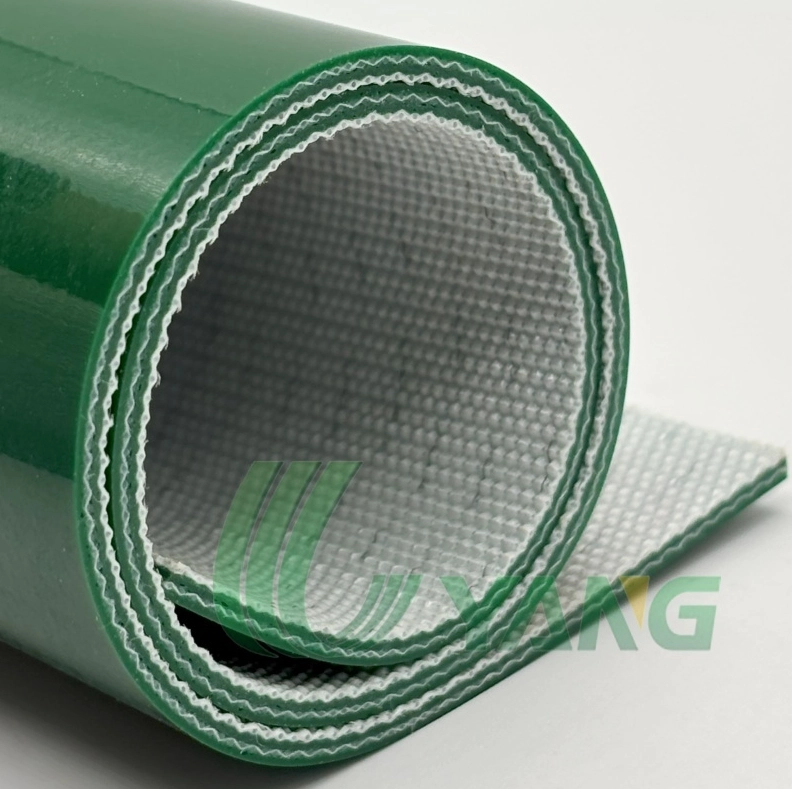

PVC belts, forged from polyvinyl chloride, dance with remarkable agility and defiance against chemical assaults. These featherlight yet resilient belts are perfect for industries like food processing, packaging, or gentle logistics tasks. Their glossy, smooth surfaces shrug off grime, making cleaning a breeze. Yet, under blistering heat or relentless abrasion, PVC belts may tire more quickly than their PVK counterparts, preferring gentler terrains where their strengths can shine.

Performance Comparison of PVK Belts and PVC Belts in Logistics Applications

Which Belt Offers Better Durability?

When durability takes center stage, PVK belts claim the spotlight. Their fortified design thrives under punishing conditions. They endure high-impact settings, like bustling warehouses or distribution hubs, with steadfast grace. PVC belts, though valiant, falter under heavy burdens or gritty surfaces. They’re sprinters, not marathoners, in the durability race.

How Flexible Are These Belts?

Flexibility is the secret sauce for navigating intricate conveyor paths. PVC belts pirouette effortlessly through tight curves and steep inclines. Their lithe, pliable nature makes them acrobats of the conveyor world. PVK belts, while no strangers to adaptability, lean toward brawn over bendiness. They prioritize unyielding strength, making them less nimble but fiercely reliable.

Which Has Superior Load-Bearing Capacity?

PVK belts flex their muscles in load-bearing contests. Their robust polyester core hoists heavy cargo—think industrial gear or bulk materials—with ease. They’re the workhorses of logistics. PVC belts, better suited for lighter fare like packaged goods or delicate food items, play a supporting role in less demanding scenes.

Environmental Resistance of PVK and PVC Belts

Can These Belts Handle High Temperatures?

PVK belts stand tall in fiery conditions. Their polyvinyl alcohol coating shrugs off heat, thriving in sweltering environments like steel mills or foundries. They’re cool under pressure. PVC belts, however, wilt under prolonged heat. Their structure craves milder climates, where they can perform without melting under the strain.

How Resistant Are They to Chemicals and Moisture?

PVC belts gleam in the face of chemical chaos. Oils, greases, and moisture slide off their slick surfaces, making them darlings of food processing plants where cleanliness reigns supreme. PVK belts hold their own against chemicals, but their true calling lies in mechanical might, not chemical defiance.

Do They Last Long in Harsh Conditions?

Both belts endure admirably when matched to their strengths. PVK belts, with their armored build, outlast others in brutal mechanical settings. They’re the knights of longevity. PVC belts, while resilient, may need more frequent curtain calls if thrust into heavy-duty roles beyond their comfort zone.

Operational Efficiency in Logistics Processes

How Energy Efficient Are These Belts?

Energy efficiency fuels cost-conscious logistics. PVC belts glide with minimal effort, their lightweight design and low friction sipping power sparingly. They’re the eco-warriors of conveyors. PVK belts, heftier by nature, demand slightly more energy. Yet, their unwavering reliability makes the trade-off worthwhile in high-stakes operations.

What About Maintenance Costs?

Maintenance shapes long-term budgets. PVC belts, with their sleek, dirt-repelling surfaces, ask for little upkeep. They’re low-maintenance stars. PVK belts, battling in grueling environments, may need regular check-ins to stay in fighting form. Their durability, though, often offsets the extra attention.

Do They Operate Quietly?

A quiet workplace boosts comfort and safety. PVC belts hum softly, their flexible composition muffling noise. They’re the whispers of the conveyor world. PVK belts, with their rigid frames, may chatter a bit louder. But in high-octane logistics hubs, their slight hum is a small price for their powerhouse performance.

Suitability for Specific Logistics Scenarios

In the intricate dance of logistics, picking the right conveyor belt can make or break efficiency. PVK belts soar in high-stakes, heavy-duty arenas—think airport baggage systems or automated warehouses—where resilience is king. PVC belts, meanwhile, dazzle in lighter, budget-conscious tasks like food processing or packaging, offering nimble adaptability and fuss-free maintenance. This guide illuminates where each belt shines, helping you align material to mission.

Where Do PVK Belts Excel?

Heavy-Duty Operations

PVK belts are the titans of tough tasks. Woven from polyester fabric and coated with polyvinyl alcohol, they boast unrivaled grit and staying power. They thrive in punishing settings, from airport baggage chaos to warehouse automation marathons. Their knack for shrugging off heavy loads ensures flawless performance where lesser belts would buckle.

High-Speed Conveying Systems

Speed is the lifeblood of modern logistics. PVK belts excel in rapid-fire material movement. Their sturdy build and tenacious grip prevent slippage, even at breakneck paces. E-commerce hubs and automated sorting facilities lean on PVK belts for their ability to keep the rhythm steady and swift.

What Are the Ideal Use Cases for PVC Belts?

Lightweight Material Handling

PVC belts are the nimble sprites of logistics. Their featherlight flexibility lets them weave through tight bends and steep slopes with ease. In food processing, packaging lines, or gentle logistics, they shine. Their glossy surfaces make hygiene a breeze, a must in sensitive settings.

Cost-Sensitive Operations

When wallets weigh heavy, PVC belts deliver. They’re budget-friendly without skimping on performance for lighter tasks. Low upkeep seals the deal, making them a savvy pick for industries juggling cost and efficiency. Heavy loads or abrasive materials, though, call for a different hero.

Recommendations Based on Uyang Belting’s Product Offerings

Why Choose PVK Belt Solutions from This Manufacturer?

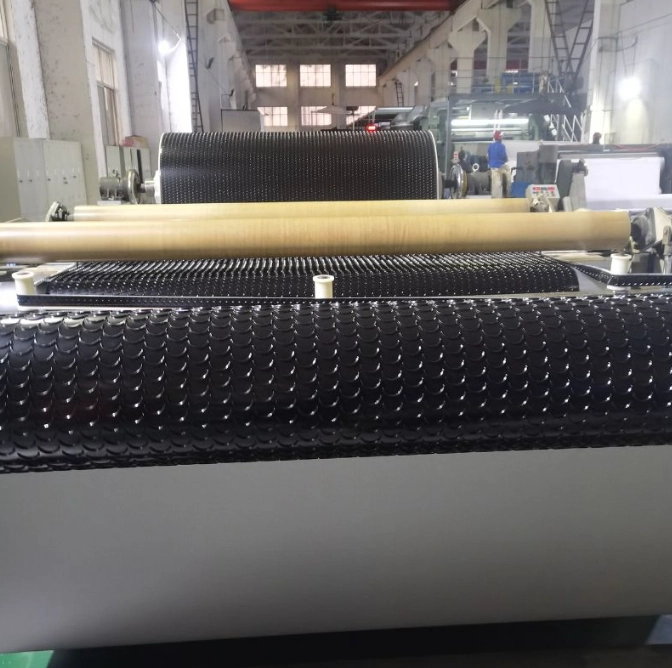

Uyang Belting’s PVK belts are forged for the logistics gauntlet. They brim with peerless wear resistance, ironclad tensile strength, and hefty load-bearing might. Tailored for punishing tasks like airport systems or warehouse automation, they promise steadfast reliability. Uyang Belting’s cutting-edge production, aligned with ISO 9001:2015, guarantees top-tier quality. For those craving robust, tailored solutions, their PVK belts are a beacon of excellence.

How Do Their PVC Belt Options Stand Out?

Uyang Belting’s PVC belts are a masterclass in versatility. Their supple flexibility and chemical defiance make them stars in lightweight material handling. With over 200 surface patterns, customization is limitless. FDA-compliant for food-grade tasks, they’re a hygienic powerhouse. For operations needing agile, cost-smart solutions, Uyang Belting’s PVC belts deliver with flair.

Choosing the Right Belt for Your Logistics Needs with Expert Guidance

Picking the perfect conveyor belt is a strategic art. Load demands, environmental quirks, and budget realities steer the choice. With over 20 years of conveyor belt mastery and a footprint in 50+ countries, Uyang Belting crafts solutions that fit like a glove. Their expertise ensures your operations hum with precision and power.

FAQ

Q1: Which belt type is better suited for high-speed operations?

A: PVK belts take the crown. Their robust build curbs slippage, ensuring seamless high-speed performance.

Q2: Are PVC belts resistant to chemicals?

A: Absolutely. PVC belts fend off oils, greases, and moisture, making them ideal for food processing.

Q3: Can PVK belts handle lightweight materials efficiently?

A: They can, but PVK belts are built for heavy-duty heroics. For lighter loads, their strength is overkill.