In tire making, conveyor belts act like quiet workers. They move stuff from mixing raw rubber to checking the final tire. If they stop, the whole place stops. Sudden belt breaks can cause long stops, lost stuff, and more work. Keeping belts going well without lots of fixes is a big problem for bosses in factories.

New tire plants now use smarter, tougher belt setups. These cut fix costs and make things more steady. With many years in the tire and rubber field, UYANG BELTING gives modular conveyor belts made for hard jobs and hot spots. This helps makers keep making tires with fewer stops.

1. Choose the Right Belt Type for Each Production Stage

Not every conveyor belt in a tire factory does the same task. The setting and how stuff moves change a lot between mixing, cooling, shaping, heating, and checking steps. A belt that works fine in one spot might break fast in another.

For instance, in the mixing spot, the rubber mix is sticky, warm, and heavy. This needs a belt with good grip and heat strength. But in cooling and checking lines, steady and smooth moving matters more than hold.

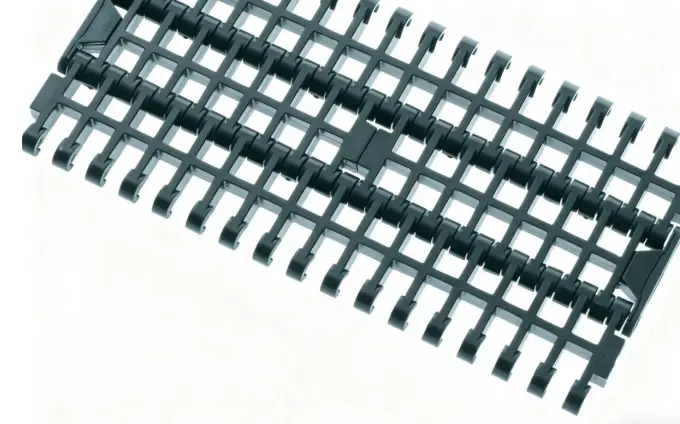

UYANG BELTING offers various modular belt styles made for these spots. Models like the UY-900A Flush Grid and UY-900C Thickening Flush Grid deal with hot stuff well. They also keep air flowing for quicker cooling. For areas that need a clean, flat top—like checking treads or sorting—flat-top series belts such as UY-900D Flat Top and UY-1000 Flat Top hold tires steady during moves. And they make cleaning simple.

By picking the belt style that fits the exact job, factories can cut extra wear. This makes the belt last much longer.

2. Focus on Heat and Chemical Resistance

Hot temps and chemical contact are hard to avoid in tire making. During mixing and heating, belts often face 100°C to 180°C warmth. They touch oily rubber or chemical stuff all the time.

This is where modular plastic belts help a lot. Belts from POM or PP stuff can take heat and chemicals better. They stay steady under big loads for many hours. They also fight sticking. So, even soft or tacky rubber mixes slide easy on the line.

Among UYANG’s best picks for warm areas are the UY-1400 Embedded Diamond Top and UY-1700 Open Grid Series. Both are made for long contact with heat and oil. These belts help lower belt swaps and cut stops. This saves fix teams hours of work each month.

Changing to belts that fight heat more might cost more at first. But the gain in lasting time and less fixes soon beats the start cost.

3. Keep Belt Alignment and Tension in Check

Belts that are off line are a quick way to waste cash in a making line. When a belt shifts from center or runs too tight, it can cause uneven rub, more sound, or harm to the machine. Over days, this also boosts power use.

Normal checks of wheel line-up, belt path, and pull levels make a real change. Modular belts make this simpler. They use linked parts that can be fixed or swapped in bits. This lets fix teams solve line issues fast without pulling the full line apart.

UYANG BELTING gives strong wheels, like those in the UY-4000 Series. These offer exact fit and smooth belt moves. This mix of steady wheels and right pull helps the belt last longer. It also keeps the whole setup running well.

4. Schedule Preventive Maintenance Instead of Emergency Repairs

Lots of tire factories still deal with belt fixes only when issues show up. They wait until a problem hits before acting. But by that point, it’s often too late. A ripped or burned belt can close a full making line.

Preventive fixes don’t need to be hard. A basic plan that covers eye checks, cleaning, and looking for splits or chain rub can cut sudden breaks a lot. Keeping a simple fix record helps find repeat problems before they make big trouble.

One good plus of UYANG’s modular belt setups is how easy they are to mend. If one part wears out, it can be changed right there in minutes. You don’t need to take off the whole belt. That means fewer stops and less lost stuff.

By moving from a “mend it when it fails” way to a “look at it before it breaks” plan, tire plants can keep steady output. This also holds fix budgets down.

5. Choose Long-Life, Low-Maintenance Belt Systems

In busy making, every second matters. Putting money in top-notch, easy-to-care-for belts can change plant work a lot. Modular belts from UYANG BELTING are built for that—tough, steady, and simple to fix.

Their belts are made for hard tire making spots. They offer strong hold for loads, great fight against rub, and low slide work. For example, the UY-3500C Nub Top is fine for moving rough rubber tops. While the UY-4400 Big Transverse Roller Top deals with heavy or done tires well on slopes or pile-up lines.

Unlike old rubber or PVC belts that need often pull tweaks or joins, modular belts keep their form and work over time. The linked style also means a single hurt part can be changed out. You don’t swap the full belt.

Over days, this not only lowers extra part costs but also cuts making breaks. This leads to better total output and lower price per tire made.

Conclusion

Cutting conveyor belt fix costs in tire making isn’t about skipping steps. It’s about using smarter, tougher tech and caring for it all the time. Picking the right belt kind, keeping good pull, setting normal checks, and putting in modular fixes all help make smoother, longer work.

UYANG BELTING has earned its name by helping the tire and rubber field with strong, steady conveyor answers. With over 20 years of making know-how, the firm keeps aiding tire plants worldwide. They cut fixes, boost up time, and get better work on each making line.

FAQs

Q1: What kind of conveyor belts work best in tire factories?

A: Modular belts made from POM or PP are great for tire making. They fight heat, oil, and wear. They are also easy to clean and care for compared with old PVC belts.

Q2: How often should conveyor belts be checked in a tire plant?

A: A fast look every two to four weeks is suggested. This helps find line-up issues, worn wheels, or pull problems early. It stops them from making bigger harm.

Q3: Why switch to modular plastic belts instead of rubber or fabric belts?

A: Modular plastic belts last longer and handle big loads better. They can be fixed in parts. This cuts stops a lot and lowers total fix costs across tire making lines.