PVK conveyor belts, crafted from durable PVC-polyester materials, are engineered for high-performance logistics automation, offering superior wear resistance, anti-static properties, and customizable designs. Ideal for warehouses, sorting centers, and industrial applications, these belts enhance efficiency with high-friction surfaces, temperature resilience (-30°C to 80°C), and noise-reducing operation. Uyang Belting’s PVK solutions reduce downtime by 40% through smart monitoring compatibility and require minimal maintenance.

What Are PVK Conveyor Belts?

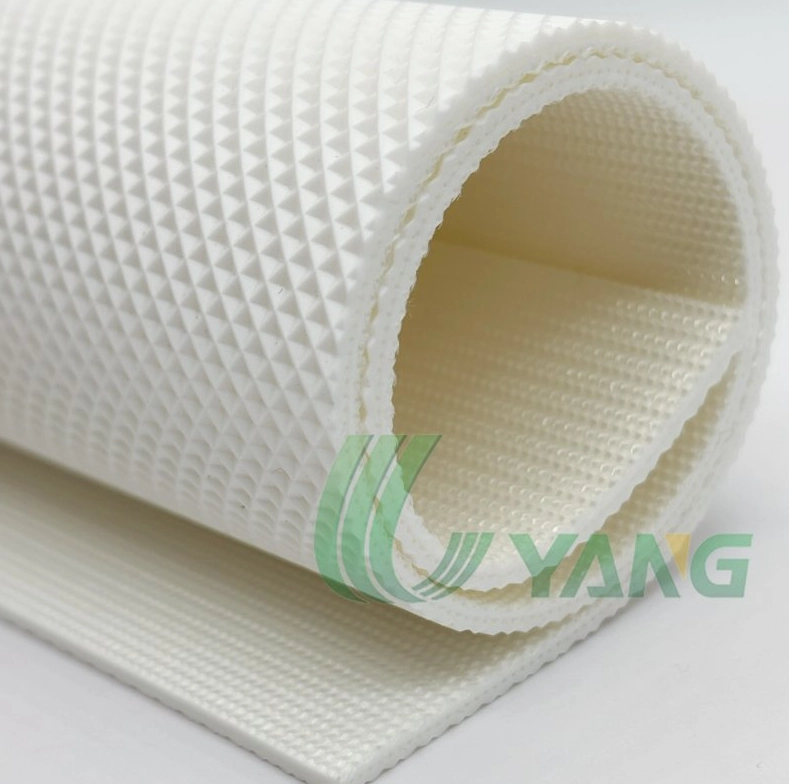

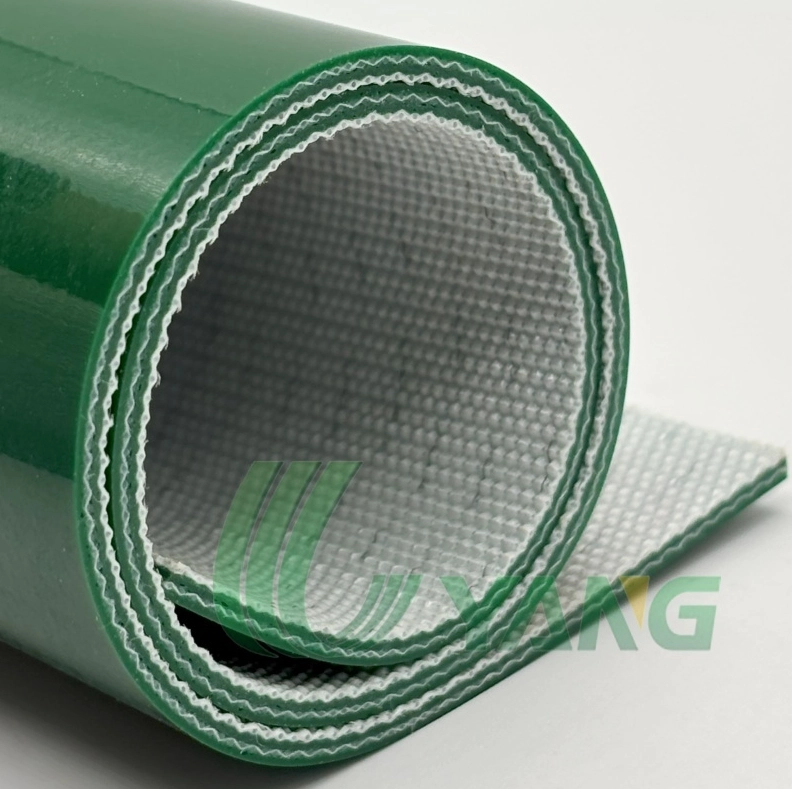

PVK conveyor belts are a kind of conveyor belt made for high-performance uses in sectors such as logistics and the automation industries. These belts are crafted with polyvinyl chloride ( PVC ) and polyester fabrics to provide a combination of strength, flexibility, and resilience to wear. Their makeup enables them to be ideal for challenging settings that require precision and dependability. These belts are especially prized in automated setups for their functionality across different scenarios.

Why Are PVK Conveyor Belts Ideal for Automation?

What Makes PVK Belts Durable and Resistant?

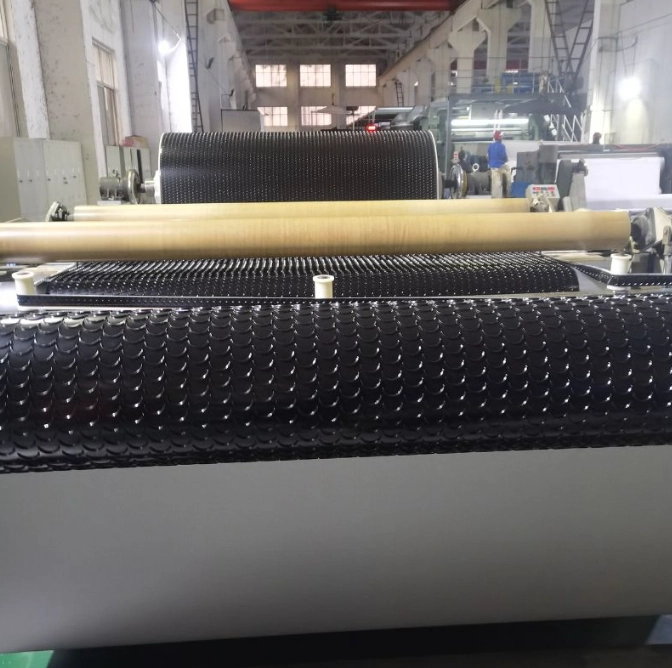

PVK conveyor belts are known for their build quality that enhances their longevity in demanding environments like mining and manufacturing industries, where toughness is essential for continuous operations without frequent replacements needed due to their resistance to wear and tear as well as mechanical strain.

How Do Anti-Static Features Enhance Performance?

Ensuring that there are measures in place to prevent electricity loss is important in places like electronics manufacturing or logistics automation, where sensitive equipment is used. PVK conveyor belts are effective at reducing charges, which helps maintain safety and prevents damage to delicate components. Additionally, the belts are designed to operate, which creates a more peaceful working environment for operators and helps reduce noise pollution.

Why Is High Friction Surface Important?

In material handling operations, it is crucial to have a surface with friction to ensure stability and control of the goods being transported efficiently. PVG belts are known for their ability to grip transported items securely and prevent slips even when dealing with steep inclines or fast movements. This quality proves advantageous in automated logistics setups where accuracy and precision play a vital role in operations.

How Do PVK Conveyor Belts Improve Logistics Automation?

Can They Boost System Efficiency?

In the field of logistics automation, achieving efficiency is crucial. PVK conveyor belts play a role in ensuring smooth material flow by reducing interruptions caused by belt issues or misalignment. They consistently deliver performance to enable automated systems to run smoothly without any unnecessary interruptions. This reliability leads to processing times and enhanced productivity.

How Do They Ensure Material Handling Precision?

Accurate handling of materials is crucial for activities like organizing items for shipment and delivery purposes. PVH belts with their high friction surface play a role in ensuring the precise placement of goods while in transit. Their ability to prevent electricity buildup further aids in maintaining exact processes in settings where even slight variations can result in notable productivity losses.

Can Reliable Belt Performance Reduce Downtime?

Having periods of inactivity can really throw a wrench in business operations. Result in increased costs, for fixing and maintaining equipment to ensure everything is running smoothly again. The PVX conveyor belts have been crafted to provide lasting performance while demanding minimal maintenance from users or maintenance teams overseeing them. They are built to be durable and withstand wear and tear over time, ultimately decreasing the chances of breakdowns or malfunctions. This allows companies to concentrate effectively on boosting productivity rather than dealing with repair concerns constantly.

What Should You Consider When Choosing a PVK Belt for Logistics?

Are Load Capacity and Strength Critical Factors?

When choosing a PVK conveyor belt for logistics purposes, it is important to take into account the load capacity and tensile strength needs of your system. Medium-weight PVK belts are commonly favored in sectors such as cement production or recycling facilities because they can carry loads without sacrificing efficiency. In 2024, the medium weight segment alone was estimated to be worth $ 2.5 billion.

Does Environmental Adaptability Matter?

Environmental elements play a part in deciding if a conveyor belt is appropriate for use.

Can They Handle Extreme Temperatures?

PVK belts are crafted to function over a broad range of temperatures – be it in cold or scorchingly hot settings; these belts retain their flexibility and structural strength.

Are They Resistant to Moisture and Chemicals?

Over time with exposure to moisture and chemicals can cause regular conveyor belts to deteriorate in quality and strength. PVK conveyor belts are resistant to these elements, making them a great choice for use in situations where there is contact with oils or chemicals or in damp environments.

Are Customization Options Available?

Tailoring is frequently essential to address operational requirements effectively. Whether it’s adjusting measurements or crafting surface designs suited for specialized uses such as airport logistics or food processing needs, personalization guarantees that your conveyor belt fits seamlessly with the demands of your system. Discover tailored solutions designed specifically to cater to the demands of your industry here.

Recommendations for Integrating Uyang Belting’s PVK Conveyor Belts

Belts from Uyang Belting labeled PV Polyester come with a PVC polyester build to meet the needs of rigorous logistics operations effectively. These belts can be customized in terms of size and surface features to seamlessly integrate into any system and boast static qualities that aid in automation. Perfect for warehouse and sorting setups, these belts require upkeep and help minimize operational disruptions thanks to their exceptional durability against wear and tear.

Overview of Uyang Belting’s Product Range

What Specialized PVK Conveyor Belt Models Are Available for Logistics?

PVK conveyor belts are crafted to meet the demands of the logistics and automation sectors by blending polyvinyl chloride ( called PVC) with polyester materials for long-lasting strength and protection against wear and tear. These belts excel in performing duties with precision. They are indispensable in settings such as warehouses, sorting hubs, and distribution centers. In automated environments where dependability and productivity are paramount, these belts showcase their efficiency.

How Do Tailored Solutions Cater to Complex Systems?

Tailored solutions play a role in managing intricate logistics systems that demand special requirements to function effectively. Uyang Belting offers personalized PVK conveyor belts that are tailored to meet operational demands such as dimensions, surface designs, and specialized coatings. These customizations guarantee an integration into current systems and improve overall performance while reducing the chances of operational hitches.

Key Benefits of Choosing Uyang Belting Products

Why Is Enhanced Longevity Important?

The durability of conveyor belts impacts both costs and the effectiveness of existing systems in operation. PVK conveyor belts are engineered for longevity to reduce the frequency of replacements and minimize downtime. Their resilience against wear and tear and mechanical stress guarantees performance even in demanding conditions, making them a viable choice for companies seeking to optimize their logistical operations.

How Does Compatibility with Advanced Automation Technologies Add Value?

In today’s age of innovation and technological advancements pushing us forward, it is essential for businesses to smoothly integrate the technologies into their processes seamlessly and effectively forge ahead with automation trends. The PVK conveyor belts are crafted with precision to seamlessly integrate with automated systems in a manner that blends into the workflow efficiently and effectively. These belts come equipped with features that play a crucial role in preventing the accumulation of static electricity, an important factor for ensuring safety in delicate settings such as electronics manufacturing facilities or automated warehouses where sensitive equipment is utilized. Moreover, their quiet operation adds to the atmosphere at work, promoting a peaceful environment for employees.

Installation and Maintenance Best Practices

What Are Proper Installation Techniques for Optimal Performance?

It’s crucial to install PVK conveyor belts to make sure they work efficiently and last long term in operational settings. Rechecking the alignment from the get-go helps avoid problems such as misalignment or uneven wear. Also crucial is getting the belt tension; too much tension can wear out the belt prematurely, and too little can result in slipping issues.

Why Is Regular Inspection Essential?

How Can Wear and Tear Be Identified Early?

Catch signs of damage early to prevent repairs or replacements by regularly checking for frayed edges or cracks on the belt and listening for any unusual sounds during use. Addressing these issues promptly will ensure consistent performance over time.

What Cleaning Practices Maintain Belt Efficiency?

Ensuring the cleanliness of PVH conveyor belts is essential for keeping them running efficiently at their performance levels. Prolonged accumulation of dust, dirt, or chemical deposits can affect traction and overall functionality of the belts. It is important to utilize cleaning products that are safe for the belt material in order to promote longevity and ensure smooth operation.

Future Trends in Logistics Automation with PVK Conveyor Belts

What Innovations Are Driving Industry Growth?

The transportation sector is experiencing changes due to the improvements in conveyor belt technology. Incorporating monitoring tools into PV belts enables the real-time monitoring of key performance indicators, like speed, tension, and temperature. This progress supports maintenance efforts in decreasing unforeseen operational disruptions.

How Will Sustainable Materials Shape Future Designs?

The importance of using materials in the production of conveyor belts is growing significantly. Materials such as PVC, which are polymer-based, provide great durability and can be recycled. This move, towards friendly options, supports worldwide initiatives to lessen environmental harm while still maintaining high performance levels.

FAQs

Q1: Can PVK conveyor belts be used in high-temperature environments?

A: Yes, PVK conveyor belts are designed to perform reliably across a wide range of temperatures without losing flexibility or structural integrity.

Q2: How do anti-static properties improve safety in logistics systems?

A: Anti-static features prevent static electricity buildup that could damage sensitive electronic components or create sparks in hazardous environments.

Q3: Are there customization options available for specific industries?

A: Yes, customization options include tailored dimensions, surface patterns, and specialized coatings to meet unique operational requirements. Learn more about customized solutions here.