The UYANG Green PVC Straight Rib Conveyor Belt is designed for applications requiring enhanced surface grip and stable conveying performance, especially on inclined or slightly sloped conveyors.

The straight ribbed surface structure improves friction between the belt and conveyed materials, reducing slippage and ensuring controlled product movement. It is suitable for light to medium-duty industrial conveying environments.

The UYANG Green PVC Straight Rib Conveyor Belt is designed for applications requiring enhanced surface grip and stable conveying performance, especially on inclined or slightly sloped conveyors.

The straight ribbed surface structure improves friction between the belt and conveyed materials, reducing slippage and ensuring controlled product movement. It is suitable for light to medium-duty industrial conveying environments.

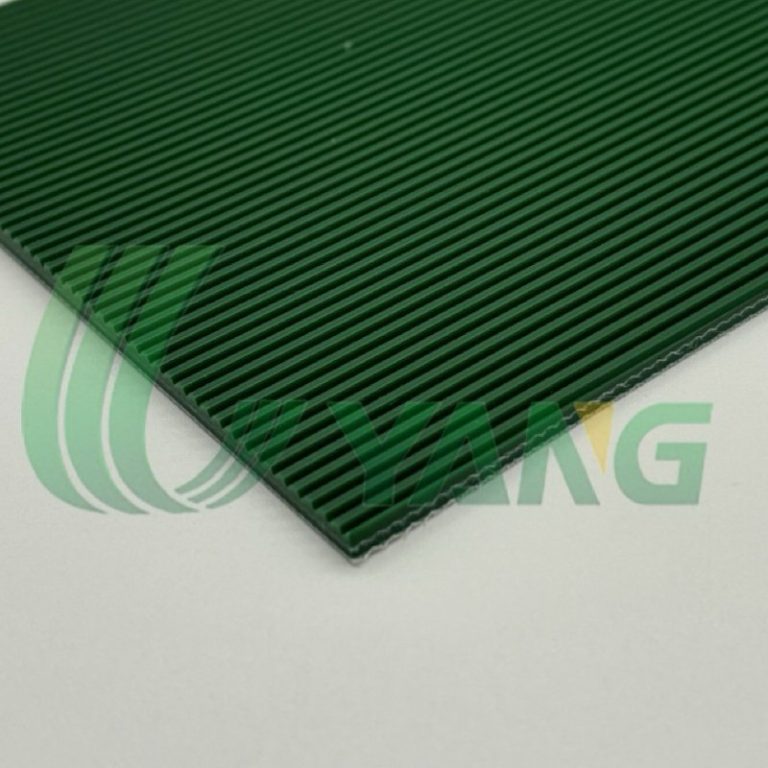

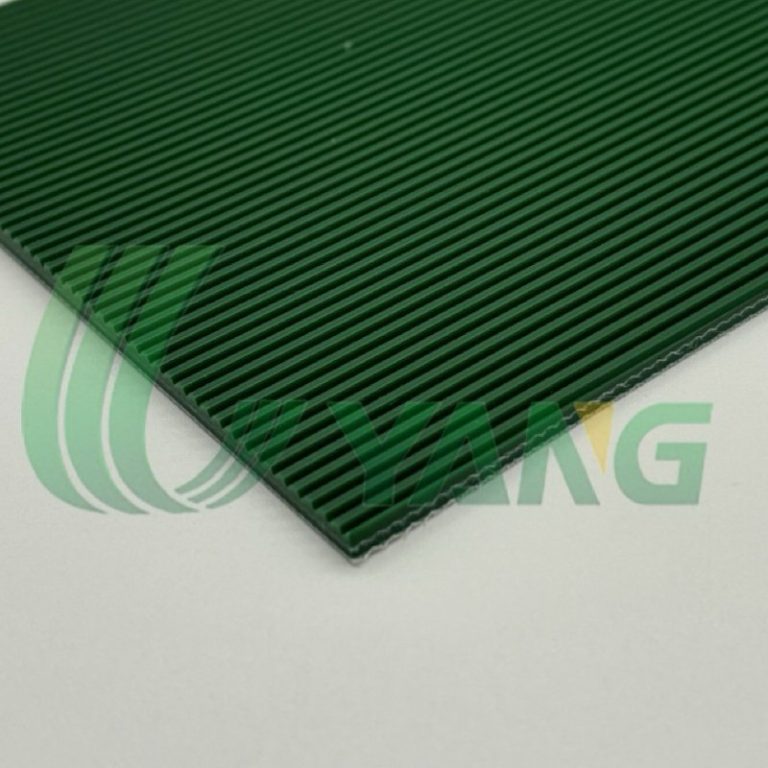

Top Cover: Green PVC with straight rib pattern

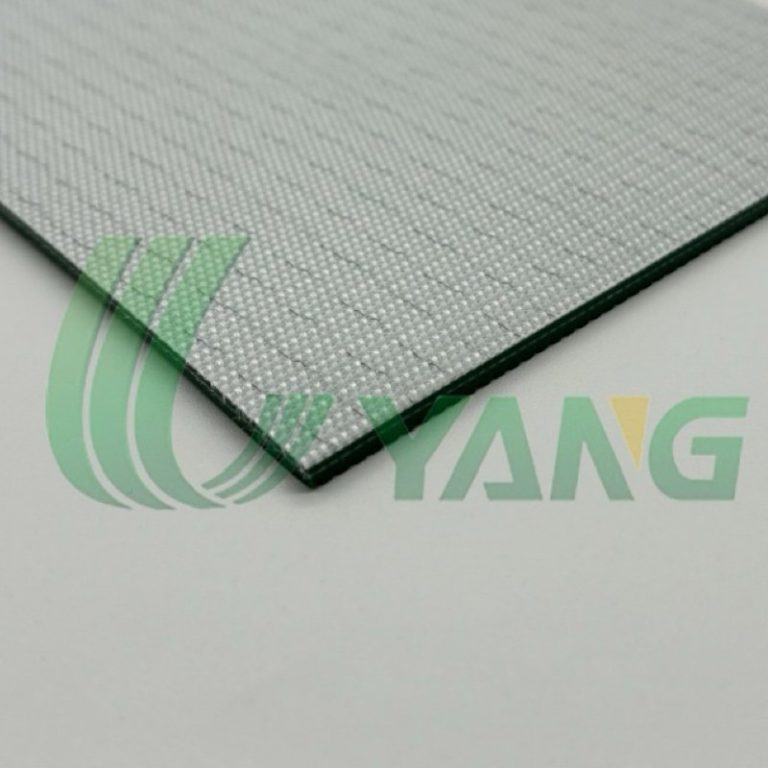

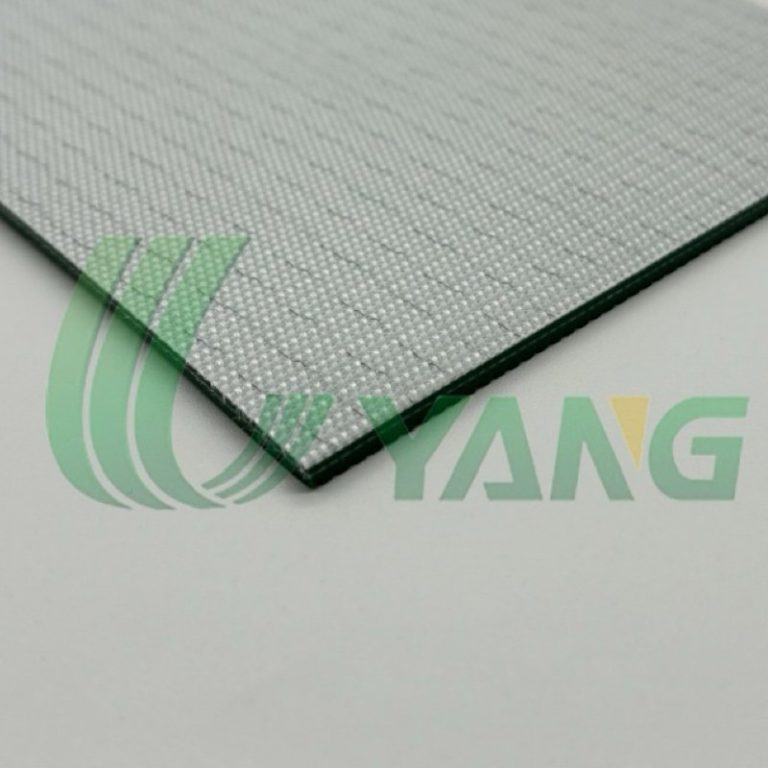

Carcass: Multi-ply polyester fabric reinforcement

Bottom Surface: Fabric backing

Surface Type: Linear ribbed (anti-slip structure)

Operating Temperature: -10°C to +80°C

Antistatic option available

The linear rib pattern:

Increases surface friction

Prevents product rollback on inclined conveyors

Improves stability during transport

Provides directional grip performance

The PVC top layer offers:

Good abrasion resistance

Resistance to moisture and light industrial chemicals

Easy maintenance

Multi-layer polyester carcass ensures:

High tensile strength

Controlled elongation

Stable tracking performance

Ideal for:

Inclined transfer conveyors

Packaging lines

Logistics sorting systems

Agricultural product conveying

Light industrial material handling

Carton box conveying

Bagged product transport

Vegetable & fruit processing

Warehouse distribution systems

General light-duty industrial lines

In inclined conveying systems, smooth belts often cause product slippage.

The straight rib pattern:

Provides consistent grip along the conveying direction

Balances friction and wear

Reduces product movement instability

Improves operational safety

It is a practical solution for applications requiring controlled incline transport without excessive belt thickness.

Endless fabrication

Cleats and sidewalls

Different rib heights

Various thickness and ply configurations

Custom width and length

Before recommending the correct belt specification, we confirm:

Incline angle

Product weight and surface condition

Conveyor speed

Required load capacity

Environmental exposure

Correct belt structure selection ensures longer service life and stable operation.

Reliable delivery schedules and warehousing support.

Competitive pricing to maximize overall value.

Diverse options to cater to all market segments.

Flexible MOQ Support with all types of goods;

Personalized logo customization on the products

Provide online technical support for all product usage and installation processes

Quick first response to all inquiry and questions

Provide quality images, Video to enhance sales revenue

Efficient production and ship within 15 days at the fastest.

Generally it is 10-15 days, if peak season, it will be about 15-20 day safter receiving the deposit

1. Confirmed Specification: thickness,color, plies,characteristic, and industry;

2. Samples sending: we send samples for you check.or you send us samples if customized belt.

3. Confirm Order: Signing sales contract after samples confirmed.

4. Deposit: 30% deposit before mass production.

5. Production arranged : we will process the production.

6. Remaining payment: after inspection, balance before shipment.

7. Shipping: we will ship the goods to destination port.

8. Confirm bill of loading/commercial invoice/packing list/certificate of origin;