Livestock conveyor belts tackle tough challenges daily. They endure rough treatment, sticky messes, and heavy loads that can slow down work and cut efficiency. This guide dives into frequent troubles like crooked belts, slipping, and wear while sharing smart fixes, such as precision alignment tools, perfect tension tricks, and easy-to-maintain designs. Learn how picking the right materials and staying ahead with care can boost strength and performance in harsh farm settings.

Common Issues Found in Livestock Conveyor Belts

What Are the Signs of Wear and Tear on Conveyor Belts?

Livestock conveyor belts work hard, but over time, they start showing their age. Look for cracks, frayed edges, or thinning spots. These problems often come from hauling heavy loads and rubbing against rough stuff. Odd noises or shaky movements might also mean there’s hidden damage inside.

Why Do Misalignment Problems Happen in Conveyor Systems?

When belts run crooked, trouble follows. Misalignment usually starts from a sloppy setup or slow shifts in the frame due to outside pressure. A wonky belt wastes energy and shortens its life.

How Do Slippage and Belt Tension Issues Mess Up Work?

Slipping happens when the belt loses its hold on the pulleys, often because it’s too loose. This slows things down, making materials move unevenly. Cranking the tension too high strains the belt and parts, leading to early breakdowns.

What Causes Gunk to Pile Up on Conveyor Belts?

Sticky stuff like feed or manure loves to cling to belts. This buildup blocks smooth movement and speeds up wear.

Finding the Root of Conveyor Belt Breakdowns

How Can You Catch Mechanical Failures Early?

Machines talk—if you listen. Jerky belt moves or sudden stops often mean bad rollers, busted pulleys, or weak joints. Checking often helps spot these before they wreck the system.

How Do Weather and Conditions Affect Belt Life?

Heat, dampness, and chemicals are no friends to Livestock Conveyor Belts. Humidity rusts metal parts, while scorching heat can melt or weaken certain materials.

Are Bad Setup or Skipped Maintenance to Blame?

A rushed install spells disaster. If belts aren’t lined up right from the start, stress piles up unevenly. Skipping cleanings and lubes only makes wear worse.

Smart Fixes for Conveyor Belt Troubles

Keeping belts straight and well-tuned is key for smooth farm work. Crooked belts, slips, and grime slow everything down. Here’s how better alignment tools, grip boosters, and clever designs can cut downtime and stretch belt life.

How Do You Straighten and Align Conveyor Systems Right?

Fixing Crooked Belts

To straighten a belt, adjust the pulleys and balance the tension side-to-side. Laser tools make this step pinpoint accurate.

Tools to Track Alignment Over Time

Sensors that watch alignment non-stop give real-time alerts, stopping small issues from becoming big headaches.

How Can You Stop Slipping and Set Perfect Tension?

Keeping Tension Just Right

Too loose? The belt slips. Too tight? It strains. Hand-crank tensioners or auto-sensing systems keep the sweet spot.

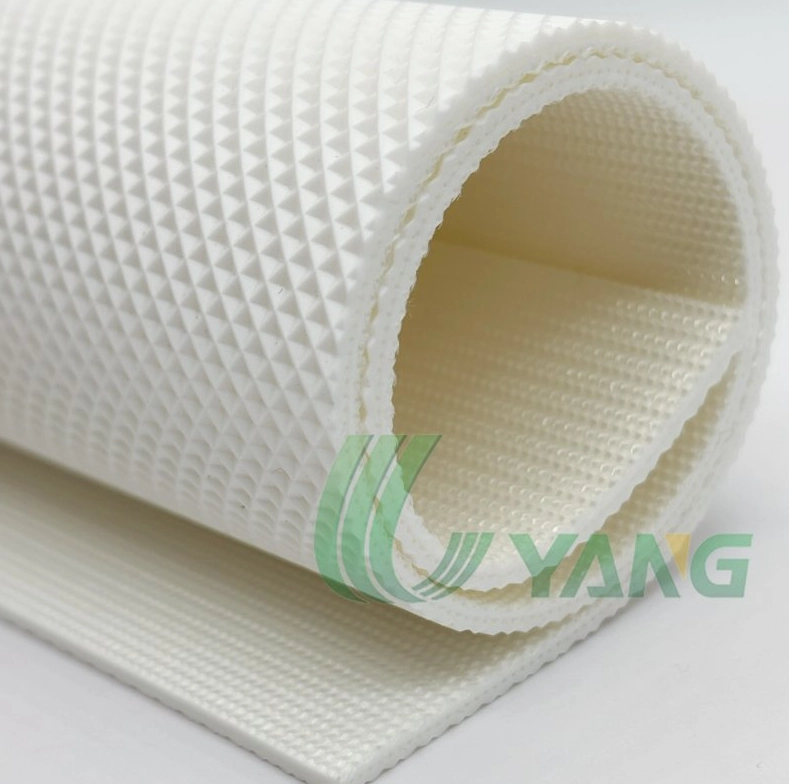

Grip-Boosting Tricks

Textured belts or special coatings add traction, even when things get messy.

What Stops Gunk from Sticking to Belts?

Easy Cleaning Tricks for Farm Belts

Scrapers and brushes made for Livestock Conveyor Belts clear muck fast. Self-cleaning setups save even more time.

Belts That Fight Filth

Non-stick surfaces shrug off clingy messes, making upkeep a breeze.

Picking Tough Livestock Conveyor Belts That Last

Choosing the right belt keeps farms running smoothly. Top-notch belts must stand up to heat, scratches, and chemicals while fitting each farm’s unique needs. Here’s what to look for—tough materials, smart designs, and custom tweaks—so you get gear that goes the distance.

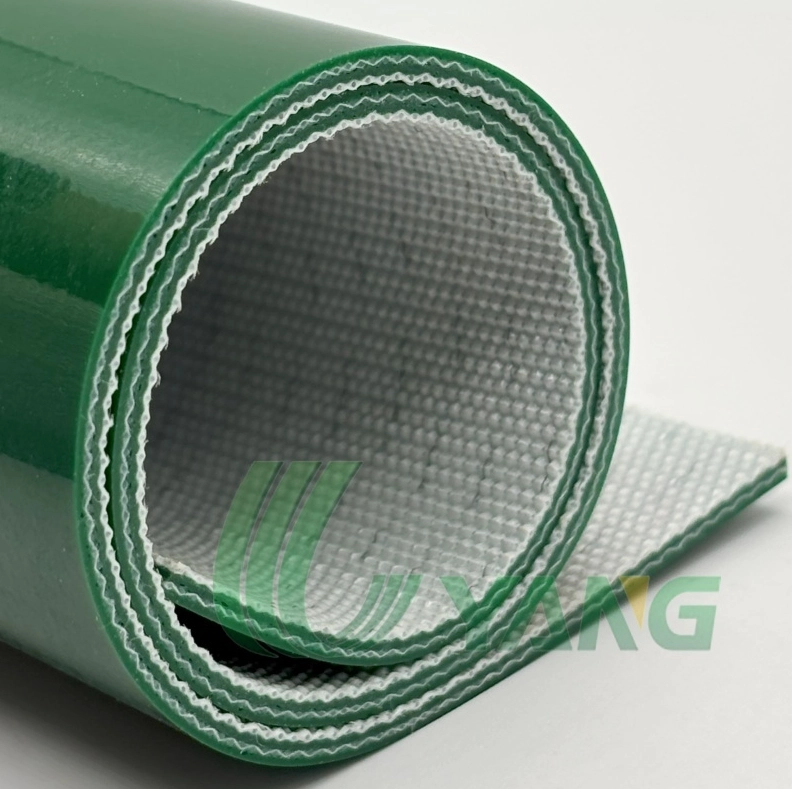

What Makes a High-Quality Conveyor Belt?

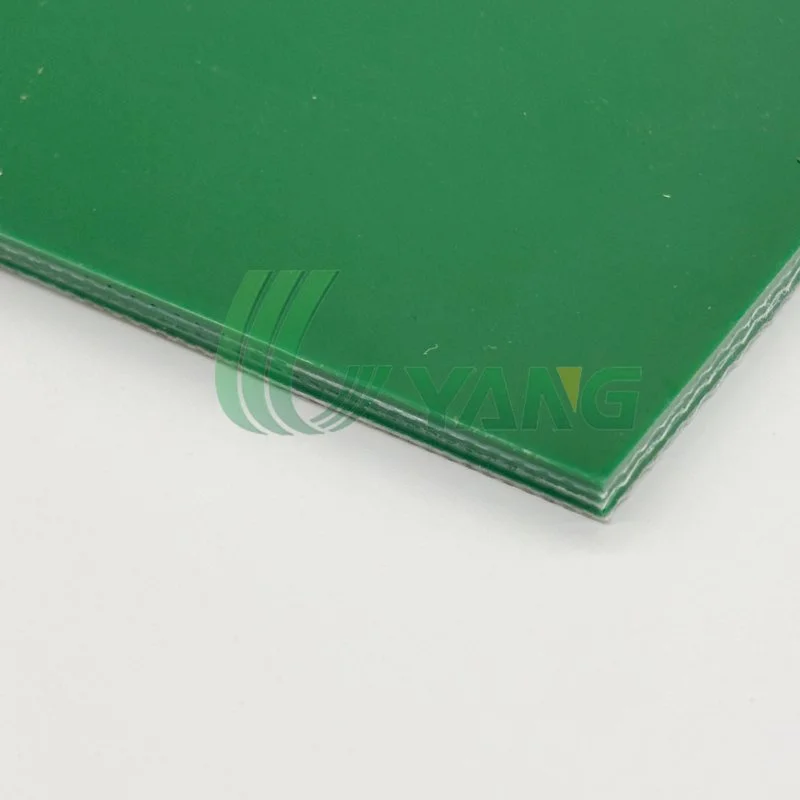

Why Heat, Scratch, and Chemical Resistance Matter

Livestock conveyor belts face brutal conditions. They need to handle heat, sharp feed bits, and harsh cleaners. Rubber belts muscle through heavy jobs, while PVC suits lighter tasks like moving feed. Need food-safe options? PU belts are the go-to.

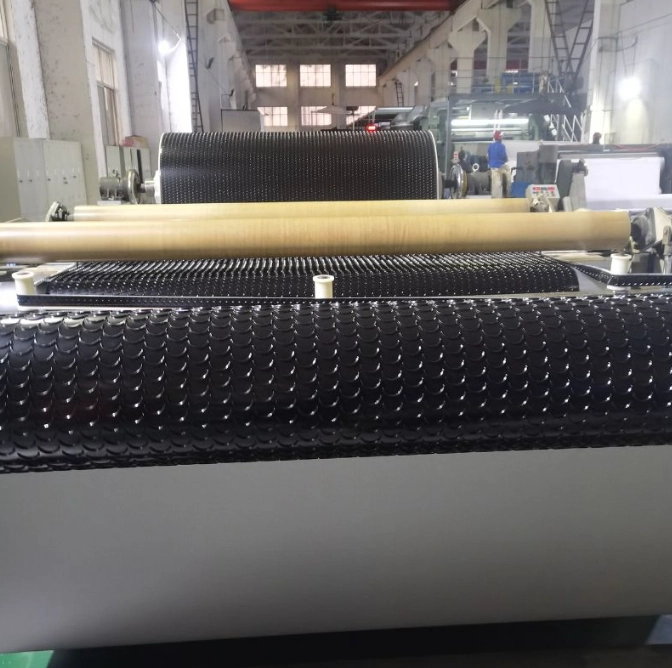

Why Uyang Belting’s Farm-Ready Belts Shine

For two decades, Uyang Belting has led the pack with clever fixes for tough jobs. Their belts meet top standards and tackle farm challenges head-on. Specialty textures and materials make their gear a perfect match for barns and fields.

Tailoring Belts to Fit Your Farm

One-size-fits-all doesn’t cut it. Custom picks—like special surfaces or sizes—fine-tune belts for your exact needs, whether battling abrasive feed or keeping things germ-free.

Staying Ahead with Smart Maintenance

Setting Up Regular Check-Ups

Catching small issues early saves big repairs later. Weekly peeks at belts for cracks, fraying, or misalignment keep surprises at bay. Spotting worn rollers or shaky pulleys fast means less downtime.

Why Uyang Belting’s Easy-Care Designs Win

Belts built for simple upkeep save time and sweat. Non-stick tops and self-adjusting tension mean less hands-on fuss. Uyang Belting’s focus on smart design means their belts last longer with less work.

Teaching Teams to Handle Belts Right

A trained crew keeps belts humming. Regular drills on setup, tension tweaks, and cleaning build know-how that keeps gear running smoother, longer.

FAQs

Q1: Why pick PVC for Livestock Conveyor Belts?

A: PVC fights off chemicals and bends easily, perfect for hauling feed and light loads.

Q2: How do I stop belts from running crooked?

A: Check frames often and use laser tools during setup to keep stress even.

Q3: Are there belts that clean up easy?

A: Yes! Non-stick surfaces and auto-tension systems slash maintenance time.