China now serves as a major global center for producing PVC conveyor belts. Industries from food handling to basic material transport depend more and more on Chinese makers for steady quality, large-scale output, and quick delivery times. Every tough PVC conveyor belt comes from a careful production method that mixes material knowledge, strict process management, and designs suited to actual use.

UYANG BELTING shines in this field because it stresses reliable materials, managed production phases, and items made to fit everyday working setups. Knowing how these belts get built lets buyers assess lasting results, rather than just outer looks or low costs.

What Are The Key Stages In The Manufacturing Process?

The strength of PVC conveyor belts does not arise by luck. Instead, it forms gradually, from picking raw materials to the last check. And each part clearly shapes how the belt works when set up in a factory line.

Before we detail each phase, remember that solid makers view the whole method as a linked chain. So, any loose control in one spot tends to appear later as quick breakdown, unwanted pull, or outer harm while in action.

Raw Material Selection And Preparation

The production starts with choosing materials. Top-grade PVC resin along with support fabrics form the base of a firm belt. In many PVC conveyor belts, polyester fabrics act as the inner layer since they give a fair mix of power, bendability, and budget-friendly pricing.

Preparing materials counts too. So, PVC mixes need even blending to reach uniform firmness, shade, and resistance to chemicals. If blending stays uneven, it can cause soft areas on the belt’s top, and those spots turn into break points in tough work settings later on.

UYANG BELTING puts heavy focus on steady materials, particularly for belts in food areas and basic industry spots where top stability and easy cleaning stay essential.

Layering And Calendaring Process

With materials ready, the belt’s build forms via layering and pressing. So, backed fabric sheets join with PVC covers under set pressure and heat levels. This phase sets the belt’s depth, pull strength, and bend range.

The pressing step lets the PVC sheet stick smoothly to the fabric base. And exact work here makes sure the belt travels straight and fights off edge wear as time passes. For belts with several layers, right positioning among them proves vital, above all in tasks with non-stop running.

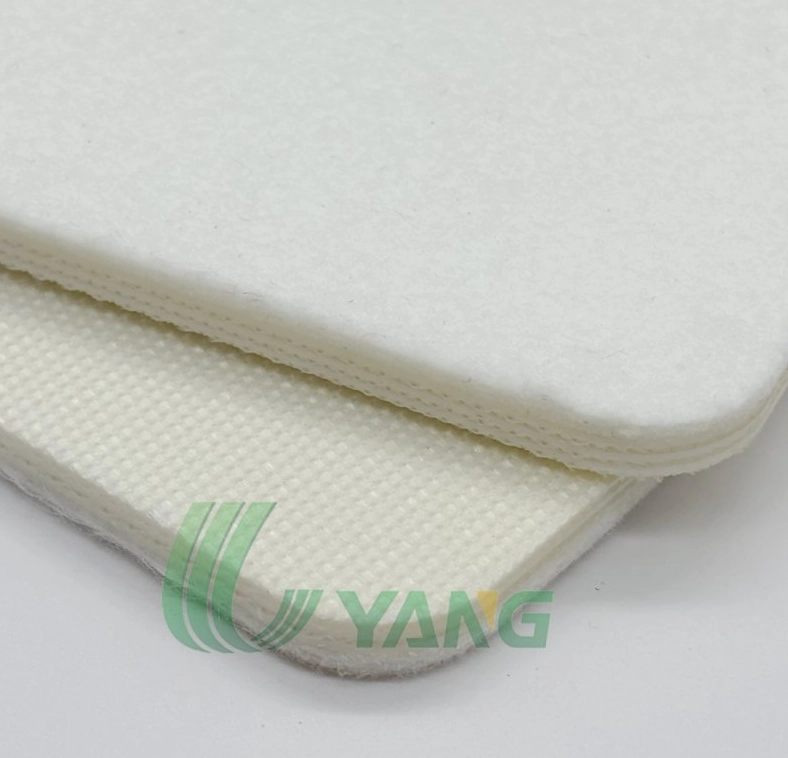

Items such as the 3-Ply White Felt Bakery Conveyor Belt depend a lot on this phase to keep both a gentle top and solid build below.

Curing, Cooling And Quality Inspection

Once layering ends, belts face heat setting to firm up their form. So, managed warmth lets the PVC fully join the fabric, and this locks in power and outline. If setting happens fast or patchy, it often creates inner strain, which cuts belt lifespan.

Then cooling comes slowly to avoid twists. After it cools, belts move to check points where depth, outer finish, and pull traits get tested. And trusted makers see checks not as a simple task but as a key barrier before sending out.

UYANG BELTING uses several check spots to spot problems soon, and this cuts the chance of uneven groups going to clients.

Why Does Manufacturing Process Matter For Belt Performance?

A conveyor belt might seem alike at first glance, but real differences show up after months in service. So, the production method shapes how the belt deals with weight, rub, and regular use. And grasping this link lets buyers look past simple details and aim for ongoing worth.

Enhanced Wear Resistance Through Material Engineering

Resistance to wear goes beyond just depth. Rather, it relies on how well the PVC mix stands up to scrapes and sticks tight to the fabric base. Weak sticking often causes top layers to lift, particularly in belts facing constant rub.

UYANG BELTING crafts its PVC recipes to hold top firmness even during many on-off runs. And this matters a lot for dull and even-top belts in packing and sorting setups.

Improved Belt Stability And Load-Bearing Capability

Steadiness impacts path-keeping, pull management, and full setup output. A properly made belt holds its form under weight and fights stretch as days go by. So, this lessens the call for regular pull adjustments and drops upkeep expenses.

The inner fabric build, paired with careful layering, takes a big part here. Belts with shaky bases often shift or shake while working, and that brings stoppages that could have stayed away.

Customization Meets Diverse Industry Needs

Not every conveyor setup matches the next. So, food handling, shipping, and basic making each set unique calls on belt tops and power. A bendable production method lets makers tweak top feel, depth, and shade without losing evenness.

UYANG BELTING backs tailored specs for original makers and setup builders, and this makes its belts fit many fields without making output too complex.

How UYANG BELTING Products Exemplify Top-Tier Quality

Production strength shows clearest when we look at set items. UYANG BELTING’s line of PVC conveyor belts mirrors its method-focused way, with each build linked tight to use demands.

Before we go over single products, it pays to note that these belts do not form alone. Each one stands for a mix of material picks, top builds, and input from real use.

3-Ply White Felt Bakery Conveyor Belt — Soft Surface

The 3-Ply White Felt Bakery Conveyor Belt suits food and baking spots where careful touch matters. Its gentle felt top guards soft items like dough, baked treats, and fresh pastries as they move along.

Under that top, a three-layer backed setup gives firm backing without turning the belt rigid. And this blend allows even running while holding clean rules typical in food plants.

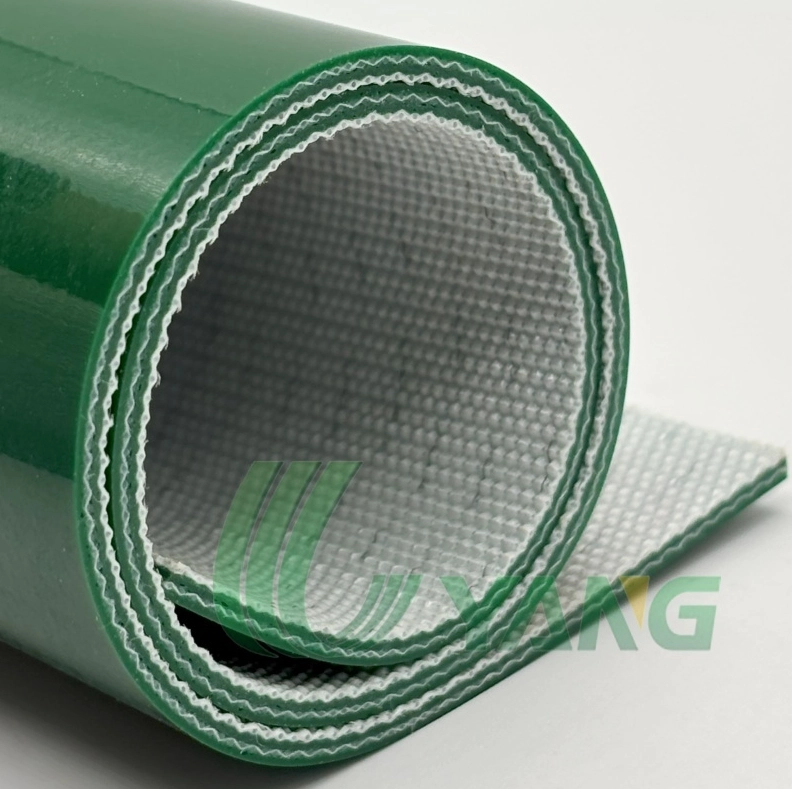

Green Matte PVC Conveyor Belt

The Green Matte PVC Conveyor Belt targets hold and guidance. Its dull top boosts rub, so it fits sloped moves or spots where items need to stay put as they shift.

This belt sees common use in packing lines and basic industry sorting systems. And the dull finish comes from set top handling in production, which keeps even feel over the belt’s span.

Green Smooth PVC Conveyor Belt

The Green Smooth PVC Conveyor Belt gives low drag and simple wipe-down. Its even top aids quick item flow, and it works well where pace and spotless state count.

Even tops demand sharp pressing to skip top bumps or depth shifts. UYANG BELTING’s output management ensures flat tops that cut rub without harming lasting strength.

What Applications Benefit Most From UYANG PVC Conveyor Belts?

Production skill proves its true worth when belts enter routine work. UYANG BELTING’s PVC conveyor belts aim to meet needs in key use fields. And knowing where each belt shines best guides buyers to smarter picks.

Food Processing And Packaging Lines

Food handling calls for clean tops, steady shifts, and stuff that takes repeated washes. Felt and even PVC belts find wide use in baking shops, snack making, and packing areas.

UYANG BELTING’s food-safe builds aid steady item flow, and they match clean standards seen in world markets.

Light Industrial Assembly And Logistics

In build lines and shipping hubs, belts face cycle after cycle without pull or top harm. Dull and even PVC belts often get picked for their fair hold and output balance. So, firm path-keeping and less stop time stand as main gains in these spots, where tiny holds-up add fast.

Custom Projects And OEM Integrations

Original makers and system fitters often seek belts that match set sizes or output needs. UYANG BELTING aids custom spans, depths, and top choices, which eases fitting without redoing full setups. And this bend lets clients grow work while keeping steady belt action over varied tasks.

Conclusion

China’s top spot in PVC conveyor belt production rests on process oversight, material skill, and growing output setups. Tough belts stem from steady production steps, not quick paths.

UYANG BELTING shows how thoughtful material choice, ordered layering, and firm checks turn into belts that work well in food, shipping, and basic industry tasks. For buyers seeking past outer details, grasping the production method gives a sharper way to lasting worth and work steadiness.

FAQ

Q1: What makes PVC conveyor belts suitable for food processing applications?

A: PVC belts offer smooth or soft surfaces that are easy to clean and resistant to moisture and common food residues, making them suitable for bakery and packaging environments.

Q2: How does belt surface texture affect performance?

A: Surface texture influences grip and movement control. Matte surfaces provide better friction, while smooth surfaces allow faster, low-resistance transport.

Q3: Can PVC conveyor belts be customized for specific systems?

A: Yes. Manufacturers like UYANG BELTING support customization in width, length, thickness, and surface type to match different conveyor designs and operating conditions.