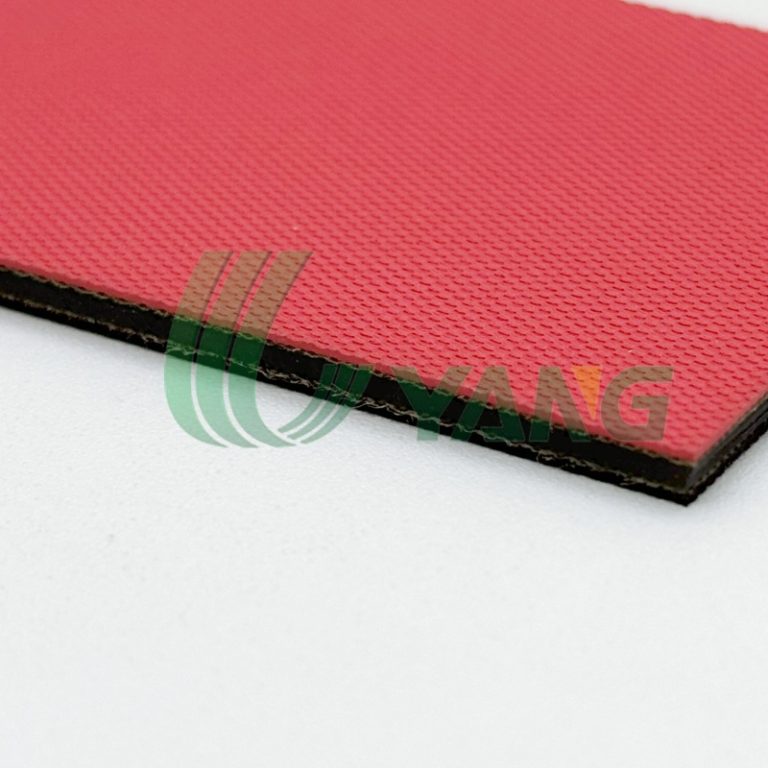

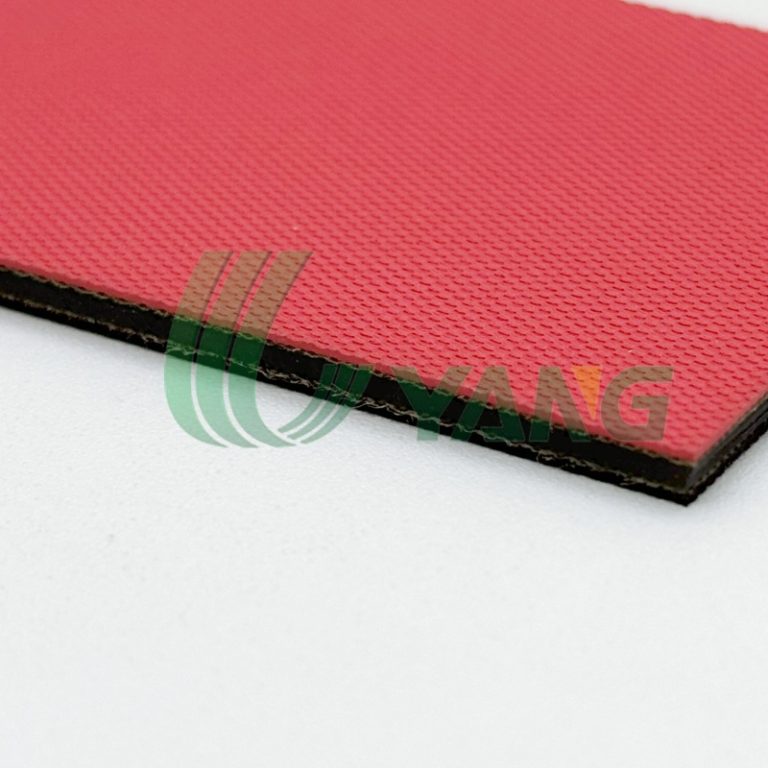

The UYANG XNBR Antistatic Transmission Belt is an industrial flat belt engineered for stable power transmission in environments where static control, oil resistance, and durability are required.

Manufactured with XNBR (Carboxylated Nitrile Rubber), this belt provides excellent antistatic performance, wear resistance, and mechanical strength, making it suitable for continuous operation in demanding industrial applications.

The UYANG XNBR Antistatic Transmission Belt is an industrial flat belt engineered for stable power transmission in environments where static control, oil resistance, and durability are required.

Manufactured with XNBR (Carboxylated Nitrile Rubber), this belt provides excellent antistatic performance, wear resistance, and mechanical strength, making it suitable for continuous operation in demanding industrial applications.

Power transmission systems

Packaging and printing machinery

Electronics and assembly lines

Industrial conveyors with antistatic requirements

Machinery operating in oil-exposed environments

XNBR Rubber Construction

Offers superior wear resistance, high tensile strength, and long service life.

Antistatic Performance

Effectively dissipates static electricity, reducing dust attraction and improving operational safety.

Excellent Oil & Chemical Resistance

Suitable for environments exposed to oils, greases, and industrial chemicals.

Stable Power Transmission

Ensures consistent friction and minimal slip during continuous operation.

Industrial-Grade Durability

Designed for demanding transmission and conveying systems.

| Item | Specification |

|---|---|

| Belt Type | XNBR Antistatic Transmission Belt |

| Surface Material | XNBR (Carboxylated Nitrile Rubber) |

| Antistatic Property | Yes |

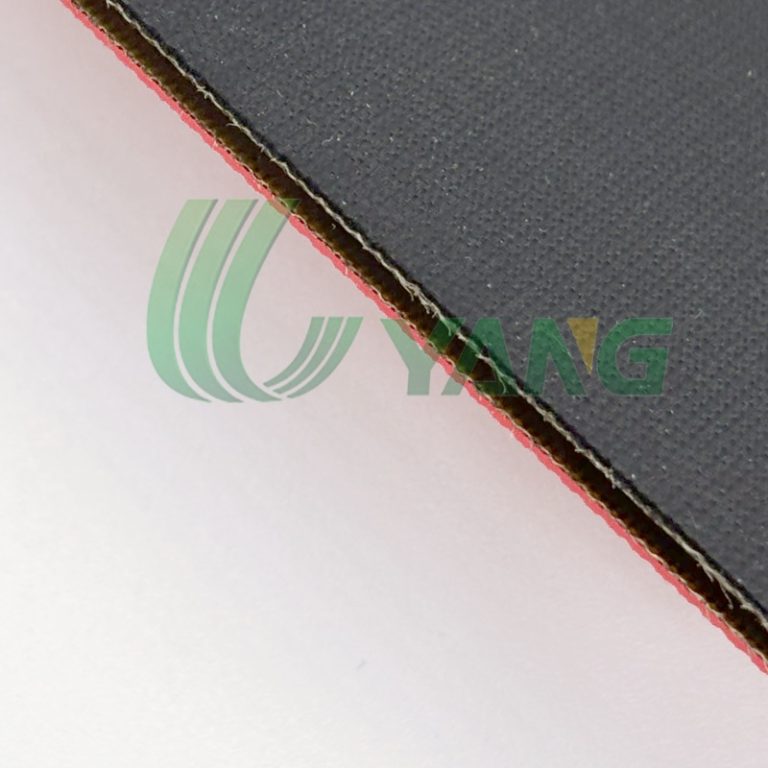

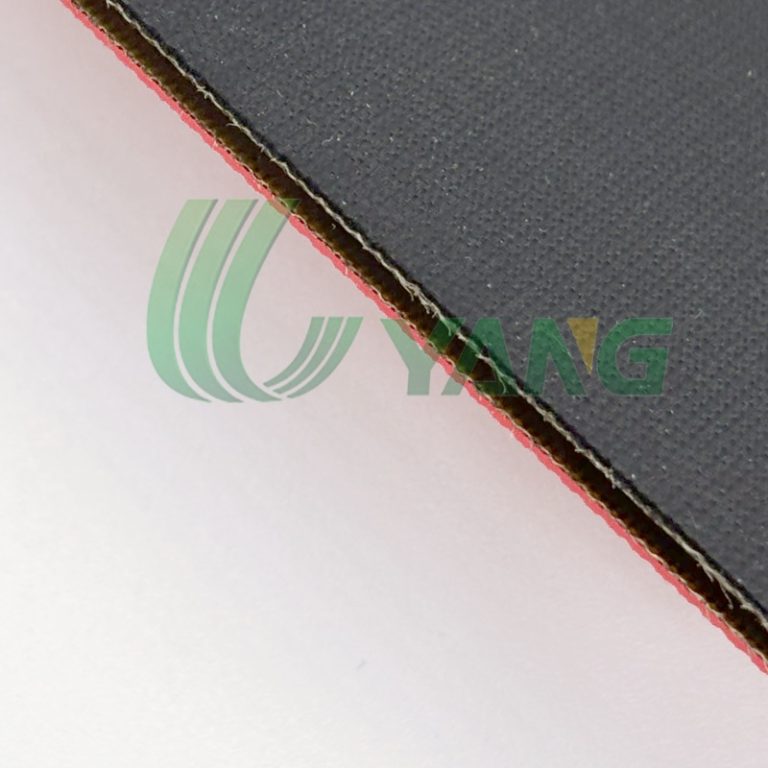

| Structure | Reinforced flat belt construction |

| Thickness | Customized (e.g. 1.0 – 8.0 mm) |

| Belt Width | 500mm |

| Elongation | Low |

| Oil Resistance | Excellent |

| Application Type | Power transmission & conveying |

| Endless Joint | Available upon request |

| Customization | Width, thickness, length |

Specifications may vary depending on belt construction and dimensions. Please contact us for detailed technical data.

| ITEM NO. | THICK

NESS |

TRAC

TION |

CONVE

RYING SIDE |

CONVE

RYING SIDE |

FRICTION SIDE | FRICTION SIDE | JOINING METHOD | ANTI

STATIC |

TEMPER

ATURE |

MAX WIDTH |

| (MM) | LAYER | COLOR | MATERIAL | COLOR | MATERIAL | (OC) | (MM) | |||

| UYL-4.0 | 4.0 | PA | Grey | LEATHER | Grey | LEATHER | Skived joint | Y | -20~80 | 500 |

| UYL-5.0 | 5.5 | PA | Grey | LEATHER | Grey | LEATHER | Skived joint | N | -20~80 | 500 |

| UYL-6.0 | 7.0 | PA | Grey | LEATHER | Grey | LEATHER | Skived joint | N | -20~80 | 500 |

| UYL-8.0 | 9.0 | PA | Grey | LEATHER | Grey | LEATHER | Skived joint | N | -20~80 | 500 |

| UY-R-30N8 | 3.0 | PA | Red | FABRIC | Grey | LEATHER | Skived joint | N | -20~80 | 500 |

| UY-G-40N12 | 4.0 | PA | Green | NBR | Grey | LEATHER | Skived joint | N | -20~80 | 500 |

| UYCL-40K | 4.0 | PA | Black | PA/CO | Grey | LEATHER | Skived joint | N | -20~80 | 500 |

| UYCL-50K | 5.0 | PA | Black | PA/CO | Grey | LEATHER | Skived joint | N | -20~80 | 500 |

| UYCL-60K | 6.0 | PA | Black | PA/CO | Grey | LEATHER | Skived joint | N | -20~80 | 500 |

Widths & Lengths — Available in customized widths and lengths based on customer requirements.

Endless Joint / Splicing — Optional manufacturing services to meet installation needs.

Application Support — Contact us with your machine parameters for belt selection assistance.

Reliable delivery schedules and warehousing support.

Competitive pricing to maximize overall value.

Diverse options to cater to all market segments.

Flexible MOQ Support with all types of goods;

Personalized logo customization on the products

Provide online technical support for all product usage and installation processes

Quick first response to all inquiry and questions

Provide quality images, Video to enhance sales revenue

Efficient production and ship within 15 days at the fastest.

Generally it is 10-15 days, if peak season, it will be about 15-20 day safter receiving the deposit

1. Confirmed Specification: thickness,color, plies,characteristic, and industry;

2. Samples sending: we send samples for you check.or you send us samples if customized belt.

3. Confirm Order: Signing sales contract after samples confirmed.

4. Deposit: 30% deposit before mass production.

5. Production arranged : we will process the production.

6. Remaining payment: after inspection, balance before shipment.

7. Shipping: we will ship the goods to destination port.

8. Confirm bill of loading/commercial invoice/packing list/certificate of origin;