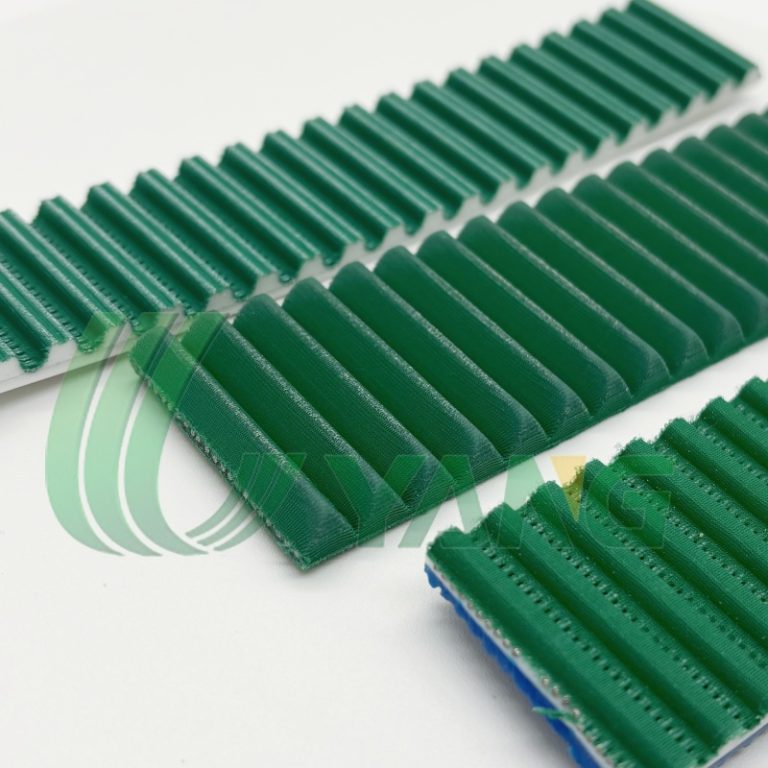

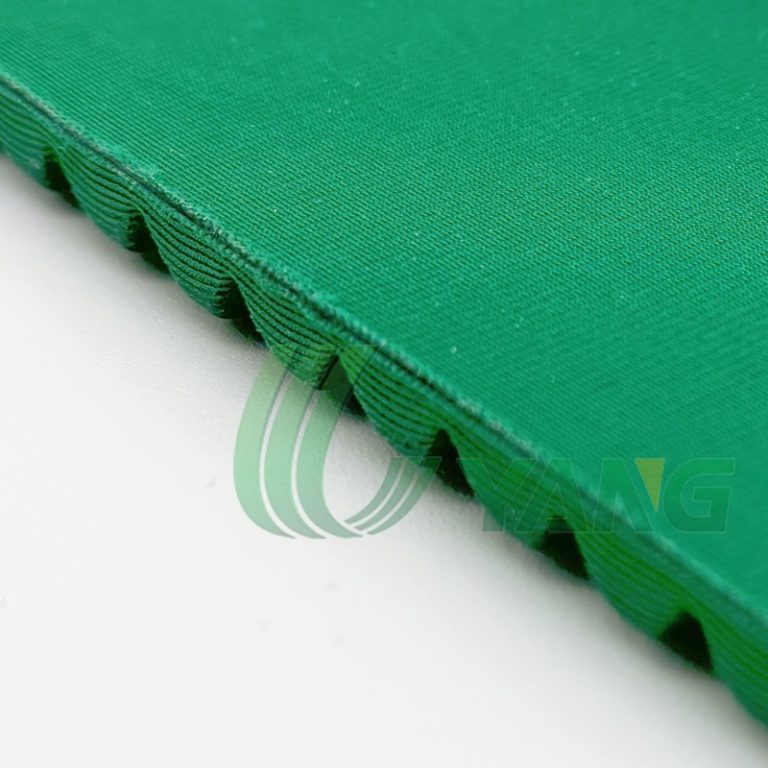

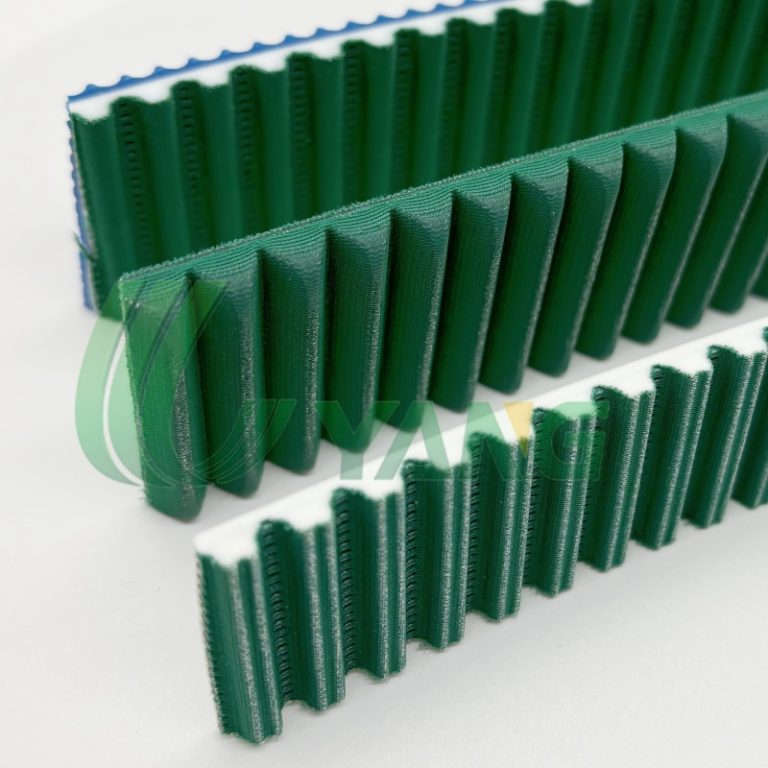

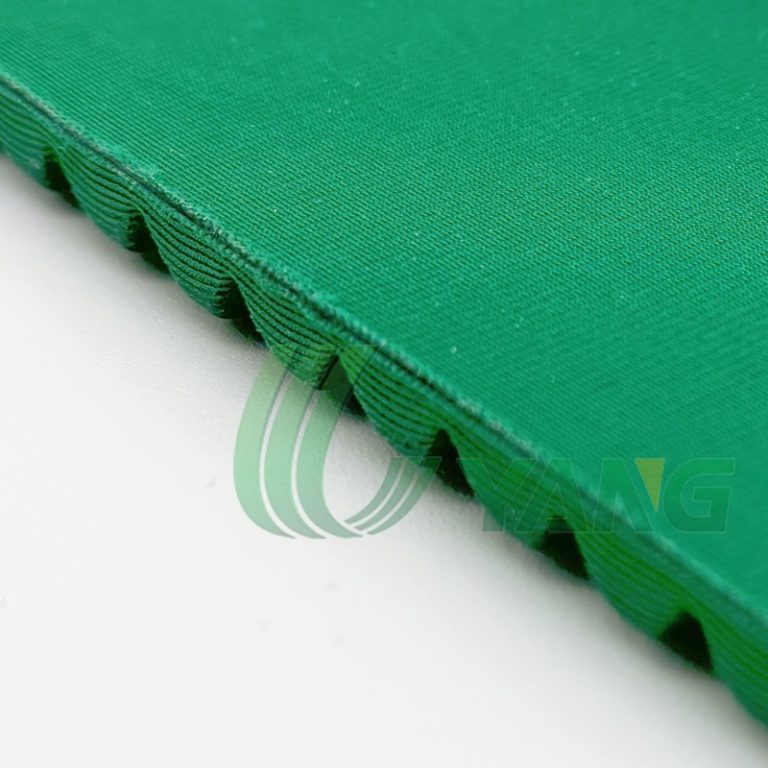

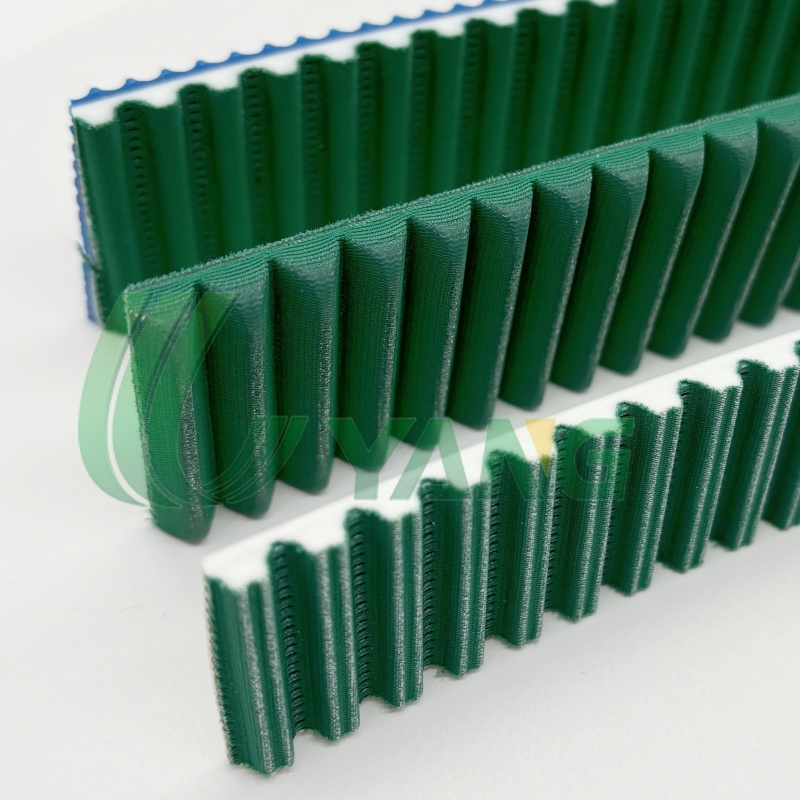

UYANG PU Timing Belt with PAZ/PAR is an enhanced thermoplastic polyurethane synchronous belt featuring a durable fabric overlay on the tooth side (PAZ / NFT) and/or the back side (PAR / NFB). These fabric reinforcements are applied during manufacture to improve key performance characteristics beyond those of a standard PU timing belt.

UYANG PU Timing Belt with PAZ/PAR is an enhanced thermoplastic polyurethane synchronous belt featuring a durable fabric overlay on the tooth side (PAZ / NFT) and/or the back side (PAR / NFB). These fabric reinforcements are applied during manufacture to improve key performance characteristics beyond those of a standard PU timing belt.

Typical Use Cases

Precision motion control systems

High-speed automated machinery

Conveyor and accumulation applications

Packaging, printing, and material handling equipment

Drives with frequent start/stop or reverse cycles

Key Features

🔹 PAZ/NFT (Tooth Side Fabric)

Improved Wear Resistance: The polyamide (nylon) cloth on the tooth surface significantly reduces abrasion between belt teeth and pulley during repeated meshing, extending service life.

Lower Noise & Vibration: The fabric layer acts as a cushion between mating surfaces, reducing noise and vibration in high-speed or precision drives.

Cleaner Operation: PAZ cloth provides anti-dust and anti-oil properties, inhibiting contaminant adhesion on the tooth surface and supporting stable performance.

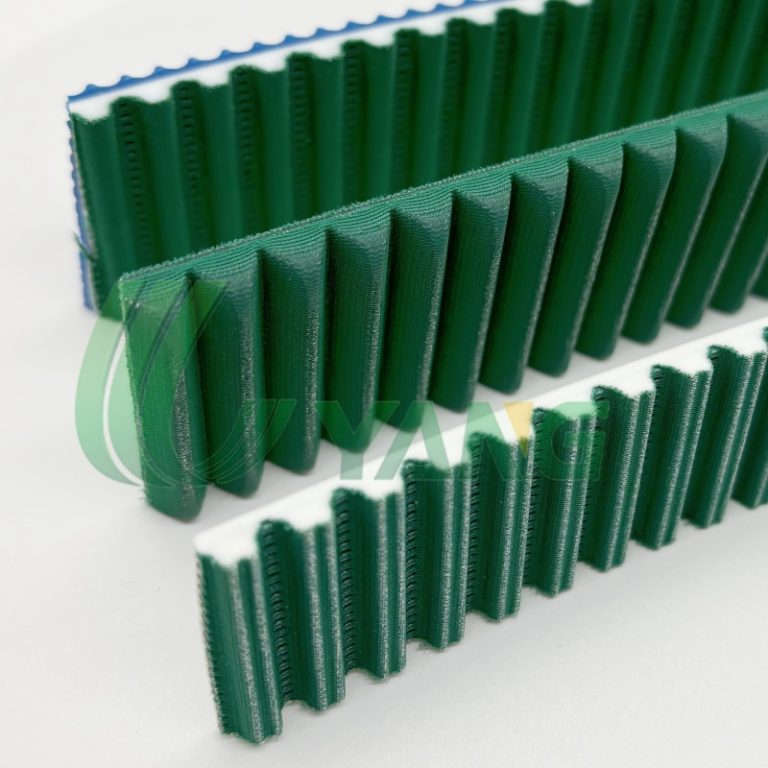

🔹 PAR /NFB (Back Side Fabric)

Reduced Friction & Thermal Load: A low-friction fabric on the belt’s backside lowers heat build-up under heavy load or high-speed operation, mitigating thermal aging of the PU material.

Enhanced Durability in Reverse/Bidirectional Motion: PAR backside reinforcement distributes stress more evenly under bidirectional drives or high tension, reducing wear and cracking.

Extended Belt Life: Reduced friction and mechanical stress contribute to longer operational life compared to uncoated belts.

🔹 Combined PAZ + PAR

Balanced Performance: Combining fabric on both the tooth side and back side yields quieter, smoother transmission with low friction.

Robust for Demanding Systems: Ideal for heavy-load, high-precision automation, packaging, printing, and conveying equipment where long life and reliability are required.

Lower Maintenance Cost: Extended durability reduces the frequency of belt replacement and associated downtime.

Typical Use Cases

Precision motion control systems

High-speed automated machinery

Conveyor and accumulation applications

Packaging, printing, and material handling equipment

Drives with frequent start/stop or reverse cycles

Technical Notes

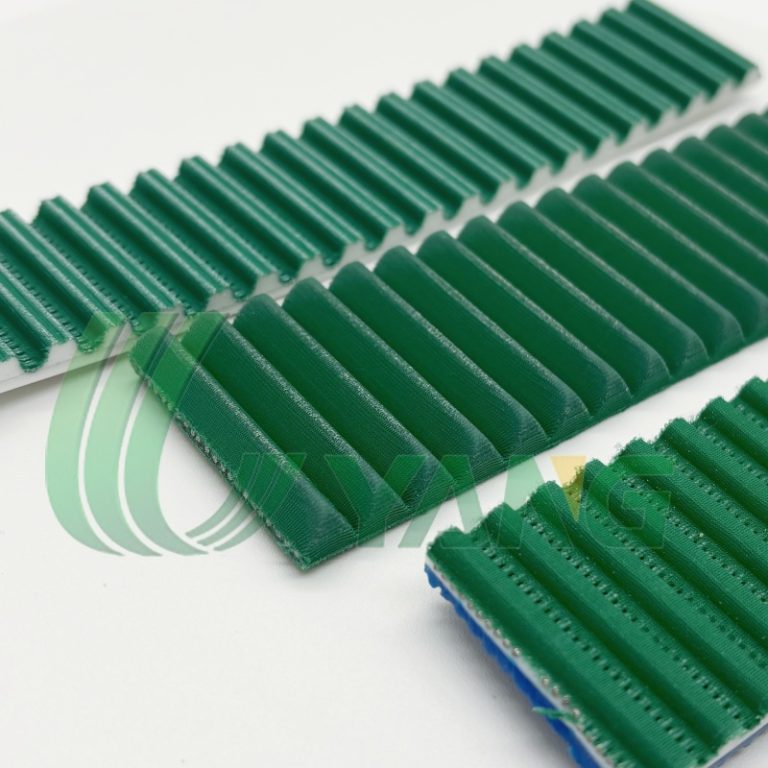

PAZ/PAR coatings can be in green or black polyamide fabric depending on application requirements.

Fabric coverings are compatible with belts reinforced with steel, Kevlar, or stainless-steel cords and across common PU belt profiles.

| Type | Fabric Position | Key Characteristics | Typical Applications |

|---|---|---|---|

| Standard PU Timing Belt | None | Basic power transmission, cost-effective | General machinery, standard drives |

| PU Timing Belt with PAZ | Tooth side (PAZ / NFT) | Quieter operation, reduced tooth wear, precise meshing | Automation equipment, packaging machines |

| PU Timing Belt with PAR | Back side (PAR / NFB) | Low backside friction, improved durability against rollers and idlers | Conveyors, guide rollers, backside running systems |

| PU Timing Belt with PAZ + PAR | Tooth side + Back side | Low noise, low friction, extended service life | High-load systems, high-precision & advanced machinery |

PAZ is recommended when noise reduction, smooth meshing, and positioning accuracy are critical.

PAR is preferred when the belt runs against rollers or idlers on the backside.

PAZ + PAR offers the most balanced performance for long-life, high-duty, and high-value equipment.

Reliable delivery schedules and warehousing support.

Competitive pricing to maximize overall value.

Diverse options to cater to all market segments.

Flexible MOQ Support with all types of goods;

Personalized logo customization on the products

Provide online technical support for all product usage and installation processes

Quick first response to all inquiry and questions

Provide quality images, Video to enhance sales revenue

Efficient production and ship within 15 days at the fastest.

Generally it is 10-15 days, if peak season, it will be about 15-20 day safter receiving the deposit

1. Confirmed Specification: thickness,color, plies,characteristic, and industry;

2. Samples sending: we send samples for you check.or you send us samples if customized belt.

3. Confirm Order: Signing sales contract after samples confirmed.

4. Deposit: 30% deposit before mass production.

5. Production arranged : we will process the production.

6. Remaining payment: after inspection, balance before shipment.

7. Shipping: we will ship the goods to destination port.

8. Confirm bill of loading/commercial invoice/packing list/certificate of origin;