The UYANG AT10K13 Polyurethane Timing Belt is a high-performance special profile timing belt developed for precision positioning, repetitive indexing, and function-driven synchronous conveying systems.

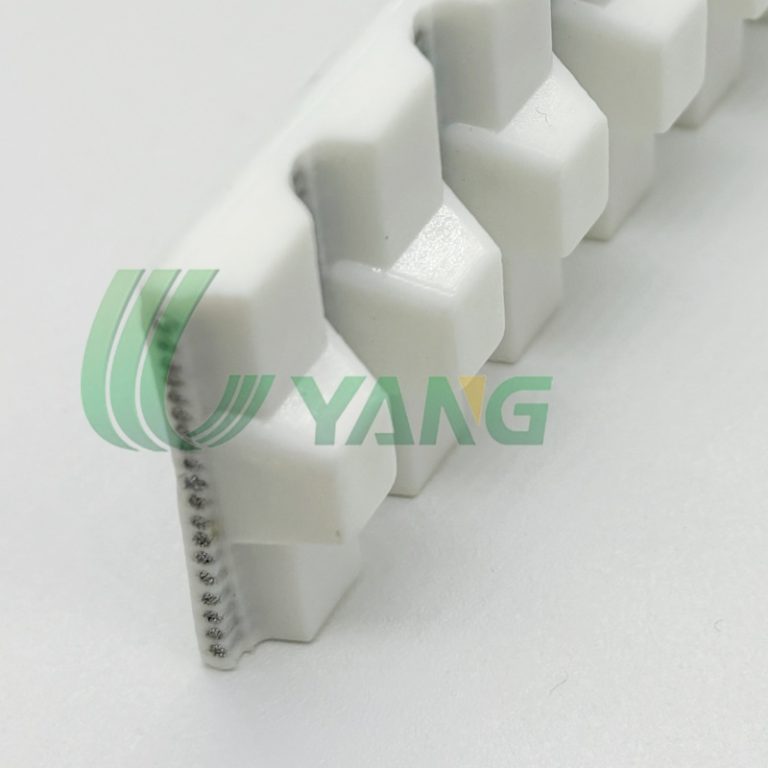

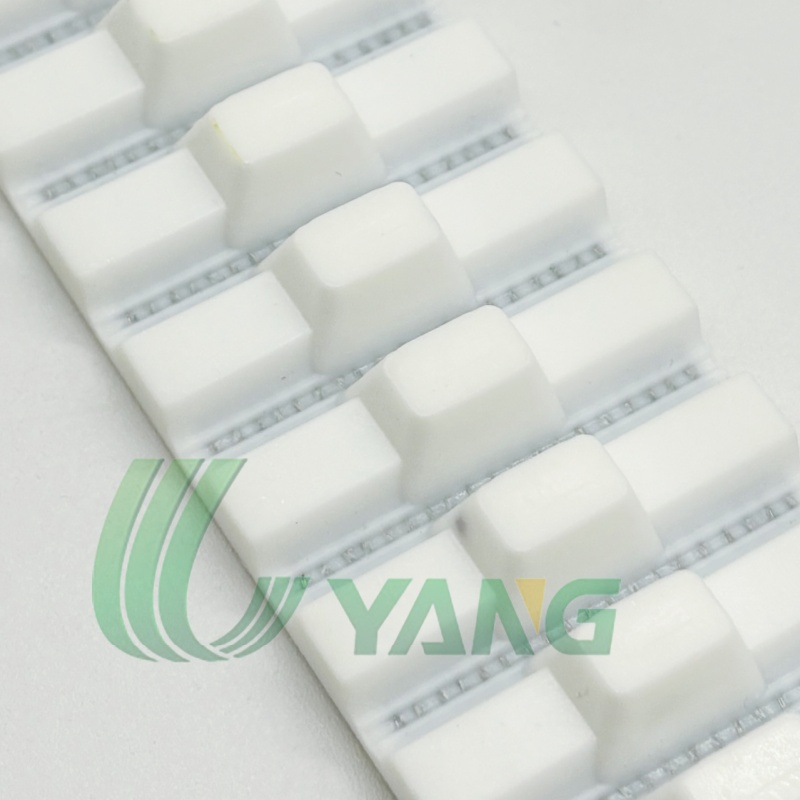

Compared with standard AT10 and AT10K10 belts, the K13 tooth geometry provides maximum tooth engagement and enhanced load stability, significantly reducing micro-slip and deformation under cyclic loads.

Manufactured from wear-resistant TPU and reinforced with low-elongation tensile cords, UYANG AT10K13 timing belts deliver exceptional positioning accuracy, long service life, and stable synchronization in demanding industrial applications.

The UYANG AT10K13 Polyurethane Timing Belt is a high-performance special profile timing belt developed for precision positioning, repetitive indexing, and function-driven synchronous conveying systems.

Compared with standard AT10 and AT10K10 belts, the K13 tooth geometry provides maximum tooth engagement and enhanced load stability, significantly reducing micro-slip and deformation under cyclic loads.

Manufactured from wear-resistant TPU and reinforced with low-elongation tensile cords, UYANG AT10K13 timing belts deliver exceptional positioning accuracy, long service life, and stable synchronization in demanding industrial applications.

Brand: UYANG BELTING

Model: AT10K13 PU Timing Belt

Pitch: 10 mm

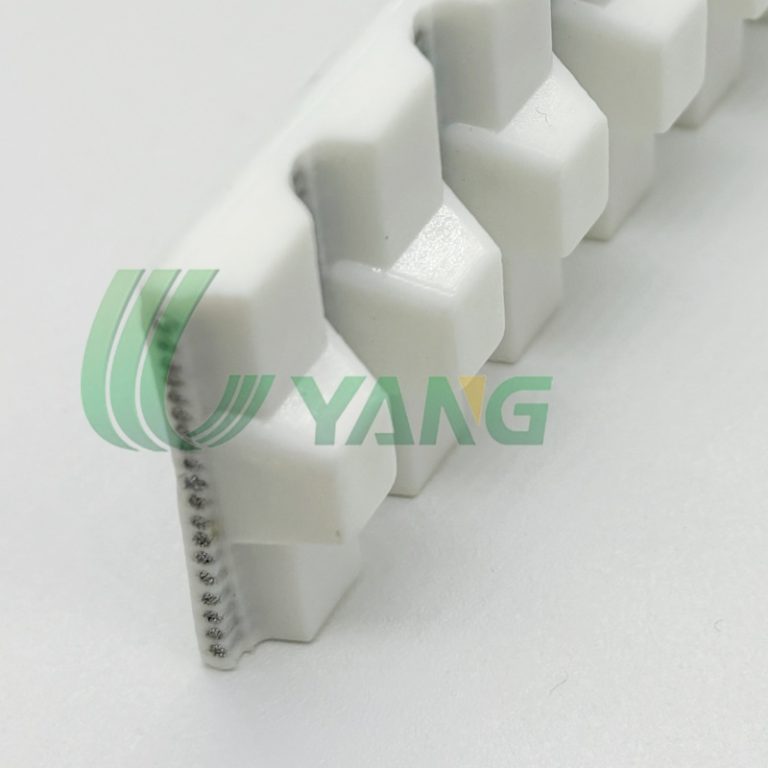

Tooth Profile: AT10K13

Material: Thermoplastic Polyurethane (TPU)

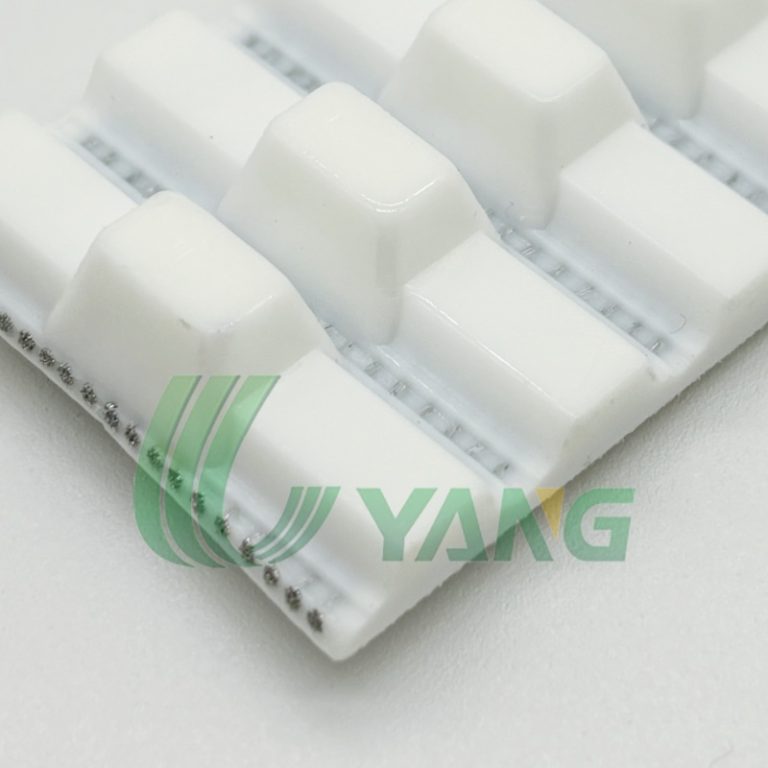

Tension Member: Steel Cord / Aramid Cord (optional)

| Item | Value |

|---|---|

| Tooth Profile | AT10K13 |

| Pitch | 10 mm |

| Standard Widths | 25 / 32 / 50 mm (custom available) |

| Belt Construction | TPU body + steel / aramid cords |

| Operating Temperature | −20 °C to +80 °C |

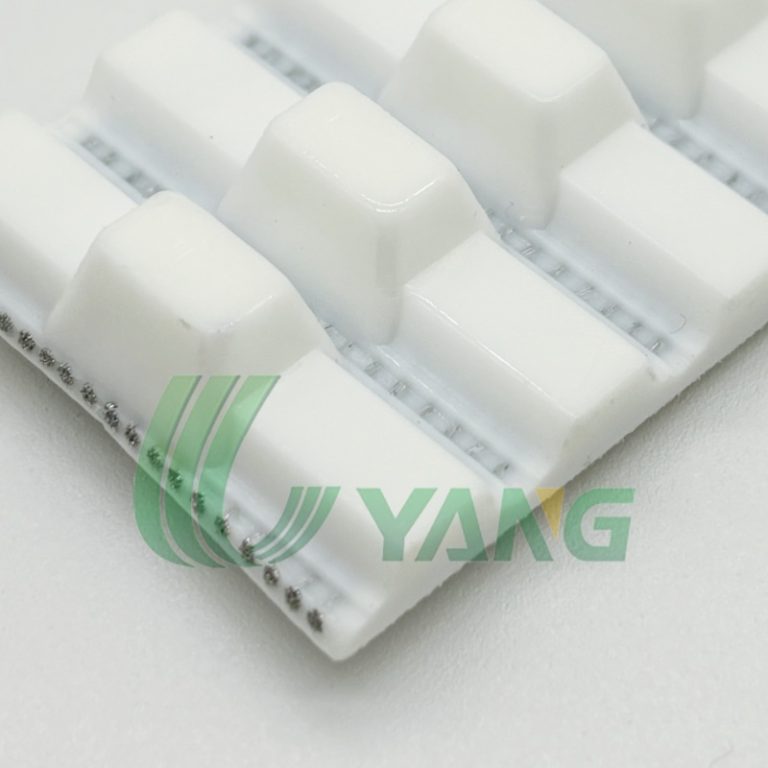

| Color | White / Natural (custom colors available) |

| Manufacturing Type | Open End / Welded Endless / Truly Endless |

Dimensions and constructions can be customized according to application requirements.

AT10K13 timing belts are commonly supplied with advanced functional configurations:

Cleats / Flights

Precisely positioned cleats for indexing and separation applications.

PAZ / PAR / PAZ + PAR

Reduced friction, quieter operation, improved durability and service life.

PU or High-Friction Backings

For controlled conveying or inclined transport.

Machined Belt Backs

Grooves, slots, holes, or contours for custom OEM requirements.

Precision indexing conveyors

Pick-and-place automation systems

Packaging and sorting lines with positioning control

Automated assembly equipment

OEM machinery requiring high repeatability

AT10K13 belts are typically selected when standard AT10 or AT10K10 belts cannot meet positioning accuracy or stability requirements.

| Feature | AT10 | AT10K10 | AT10K13 |

|---|---|---|---|

| Tooth Engagement | High | Enhanced | Maximum |

| Positioning Accuracy | High | High | Very High |

| Customization Level | Low | High | Very High |

| Typical Use | Transmission & conveying | Synchronous conveying | Precision indexing |

Choose AT10K13 when precision, repeatability, and load stability are critical to system performance.

Designed for precision-driven industrial applications

Stable pitch accuracy and low elongation

Strong capability for customized OEM solutions

Export-oriented manufacturing standards

UYANG BELTING focuses on engineering-grade timing belt solutions, not generic catalog products.

For fast quotation and technical support, please provide:

Required belt width and length

Endless type (open / welded / truly endless)

Cleat type, size, and spacing (if required)

Backing or surface requirements

Application details (load, speed, cycle frequency)

Reliable delivery schedules and warehousing support.

Competitive pricing to maximize overall value.

Diverse options to cater to all market segments.

Flexible MOQ Support with all types of goods;

Personalized logo customization on the products

Provide online technical support for all product usage and installation processes

Quick first response to all inquiry and questions

Provide quality images, Video to enhance sales revenue

Efficient production and ship within 15 days at the fastest.

Generally it is 10-15 days, if peak season, it will be about 15-20 day safter receiving the deposit

1. Confirmed Specification: thickness,color, plies,characteristic, and industry;

2. Samples sending: we send samples for you check.or you send us samples if customized belt.

3. Confirm Order: Signing sales contract after samples confirmed.

4. Deposit: 30% deposit before mass production.

5. Production arranged : we will process the production.

6. Remaining payment: after inspection, balance before shipment.

7. Shipping: we will ship the goods to destination port.

8. Confirm bill of loading/commercial invoice/packing list/certificate of origin;