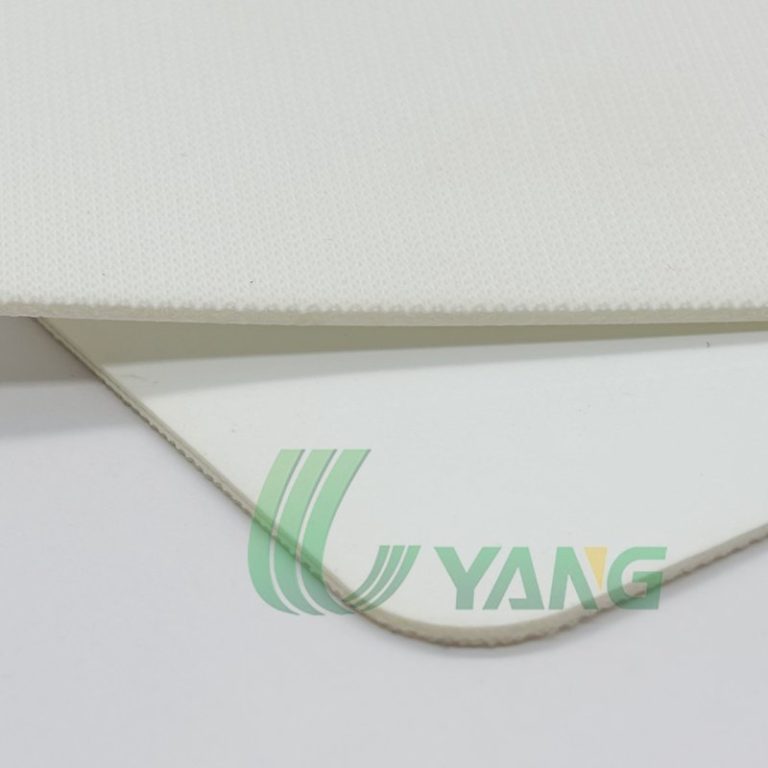

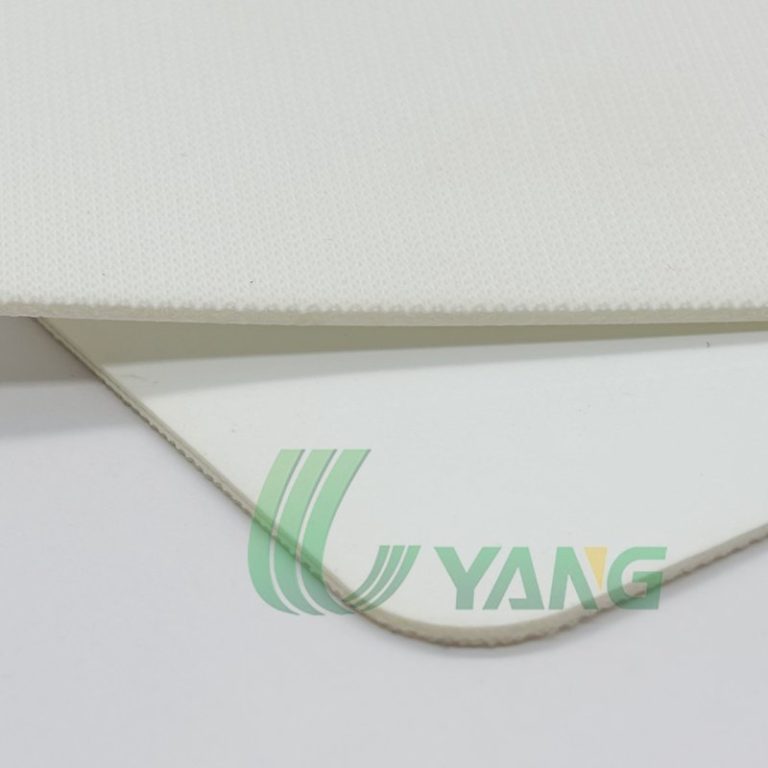

The UYANG 2.5mm White PU Smooth Conveyor Belt is a medium-thickness thermoplastic polyurethane belt designed for applications requiring higher durability, improved load capacity, and hygienic performance.

With a smooth top surface and reinforced fabric carcass, this belt provides reliable conveying stability in food processing and light-to-medium industrial environments.

Compared with thinner PU belts, the 2.5mm structure offers improved wear resistance and longer service life under continuous operation.

The UYANG 2.5mm White PU Smooth Conveyor Belt is a medium-thickness thermoplastic polyurethane belt designed for applications requiring higher durability, improved load capacity, and hygienic performance.

With a smooth top surface and reinforced fabric carcass, this belt provides reliable conveying stability in food processing and light-to-medium industrial environments.

Compared with thinner PU belts, the 2.5mm structure offers improved wear resistance and longer service life under continuous operation.

Top Cover: White PU (Smooth surface)

Carcass: Multi-ply polyester fabric reinforcement

Bottom Surface: Fabric backing

Total Thickness: 2.5 mm

Surface Type: Smooth matte finish

Operating Temperature: -20°C to +80°C

Food Compliance: FDA / EU available upon request

The thicker 2.5mm construction:

Improves abrasion resistance

Extends belt lifetime

Handles higher load compared with 0.8mm–1.0mm belts

The smooth white PU top:

Easy to clean

Suitable for direct food contact

Resistant to oils and fats

Multi-layer fabric reinforcement ensures:

Controlled elongation

Dimensional stability

Reliable tracking performance

Suitable for:

Food processing lines

Meat & poultry conveying

Dairy & bakery transport

Medium-duty packaging systems

Food slicing & processing conveyors

Packaging and sealing lines

Transfer conveyors with moderate load

Industrial assembly lines

OEM conveyor systems

In medium-duty conveying systems, balance is critical.

A 2.5mm PU belt offers:

Greater wear resistance than ultra-thin belts

Better load distribution

Reduced risk of premature cracking

Longer replacement intervals

It is a practical choice for customers seeking durability without moving to heavy rubber belts.

Endless fabrication (finger joint / stepped joint)

Sidewalls and cleats

Perforation

Edge sealing

Custom width and length

To recommend the correct belt specification, we confirm:

Product weight and dimensions

Conveyor speed

Minimum pulley diameter

Environmental conditions

Required compliance standards

Correct belt selection improves system reliability and reduces long-term operating costs.

Reliable delivery schedules and warehousing support.

Competitive pricing to maximize overall value.

Diverse options to cater to all market segments.

Flexible MOQ Support with all types of goods;

Personalized logo customization on the products

Provide online technical support for all product usage and installation processes

Quick first response to all inquiry and questions

Provide quality images, Video to enhance sales revenue

Efficient production and ship within 15 days at the fastest.

Generally it is 10-15 days, if peak season, it will be about 15-20 day safter receiving the deposit

1. Confirmed Specification: thickness,color, plies,characteristic, and industry;

2. Samples sending: we send samples for you check.or you send us samples if customized belt.

3. Confirm Order: Signing sales contract after samples confirmed.

4. Deposit: 30% deposit before mass production.

5. Production arranged : we will process the production.

6. Remaining payment: after inspection, balance before shipment.

7. Shipping: we will ship the goods to destination port.

8. Confirm bill of loading/commercial invoice/packing list/certificate of origin;