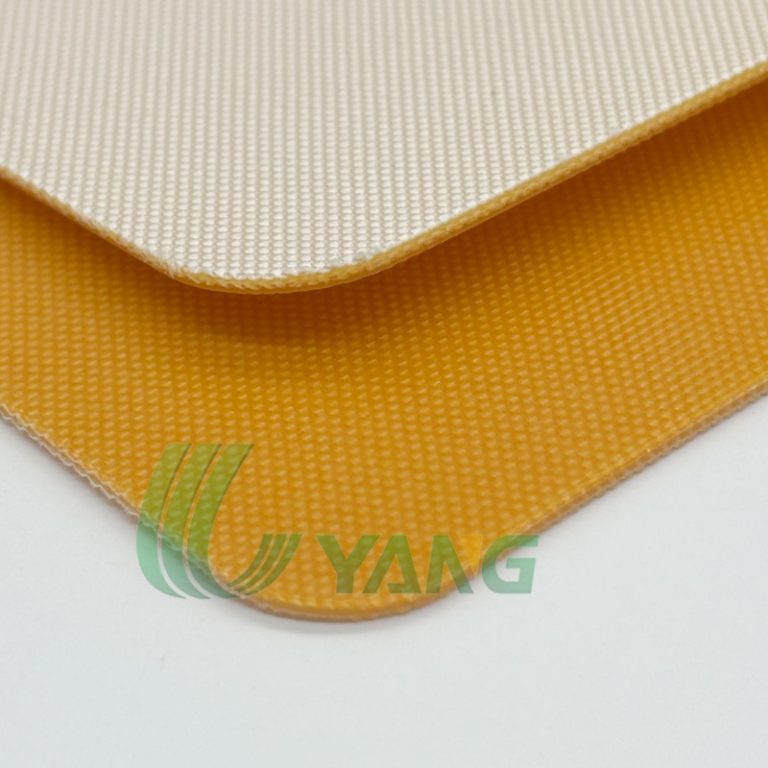

The UYANG 0.8mm Convex Rhombus PU Conveyor Belt is specially designed for chocolate and confectionery processing lines where controlled grip, hygienic performance, and non-stick properties are essential.

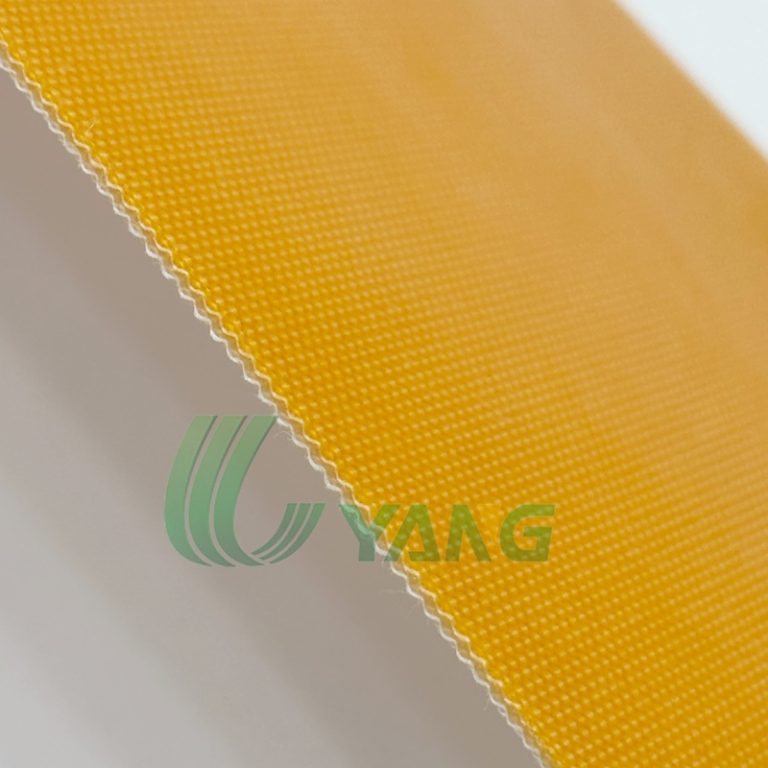

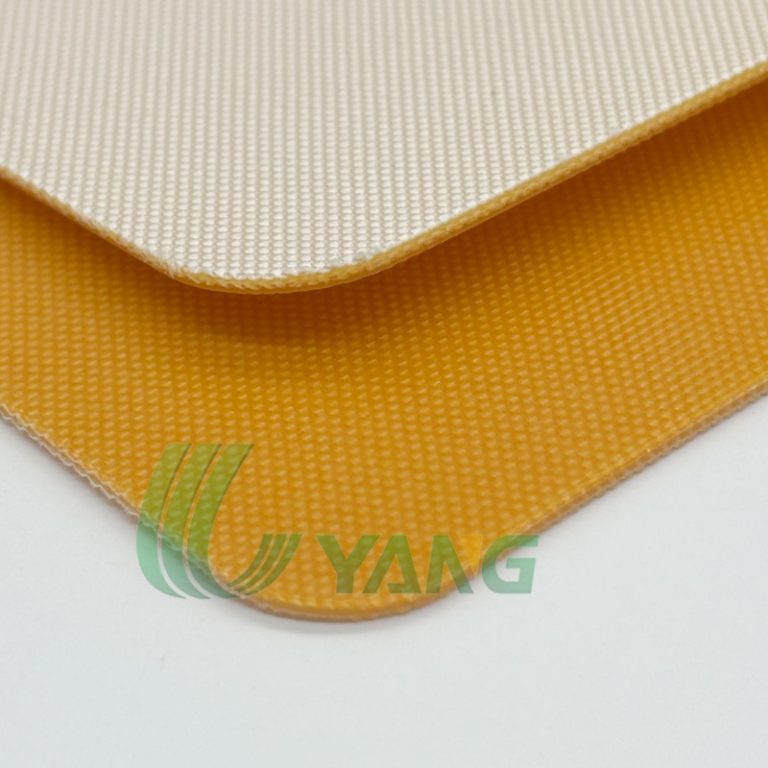

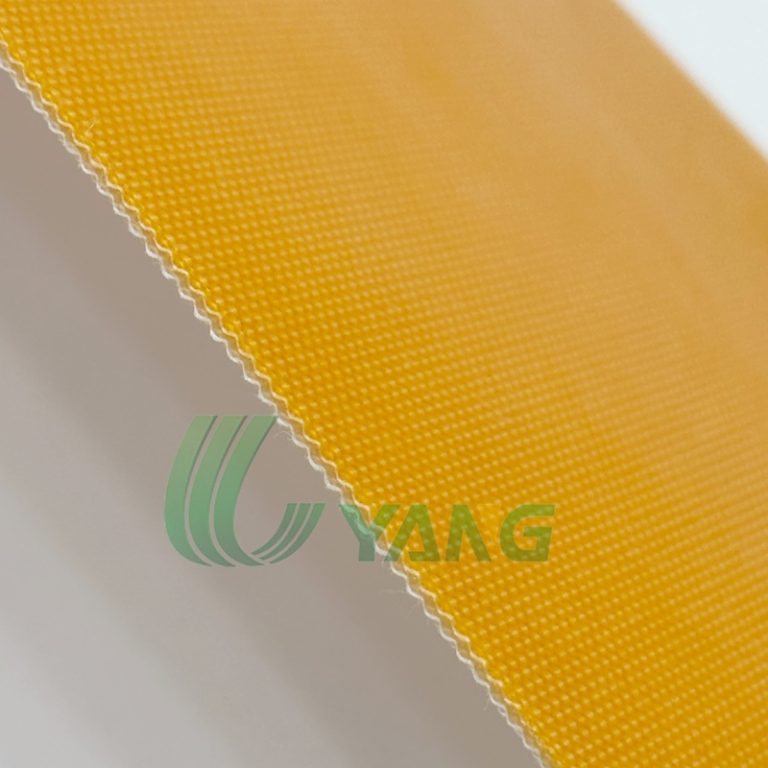

The convex rhombus (raised diamond) surface structure improves friction while minimizing full surface contact, helping reduce product sticking and deformation. With its ultra-thin 0.8mm construction, this belt ensures high flexibility and compatibility with small pulley systems commonly used in chocolate production equipment.

The UYANG 0.8mm Convex Rhombus PU Conveyor Belt is specially designed for chocolate and confectionery processing lines where controlled grip, hygienic performance, and non-stick properties are essential.

The convex rhombus (raised diamond) surface structure improves friction while minimizing full surface contact, helping reduce product sticking and deformation. With its ultra-thin 0.8mm construction, this belt ensures high flexibility and compatibility with small pulley systems commonly used in chocolate production equipment.

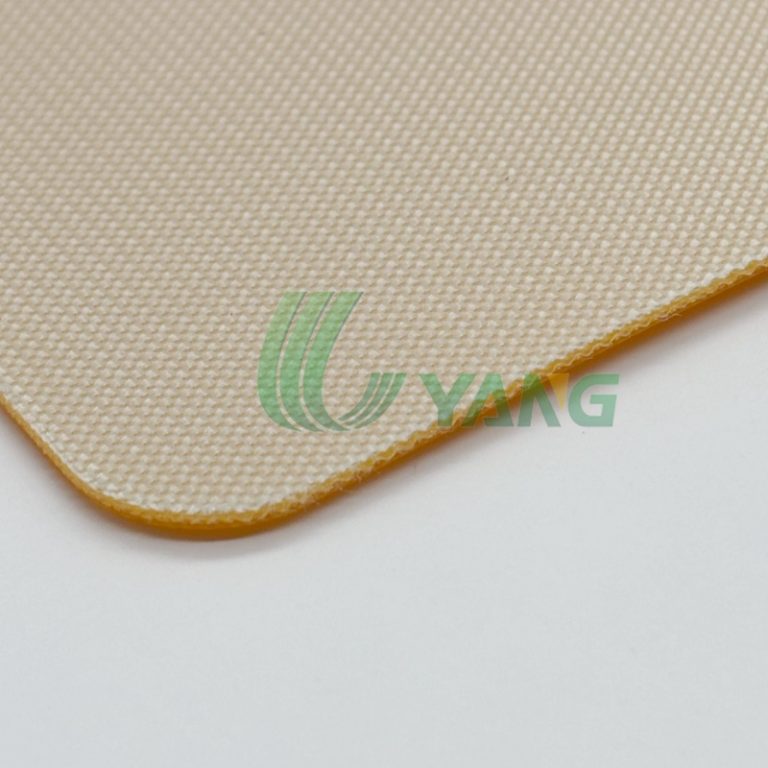

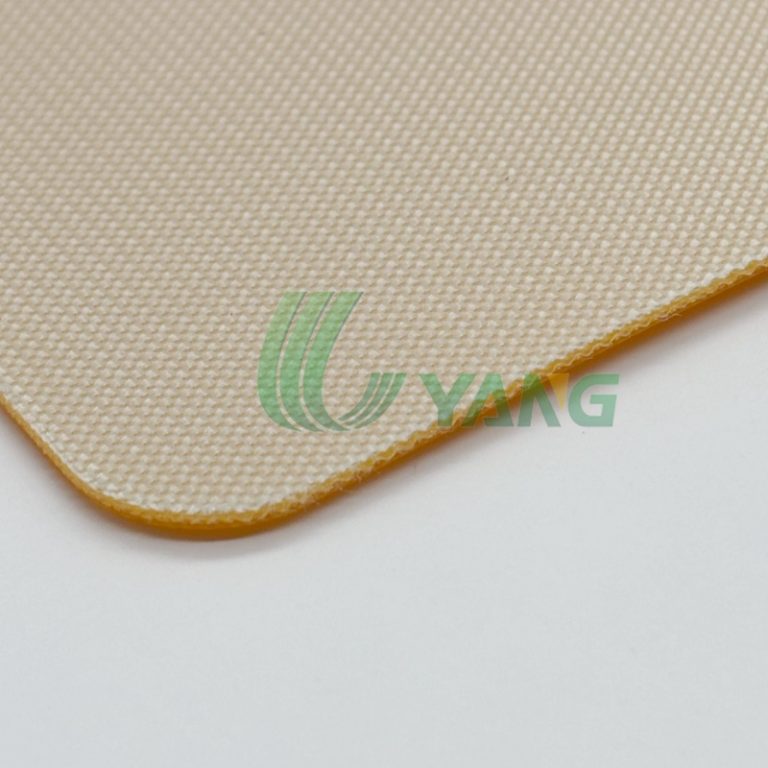

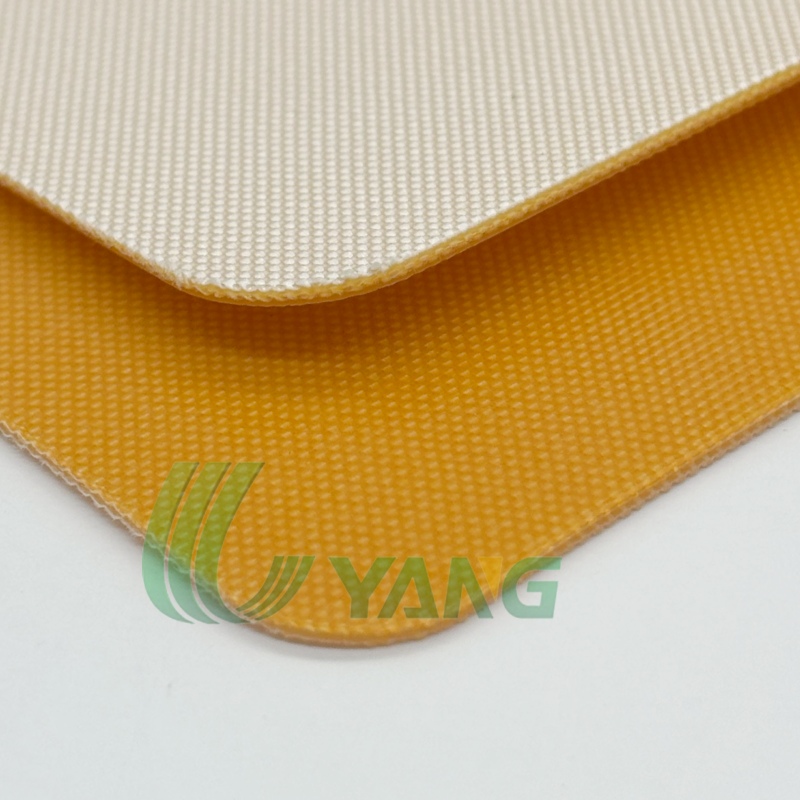

Top Cover: Food-grade PU with convex rhombus embossed pattern

Carcass: Single-ply high-strength polyester fabric

Bottom Surface: Fabric backing

Total Thickness: 0.8 mm

Surface Type: Convex rhombus (raised diamond) texture

Operating Temperature: -20°C to +80°C

Food Compliance: FDA / EU available upon request

The convex rhombus texture:

Reduces full surface contact area

Minimizes chocolate sticking

Improves clean release

Maintains product shape during transfer

This structure is particularly effective for soft, semi-molten, or coated chocolate products.

With only 0.8mm thickness, the belt:

Works efficiently on small pulley diameters

Reduces bending stress

Ensures smooth start-stop motion

Supports compact machine design

Polyurethane surface provides:

Oil and fat resistance

Easy cleaning and hygiene control

Non-absorbent structure

Suitable for direct food contact

Ideal for:

Chocolate enrobing lines

Cooling tunnels

Molding and depositing lines

Biscuit and wafer coating systems

Chocolate products are sensitive to:

Surface adhesion

Shape deformation

Temperature fluctuation

The raised rhombus pattern:

Reduces suction effect

Improves airflow between belt and product

Enhances product stability

Supports clean and efficient transfer

It balances grip and release — critical in confectionery production.

Endless fabrication

Edge sealing

Perforation

Special widths

Integration with cleats or guides

Before recommending a belt specification, we evaluate:

Chocolate type (solid / coated / semi-molten)

Conveyor speed

Cooling tunnel temperature

Minimum pulley diameter

Hygiene requirements

Proper belt selection improves product quality, reduces sticking, and extends belt lifetime.

Reliable delivery schedules and warehousing support.

Competitive pricing to maximize overall value.

Diverse options to cater to all market segments.

Flexible MOQ Support with all types of goods;

Personalized logo customization on the products

Provide online technical support for all product usage and installation processes

Quick first response to all inquiry and questions

Provide quality images, Video to enhance sales revenue

Efficient production and ship within 15 days at the fastest.

Generally it is 10-15 days, if peak season, it will be about 15-20 day safter receiving the deposit

1. Confirmed Specification: thickness,color, plies,characteristic, and industry;

2. Samples sending: we send samples for you check.or you send us samples if customized belt.

3. Confirm Order: Signing sales contract after samples confirmed.

4. Deposit: 30% deposit before mass production.

5. Production arranged : we will process the production.

6. Remaining payment: after inspection, balance before shipment.

7. Shipping: we will ship the goods to destination port.

8. Confirm bill of loading/commercial invoice/packing list/certificate of origin;