Picking a PVC conveyor belt supplier goes beyond just matching a product to your equipment. It means finding a reliable partner who grasps how goods travel along an actual production setup, shift after shift. A belt that seems suitable in specs might still lead to slips, blockages, or quick deterioration when it hits the real operation.

As assembly lines speed up and focus on specific tasks, the conveyor belt’s job has shifted. It no longer serves as a basic carrier. Instead, it influences production pace, item standards, stoppage rates, and even staff protection. For this reason, assessing PVC conveyor belt suppliers demands more than glancing at costs and brochures.

Here are the main elements that count most in choosing a PVC conveyor belt supplier. These include useful cases drawn from genuine factory uses and effective solutions from UYANG BELTING.

Why Does Product Application Fit Matter When Choosing a PVC Conveyor Belt Supplier?

Various substances act quite differently when they start moving. Some glide too freely, while others push back against motion, and certain ones respond poorly to grease or dampness. A supplier who skips in-depth queries about the setup probably won’t suggest the proper belt.

A solid PVC conveyor belt supplier begins with the belt’s intended purpose, rather than its appearance.

Matching Belt Surface to Material Handling Needs

The belt’s top layer texture greatly affects how steadily items stay put while traveling. In boxing setups or sloped carriers, minor slides can cause offsets or item drops.

The Black Crescent Top PVC Conveyor Belt from UYANG BELTING features a raised crescent design that boosts hold without harming goods. This kind of layer suits spots where placement counts, like box moving, sorting setups, and simple factory assembly paths. Rather than cranking up pull on a flat belt, the layer itself aids in directing flow.

Industry-Specific PVC Formulations

Not every PVC belt handles oil, chemicals, or cleaners in the same manner. In food handling, waste sorting, or repair shops, contact with fats or liquids happens often.

The Petrol PVC Conveyor Belt is built for places where oil protection is vital. Its PVC mix cuts down on expansion, top layer failure, and soon cracking. For users with steady runs, this leads to fewer swaps and reduced surprise halts.

Workflow Efficiency and Throughput Stability

In quick-moving lines, drag can turn into a sneaky issue. Too much opposition raises engine strain and part damage.

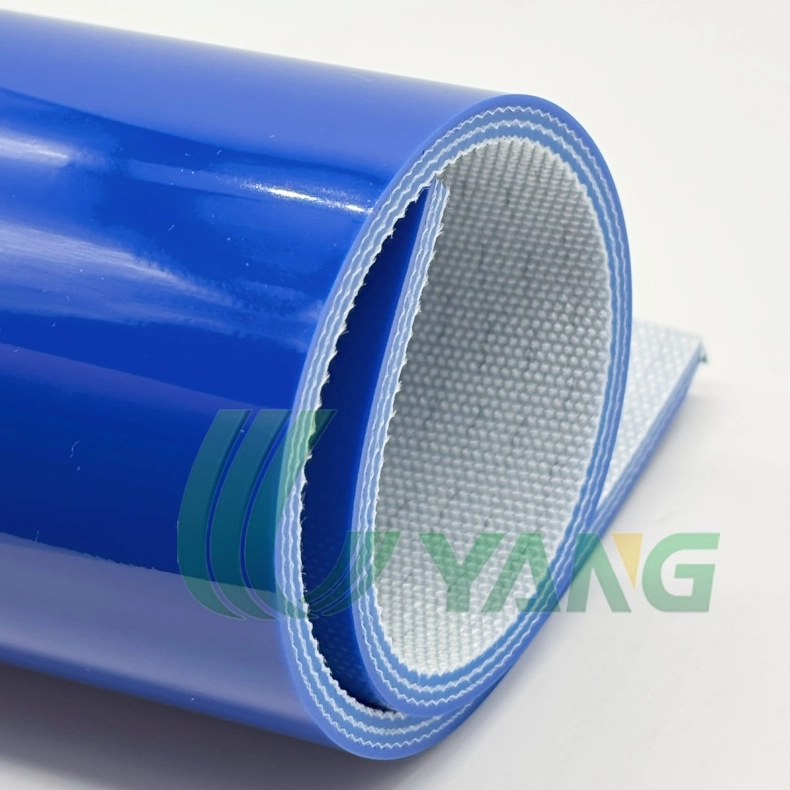

The Blue Glossy PVC Conveyor Belt provides a sleek top that lets items shift with minimal pull. It fits well in boxing, check lines, and easy shipping systems where neat handover and steady stream outweigh hold.

How Important Is Product Range and Customization Capability?

Every production path differs slightly from the next. A supplier stuck with a narrow lineup might suggest a near-fit choice, which usually brings trade-offs down the road.

A broad selection signals that a supplier has dealt with many fields and knows that adaptability fits everyday making.

Availability of Multiple Surface Textures

Even, shiny, coarse, designed, or holding layers each tackle unique challenges. When a supplier provides various finishes, pairing belt action to item action gets simpler.

UYANG BELTING produces PVC conveyor belts with diverse top treatments, from even shiny layers to formed hold designs. This lets buyers tweak carry results without overhauling the whole setup plan.

Width, Thickness, and Length Custom Options

Equipment seldom sticks to basic belt sizes, particularly in tailored or updated paths. Set-measure belts frequently need added joins or frame tweaks.

At UYANG BELTING, belt span, depth, and extent can be tuned to machine plans and run settings. This avoids pushed changes and shortens setup hours on location.

Support for OEM and Non-Standard Designs

OEM buyers and setup builders often require belts for precise arrangements. That covers odd spans, layered builds, or unique side treatments.

UYANG BELTING aids OEM efforts by delivering steady specs and steady standards, which proves key for gear makers aimed at overseas sales.

Can Material Quality and Manufacturing Standards Be Verified?

PVC belts might appear alike at first glance, yet inner build and mix standards vary widely over periods. Quick damage, side unraveling, or top stiffening often stem from substance or method flaws.

Trustworthy suppliers share freely about belt creation.

Consistent PVC Compound Performance

Steady results begin with reliable substances. In belts such as the Petrol PVC Conveyor Belt, the mix is crafted to hold bend while fighting oil uptake. This mix keeps the belt gliding well without turning hard or tacky after extended runs.

Reinforcement and Fabric Stability

The inner cloth layer bears the main burden. Weak backing can spark stretching, path drifts, or patchy damage.

UYANG BELTING employs backed cloth builds suited to belt use, which aids in keeping belt form and path steady even in ongoing work.

Quality Control and Production Traceability

Uniform making counts as much as sound plans. A belt that works fine in one lot but shifts in the next spells ongoing headaches for purchasers.

Through managed making steps and inner standard reviews, UYANG BELTING ensures belt results stay even over lots, a big plus for buyers with several paths or ongoing belt swaps.

What Level of Technical Support Does the Supplier Provide?

A conveyor belt operates within a system that includes rollers, supports, drives, and handlers. Tech help before and after shipment can head off plenty of usual snags.

Suppliers who get this often foster lasting ties.

Pre-Sales Application Evaluation

Prior to making, skilled suppliers inquire about pace, weight, heat, and surroundings. These points shape belt picks more than most buyers grasp.

UYANG BELTING assists buyers in the pick phase, guiding belt choice to match true conditions over broad guesses.

Installation and Operation Guidance

Wrong setup often triggers belt breakdowns. Pulling, aligning, and linking all play roles.

Straightforward advice from the supplier trims prep time and cuts chances of prompt harm, particularly for distant buyers managing setup on their own.

After-Sales Response and Troubleshooting

When problems crop up, quick reply counts. Suppliers versed in their goods can spot roots fast, avoiding fuzzy tips.

UYANG BELTING backs buyers with tech input drawn from solid product insight, beyond routine responses.

Does the Supplier Offer Long-Term Value Beyond Price?

Cheap initial outlay seems appealing at first, but a conveyor belt’s true cost emerges across weeks and seasons. Regular swaps, missed output hours, and upkeep work pile up quickly.

Lasting worth arises from equilibrium, not quick fixes.

Belt Service Life and Replacement Cycles

Belts such as the Blue Glossy PVC Conveyor Belt are made for even running and simple wiping, which lessens top harm and erosion. Extended run length means rarer pauses and steadier upkeep schedules.

Supply Stability and Lead Time Control

Shaky delivery adds pressure to making plans. Dependable timelines aid makers in dodging urgent buys and hasty calls.

UYANG BELTING stresses steady making timelines to meet routine delivery wants, notably for overseas buyers.

Partnership Potential for Workflow Improvement

As time passes, suppliers who know a buyer’s path can propose sharper belt picks as steps evolve. Such teamwork frequently yields minor tweaks that boost full path output without big spending.

Conclusion

Assessing PVC conveyor belt suppliers amounts to more than a buy step. It shapes how evenly goods flow, how seldom paths halt, and how steady making stays.

From setup match and substance standards to tailoring and ongoing aid, the best supplier delivers beyond just goods. UYANG BELTING blends useful product builds, adaptable making, and field-based know-how to back varied carrier uses.

For firms seeking firm PVC conveyor belt fixes that suit true paths, checking the complete lineup at https://www.uyangbelt.com/ serves as a solid starting point.

FAQs

Q1: How do I know which PVC conveyor belt surface is right for my application?

A: Main points include item kind, slope degree, and needed steadiness. Even layers fit quick, light carries, whereas designed layers aid in managing shifts. Giving setup facts to the supplier aids in pinning the top pick.

Q2: Are oil-resistant PVC conveyor belts suitable for continuous operation?

A: Yes. Belts like oil-resistant PVC kinds are built for ongoing contact with fats and liquids, which helps limit top harm and prompt breakdowns in tough spots.

Q3: Can PVC conveyor belts be customized for non-standard machines?

A: Many makers, including UYANG BELTING, provide tailored spans, depths, and builds to suit odd or OEM gear, cutting the push for gear changes.