Food processing lines operate with a steady rhythm. When raw materials shift smoothly from one stage to the next, production output remains consistent, waste levels drop low, and overall quality holds firm. Yet, this smooth flow relies on a vital part that deserves more focus: the conveyor belt.

In places like bakeries, snack factories, and plants for packaged foods, PVC conveyor belts stand as a common pick. They stay clean, bend easily, and suit light to medium tasks in food handling. However, not all PVC belts perform alike. Factors such as surface texture, inner build, and material coating influence how food items act during transport.

UYANG BELTING has dedicated years to providing PVC conveyor belts tailored for food processing and bakery settings. By aligning belt features with actual production demands, the proper choice can resolve ongoing issues that hinder line speed on a daily basis.

What Challenges Do Food Processing Lines Face When Selecting A Conveyor Belt?

Picking a conveyor belt for food processing seldom boils down to just size and speed checks. Managers in production often deal with a blend of hygiene rules, sensitive products, and mechanical needs that fail to align simply.

Before diving into belt choices, it pays to outline the typical hurdles found in food production setups.

Sanitation And Cleanliness Requirements

Standards for food safety allow scant margin for mistakes. Conveyor belts endure regular cleaning without failing or trapping leftovers. Substances like oils, flour particles, dampness, and sugar bits challenge both the belt’s outer layer and its core.

People favor PVC belts since they withstand various food chemicals and clean up more readily than rubber or plain fabric versions. Even so, the surface type counts a lot. A belt that catches bits or soaks up water can make everyday cleaning a real chore.

Surface Texture And Product Handling

Food items move in varied ways on a belt in motion. Items such as soft dough, baked loaves, frozen goods, and boxed products each require a surface matched to their mass and feel.

Excessive hold might harm tender goods, while insufficient hold leads to slides, piles, or irregular gaps. In bakery operations particularly, selecting the belt surface impacts not only transport but also the final appearance of the items.

Durability And Longevity Concerns

Food facilities typically run extended shifts with little pause. A belt that frays quickly or elongates unevenly triggers alignment problems and unexpected halts.

True durability doesn’t always call for thick or stiff builds. For numerous food lines, the key is a belt that remains steady, retains form, and withstands routine washes without splits or separation.

Best Conveyor Belt Solutions From UYANG BELTING For Food Processing Lines

Grasping these hurdles aids in focusing options. The following move involves selecting belt types proven effective in food and bakery work.

UYANG BELTING provides various PVC conveyor belt choices crafted from practical processing scenarios, rather than mere test data. Each listed belt fills a distinct purpose in food handling systems.

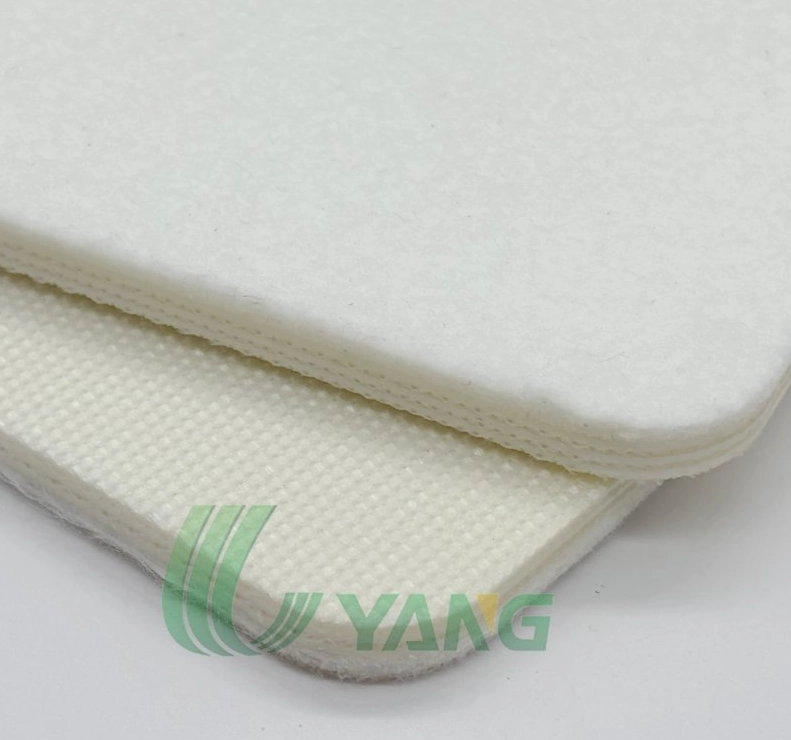

3-Ply White Felt Bakery Conveyor Belt — Soft Surface For Gentle Handling

Numerous bakery goods demand transport without heavy pressure, scraping, or abrupt hold shifts. Fresh dough, risen pieces, and completed loaves all gain from a milder touch surface.

The 3-Ply White Felt Bakery Conveyor Belt from UYANG BELTING fits this need precisely, as its felt upper layer forms a padded area that cradles items evenly through shaping, rising, or cooling phases.

Beneath that, the three-layer setup ensures firmness, allowing the belt to lie flat and follow paths accurately even over prolonged operations. Moreover, the pale surface aids visual checks and meets typical food safety guidelines in bakery areas.

Operators use this belt often in spots where careful treatment outweighs strong friction, such as bread production, pastry making, and simple snack runs.

Diamond PVC Conveyor Belt — High Grip And Wear Resistance

Not every food item requires delicate care. Certain tasks call for firmer hold to avoid slips, particularly on sloped paths or zones where alignment stays crucial.

The Diamond PVC Conveyor Belt employs an elevated diamond design that boosts traction yet keeps washing straightforward. This patterned top secures goods during handoffs, sorting steps, or prep for packing.

Processors select this for sealed items, trays, or weightier foods needing precise motion. The PVC build endures ongoing cleans and delivers reliable wear protection in active lines.

For those facing slide problems or irregular flows, this belt strikes a useful balance of hold and sanitation.

PVC Conveyor Belt — Cotton Top For Bakery Processing

In certain bakery tasks, felt tops prove overly yielding, whereas plain PVC feels overly smooth. The balanced option lies with cotton-top PVC belts.

The PVC Conveyor Belt with Cotton Top from UYANG BELTING merges a PVC foundation with a cotton cloth layer. This combination delivers fair traction while maintaining a soft enough touch for oven-fresh items.

Such cotton-top belts find common use in dough rolling, midway shifts, and cooling paths. The top layer cuts down on adhesion and permits airflow near heated goods.

In bakeries with diverse outputs, this belt acts as a versatile fix that adjusts to varying items without constant swaps.

How To Choose The Right Belt For Your Specific Food Processing Needs?

Given multiple fitting belt varieties, the ultimate pick hinges on pairing features with on-site conditions. A belt thriving in one facility might not suit another perfectly.

Several straightforward reviews can guide the selection.

Match Belt Surface With Product Type

Begin with the goods in question. Tender, raw, or breakable pieces generally call for felt or cotton layers. Sealed or bulkier ones tend to work better on patterned PVC tops.

Observing item actions during trial runs often uncovers issues beyond written details. Signs like gliding, jolting, or clinging typically signal a poor surface fit.

Evaluate Working Environment And Sanitary Standards

Heat levels, wetness, and wash schedules all impact belt lifespan. Damp rinses, regular disinfection, or oil contact demand materials that repel soaking and outer wear.

In food processing, folks pick PVC belts for their edge over other options in such settings, though the build of the surface still plays a role.

Consider Longevity And Maintenance Costs

An inexpensive initial buy that demands quick replacements can hike ongoing costs subtly. Factors like firmness, path accuracy, and stretch resistance determine how much upkeep crews intervene.

UYANG BELTING crafts its food-safe PVC belts with uniform layers and fabrics, which cut interruptions and swap needs in production flows.

Conclusion

Picking the ideal PVC conveyor belt for a food processing setup involves less seeking one top choice and more finding a solid match. Details like item kind, transport demands, and cleanliness rules all guide that call.

UYANG BELTING supplies a targeted lineup of PVC conveyor belts made for actual food processing sites. Ranging from mild felt tops for fragile bakery pieces to diamond-pattern PVC for steady flows, every choice tackles a particular line issue.

When operators select a belt suited to the workflow rather than adapting the workflow to the belt, manufacturers keep operations fluid, trim waste, and ensure steady quality over time.

FAQ

Q1: Are PVC conveyor belts suitable for direct food contact?

A: Yes. Food-grade PVC conveyor belts see broad use in food processing and bakery lines. Surface style and wash habits remain important, but PVC generally fits food zones well.

Q2: How often should food processing conveyor belts be replaced?

A: Timing for swaps varies by use rate, clean frequency, and belt makeup. Aptly chosen PVC belts with firm builds tend to endure far longer than mismatched ones.

Q3: Can different belt surfaces be used on the same production line?

A: Yes. Plenty of food sites employ varied belt types across phases, like felt for dough work and patterned PVC for packing or shift spots.