Picking the correct conveyor belt material has a subtle yet essential influence on routine manufacturing. In fields ranging from food processing setups to robust industrial hauling, the belt’s efficiency directly influences operational continuity, employee protection, and extended expenses. Within polymer choices, lightweight PVC conveyor belts and heavy-duty rubber conveyor belts continue to be the top picks for evaluation.

This piece analyzes the genuine contrasts between PVC and rubber conveyor belts, details the settings where each substance shines, and spotlights real-world item samples from UYANG BELTING, a supplier noted for dependable quality, uniform substances, and layouts prepared for sector needs.

Overview Of Conveyor Belt Materials

Prior to assessing positives and negatives, grasping the ways PVC and rubber belts vary at their core substance level proves beneficial. Their inner composition and outer actions account for the majority of efficiency disparities noted in actual uses.

What Is PVC Conveyor Belt

PVC conveyor belts consist of polyvinyl chloride blended with textile plies for reinforcement. This yields a belt that remains lightweight, bendable, and simple to manage amid setup.

Such belts see broad application in packaging, food management, logistics, and modest production lines. Their level exterior aids in cutting friction, curbing particle collection, and simplifying washing. Hence, for processes that emphasize orderly flow and firm alignment, PVC belts commonly appear as the sensible pick.

What Is Heavy-Duty Rubber Conveyor Belt

Rubber conveyor belts emphasize toughness from the start. Employing natural or artificial rubber blends, these belts manage elevated weights, firmer strikes, and coarse items without swift failure.

These belts frequently appear in mining, waste processing, building supply transport, and intensive factory environments. Their dense exterior buffers jolts effectively and holds adhesion even during tension, although this extra robustness brings added mass.

Key Differences Between PVC And Rubber Belts

The divide between PVC and rubber belts avoids declaring one superior. Instead, it concerns selecting the variant that matches the role without sparking concealed issues afterward.

Weight And Handling Comparison

PVC conveyor belts weigh considerably less. This factor holds greater significance than initial impressions suggest. Because of their reduced mass, such belts install more readily, tension with less effort, and exert minimal pressure on drive units and idlers. In smaller equipment or programmed setups, this lighter build typically results in even launches and diminished power use.

Rubber belts, conversely, possess a sturdy and hefty feel. While this mass bolsters substantial payloads, it also renders setup and care more drawn-out. Furthermore, in confined manufacturing areas, dealing with rubber belts generally calls for extra manpower or elevation aids.

Surface And Material Properties

PVC belts ordinarily feature level or shiny exteriors. These traits enable tidy item shifts, steady path following, and simple rinsing. Moreover, they endure various soft chemicals and greases, explaining their regular presence in food and packaging operations.

Rubber belts deliver firmer hold and greater tolerance to scraping. Their outer layer manages keen points, weighty falls, and steady rubbing more adeptly. That said, rubber layers might retain particles or leftovers more readily, which could ill-fit pristine areas.

Cost And Lifecycle Considerations

PVC conveyor belts generally involve lower starting costs. They further cut care durations since washing and renewal happen more swiftly. For modest to average duties, their working duration often suffices amply.

Rubber belts demand more at the outset, but within strenuous contexts, they persist beyond PVC options. In zones of strong impacts, these belts curb repeated halts from splits or outer erosion, thus evening out the steeper buying price.

Pros And Cons Of PVC Conveyor Belts

PVC belts lead in various current production pathways, yet they retain boundaries worth noting from the beginning.

Benefits Of PVC Belts

Handling PVC belts comes easily. Their slim framework lessens load on transport systems and permits quicker exchanges. Additionally, the level exterior facilitates neat progression of containers, pouches, and sealed merchandise.

These belts also function capably in spots where cleanliness counts. As PVC wards off humidity and numerous wash solutions, standard hygiene efforts simplify. Thus, for firms monitoring funds and output, PVC belts regularly align well.

Limitations Of PVC Belts

PVC belts lack design for intense blows. Keen substances, ongoing grinding, or raised warmth can trim their endurance. Moreover, should payload mass rise overly, PVC belts could extend or degrade swifter than foreseen. This renders them poorer fits for mining, alloy transport, or coarse waste handling.

Pros And Cons Of Heavy-Duty Rubber Conveyor Belts

Rubber belts enter the picture when situations turn rigorous and outer toughness surpasses pliability.

Advantages Of Rubber Belts

Rubber belts cope with rough handling adeptly. Their dense exterior takes in shocks, fends off rips, and sustains pull beneath dense weights. Sloped hauling and mass item movement thus often count on rubber belts for such qualities.

In addition, they operate more effectively in external or tough surroundings, where grit, scraps, and heat shifts mark everyday routines.

Drawbacks Of Rubber Belts

This boosted endurance adds heft. Rubber belts prove tougher to place and might heighten erosion on transport elements. Washing requires added work as well, notably in fields with sanitation guidelines. For milder tasks, rubber belts could exceed necessities.

How To Choose Between PVC And Rubber Belts

The fitting belt selection relies on true running scenarios, not vague notions.

Assessing Your Application Needs

Commence with the goods in transit. Slim containers, edibles, or wrapped wares typically signal PVC. Dense, pointed, or grinding items, however, demand rubber.

Then, weigh the locale. Spotless inner pathways prefer PVC. Gritty, open, or blow-laden spots frequently need rubber belts.

Performance Priorities And Budget

PVC belts back cheaper initial spend and simpler tending. Rubber belts back lasting power and scarcer renewals in dire spots. Pairing belt power to real duty load aids dodging excess payment or weak output.

UYANG BELTING Product Recommendations

UYANG BELTING provides both PVC and rubber conveyor belts crafted for genuine factory roles, beyond listing details.

Green Smooth PVC Conveyor Belt

The Green Smooth PVC Conveyor Belt targets firm, low-drag hauling. Its level exterior backs simple washing and even flow, fitting it for food prep, packaging routes, and basic fitting units. This belt excels where tidy looks and guided motion outweigh dense load endurance.

Blue Glossy PVC Conveyor Belt

The Blue Glossy PVC Conveyor Belt brings clear sight and cleanliness gains. The shiny layer aids fast spotting of remnants, valuable in precision areas. It slots nicely into food management, sorting routes, and tasks where belt purity sees regular review.

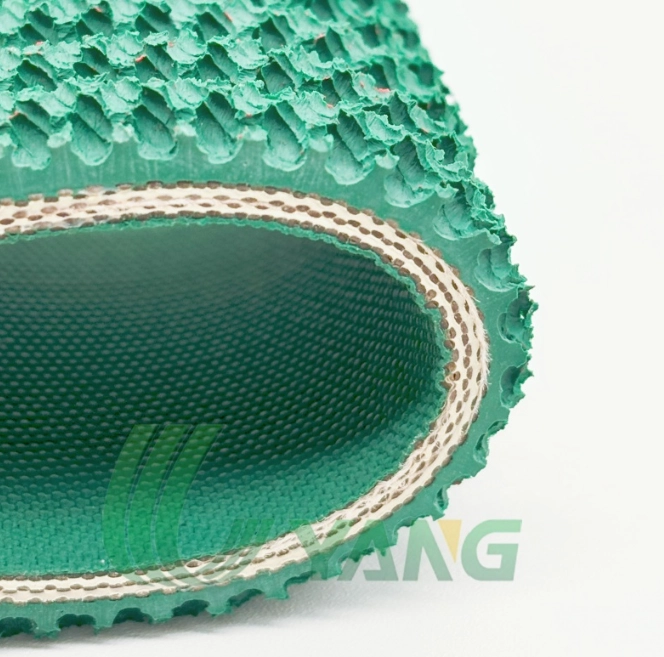

Green Nitrile Rubber Belt

The Green Nitrile Rubber Belt suits harder labors. With firm scrape tolerance and solid hold, it deals with denser weights and coarse items via lesser outer harm. This belt matches waste sites, factory hauling lines, and spots where PVC belts might erode too soon.

Practical Use Case Scenarios

Field examples in practice often shed light on belt picks clearer than spec sheets.

When To Choose PVC Belts

PVC belts serve optimally for modest to average weights, inner systems, and processes needing steady washing. Packing sites, food routes, and supply conveyors thus profit from their level exterior and simple dealing.

When To Choose Rubber Belts

Rubber belts align with dense items, strong blow areas, and angled hauling. Mining aid setups, waste centers, and structure supply lines thus lean on rubber belts for reliable action under duress.

Conclusion

Lightweight PVC and heavy-duty rubber conveyor belts fulfill specific aims. PVC belts aid tidy, effective, and thrift-minded processes, while rubber belts manage power, staying power, and coarse setups.

Knowing the true duty load, locale, and tending hopes steers to brighter picks. Via choices like UYANG BELTING’s PVC and rubber conveyor belts, makers can pair output needs without needless concessions.

FAQ

Q1: Can PVC conveyor belts handle oily materials?

A: PVC belts endure soft oils and chemicals, but steady heavy oil contact might trim belt span. There, nitrile rubber belts work superiorly.

Q2: Are rubber conveyor belts always more durable than PVC?

A: Rubber belts show more lasting under dense load and grinding, but in modest tasks PVC belts might hold as long with easier tending.

Q3: How often should conveyor belts be replaced?

A: Renewal hinges on load, locale, and tending. PVC belts in spotless spots can endure years, while rubber belts in rough spots may call for routine checks yet fewer sudden swaps.