In tire manufacturing, conveyor belts face tough challenges. Heat, oil, and heavy loads test them daily. A weak belt that breaks early can stop production, costing time and money. Selecting strong materials, smart designs, and proper care is essential. A reliable, well-made belt keeps tire lines running smoothly and safely, day in and day out.

Why Is Durability So Critical in Tire Manufacturing Belts?

Durability is a must in tire factories. It’s not just a bonus—it’s vital. Belts carry rubber sheets, cords, and unfinished tires through hot, high-pressure areas. If a belt rips or cracks, the whole line stops. This causes expensive repairs and delays. Belts need to handle constant weight, resist oils and chemicals, and stay tough in high heat. Each challenge tests the belt’s strength and upkeep.

Handling Constant Loads and Heat

Tire lines run nearly all the time. This puts heavy strain on belts. The top layer must resist wear from moving rubber and heat from curing machines. Heat-resistant PVC and PU belts work well. They don’t melt, stretch, or lose shape, even in hot conditions.

Resisting Oil and Chemical Exposure

During rubber mixing, oils and solvents can harm belts. Protective coatings or special PU layers help. PU-coated cotton canvas belts stay flexible and tough, even with daily chemical exposure.

Keeping Belt Tension and Alignment Right

Even strong belts wear out fast if tension is off. A misaligned belt rubs and tears on one side. Proper roller alignment and balanced tension reduce friction. This helps the belt last longer.

What Materials Deliver Long-Lasting Performance in Tire Factory Conveyors?

A belt’s material decides how it handles heat, pressure, and loads. In tire plants, polymer-based belts like PVC and PU are common. They’re strong, lightweight, and easy to clean.

Comparing PVC, PU, and Rubber Belts

Rubber belts are rugged but heavy. They suit extreme loads but need more upkeep. PVC belts are lighter and cheaper. They’re great for standard conveyor areas. PU belts are even better—they resist cuts, hold up under tension, and last longer during long shifts.

Benefits of Polyester-Reinforced Layers

Adding a woven polyester or cotton layer boosts strength. It keeps the belt flat and stable, even under tension or in humid conditions. Polyester-cotton fabric works well in tire factories. It stretches little and stays firm during long runs.

Choosing the Right Thickness for Heavy Tasks

Thickness affects strength and flexibility. Thin belts move quickly but wear out faster with heavy parts. A belt 2.5mm to 3.0mm thick is ideal for tire production. It supports weight, handles tension, and runs smoothly.

How Does Proper Belt Construction Improve Durability?

A belt’s performance depends on its materials and how it’s made. The inner structure and joints give it real strength.

Importance of Fabric Core and Weave Type

The fabric core acts like a belt’s backbone. Woven polyester or cotton spreads pressure evenly. A tight weave reduces the risk of splitting or peeling, even in hot settings.

Heat-Fused or Mechanically Joined? Understanding Joints

Joints are often the weak spot. Heat-fused joints use heat to bond smoothly. They last longer than mechanical joints, which can collect dust and wear out faster.

Coating Quality and Surface Textures for Better Grip

A belt’s surface affects material movement. Rough textures grip rubber sheets well. Smoother coatings help with release and transfer. The right surface keeps materials moving steadily and prevents slipping.

Which Conveyor Belt Designs Suit Tire Factory Environments Best?

Different tire production stages need specific belt strengths. From mixing raw materials to curing tires, each area requires a unique belt design.

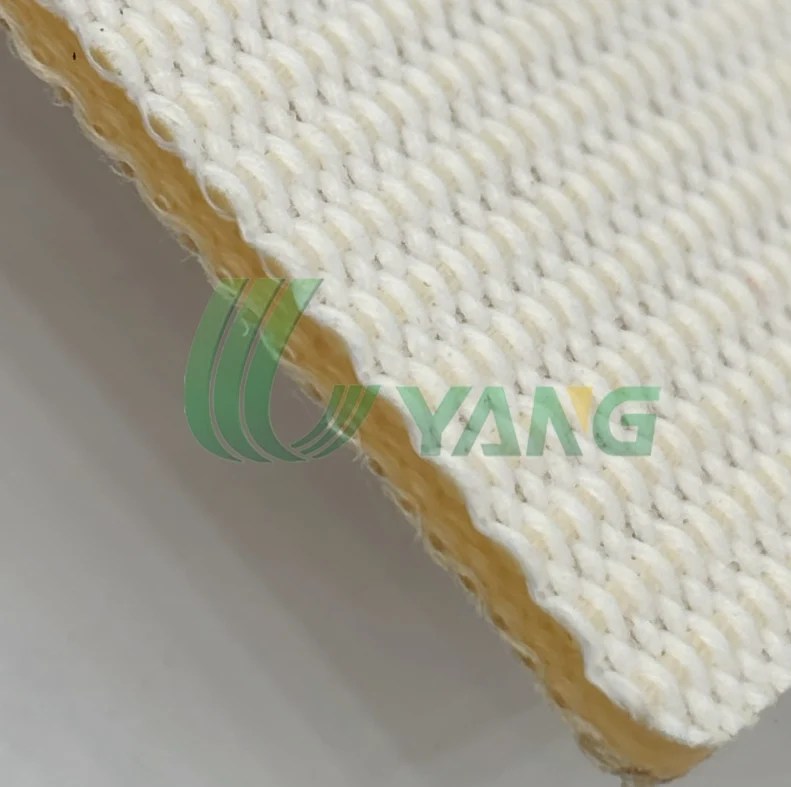

PVC Conveyor Belt – Polyester Woven Cotton Top – For Tire Factory – UYANG BELTING

This belt blends polyester strength with a soft cotton top. It grips rubber sheets without sticking. It’s flexible and reliable, ideal for general transfer zones with moderate heat and oil.

2.5 mm Cotton Canvas PU Conveyor Belt – For Tire Industry – UYANG BELTING

This PU belt suits mixing and calendaring areas. Its cotton canvas backing absorbs vibration and keeps the belt flat under changing pressure. It runs fast and handles frequent starts and stops easily.

3.0 mm Cotton Canvas PU Conveyor Belt – For Tire Production – UYANG BELTING

For heavy-duty areas like curing presses, this 3.0mm PU belt offers solid support. It resists heat, compression, and stretching. It stays reliable during long production hours.

How to Maintain Conveyor Belts for Extended Service Life?

Even the toughest belts need care. Regular cleaning and checks prevent sudden failures.

Routine Cleaning and Lubrication

Rubber dust and oil build up fast on belts. Daily cleaning with mild soap helps. In hot zones, lightly lubricating pulleys and bearings cuts friction and noise.

Tracking Belt Movement and Wear

A belt that drifts slightly can wear unevenly. Checking pulley tension and tracking keeps it straight. Marking one edge helps spot if it’s veering off.

Replacing Joints and Rollers on Time

If a joint peels or a roller cracks, replace it quickly. Waiting leads to longer downtime. Preventive fixes save money and keep belts in good shape.

What Are the Common Causes of Belt Failure and How to Prevent Them?

Most belt issues come from small mistakes—overloading, poor alignment, or skipping care. Catching these early avoids big problems.

Overloading and Slippage

Pushing belts past their weight limit stretches them. This shortens their life. Staying within capacity prevents slipping and tearing.

Damage from Chemicals or Heat

Heat and chemicals weaken belts over time. PU or heat-resistant PVC belts stay stronger longer.

Skipping Cleaning or Inspections

A bit of residue seems minor but causes drag and uneven tension. Weekly cleaning and roller checks can double a belt’s life.

Why Choose UYANG BELTING for Tire Industry Conveyor Solutions?

UYANG BELTING makes dependable belts for tough workloads. Their PVC and PU conveyor belts balance flexibility and toughness, perfect for demanding tire lines.

Proven Quality with Custom Support

Every belt is designed for real-world needs—heat, speed, and tension are considered. UYANG BELTING customizes surface texture, color, and joints to fit customer setups.

Wide Range for All Tire Production Stages

From mixing to final tire checks, their belts cover every step. The PVC Polyester Woven Cotton Top, 2.5 mm PU Canvas, and 3.0 mm PU Canvas models perform reliably worldwide.

Global Reach and Trusted Partnerships

UYANG BELTING serves tire manufacturers and OEMs globally. Their belts handle long runs, heavy loads, and tight schedules with ease.

Conclusion

Creating durable conveyor systems in tire plants takes effort. Use the right materials, install them correctly, and keep them clean and aligned. A strong belt means fewer stops, better safety, and smoother production. For tire makers, reliability starts with the belt that keeps the line moving.

FAQs

Q1: Q1: How long do tire factory conveyor belts usually last?

Most PVC or PU belts last one to two years with proper care. Heavier models like the 3.0 mm PU belt can last longer if maintained well.

Q2: Can PVC belts handle high heat during tire curing?

Standard PVC softens above 80°C. Reinforced types with polyester or cotton handle more heat. PU belts are better for hot zones.

Q3: How can I stop conveyor belts from slipping?

Balance tension and check pulleys for wear. Belts with textured or cotton tops grip rubber sheets better.