In places where keeping things clean is super important, picking the right conveyor belt matters a lot. From food factories to medicine plants, the materials used must stay safe and clean. Antibacterial and anti-mildew hygienic belts help with this. They keep things clean, safe, and long-lasting. This article explains what to look for when choosing these belts. We’ll focus on the strong Antibacterial and Anti-Mildew Hygienic Belts from Uyang Belting.

Introduction

Importance of Hygiene in Conveyor Belts

Conveyor belts move products through different steps in making, processing, and packing. In places like food or medicine factories, keeping things clean is a big deal. If the belt isn’t clean, products can get dirty. This could lead to recalls or health problems. So, choosing a clean conveyor belt is not just nice—it’s a must. It helps meet safety rules and keeps everyone safe.

Overview of Antibacterial and Anti-Mildew Belts

Antibacterial and anti-mildew belts are made to stop germs and mold from growing. They use special materials like Thermoplastic Polyurethane (TPU). TPU fights off germs and mold well. This makes it perfect for places that need to stay super clean. These belts are also easy to clean after each work shift. This helps keep things running smoothly and safely.

Key Factors to Consider When Choosing Hygienic Belts

Material Composition

The material of a hygienic belt is super important. It needs to be tough, stop germs, and handle strong cleaning.

Thermoplastic Polyurethane (TPU)

TPU is a great choice for hygienic belts. It’s flexible, strong, and fights off oil, chemicals, and germs. Uyang Belting uses top-quality TPU for their antibacterial and anti-mildew belts. These belts meet FDA rules, so they’re safe for food. TPU belts don’t break down in water or steam. This makes them easy to clean and keep in good shape.

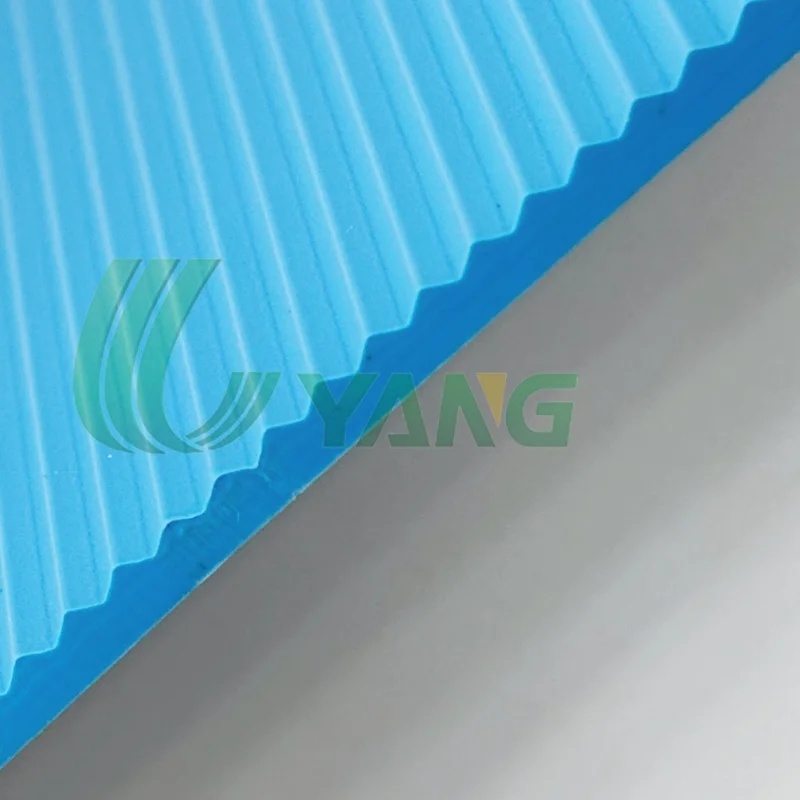

Smooth vs. Textured Surfaces

For super clean places, a smooth surface is best. Uyang Belting’s Antibacterial and Anti-Mildew Hygienic Belts have a smooth finish. This makes them easy to clean quickly. Sometimes, bumpy surfaces are used for extra grip. But they need to be designed so dirt doesn’t get trapped.

Seamless vs. Spliced Edges

The edges of a belt matter too. Seamless belts are great because they stop germs from hiding. Uyang Belting’s Antibacterial and Anti-Mildew Hygienic Belts use heat to make smooth, seamless edges. This gets rid of spots where germs could grow. Spliced belts have seams that can collect dirt. These are harder to keep clean.

Compliance with Standards

Hygienic belts must follow strict rules to make sure they’re safe for industries like food and medicine.

FDA and EU Regulations

Uyang Belting’s Antibacterial and Anti-Mildew Hygienic Belts meet FDA and EU rules. This means they’re safe to touch food. These certifications are a must for companies in food or other regulated work. They show the belts won’t make products unsafe.

Benefits of Antibacterial and Anti-Mildew Belts

Enhanced Hygiene and Safety

TPU naturally fights germs and mold. This lowers the chance of products getting dirty. These belts are perfect for places where food safety or medicine quality can’t be compromised.

Durability and Longevity

Antibacterial and Anti-Mildew Hygienic Belts are tough compared to other materials. They can handle heavy loads, hot temperatures, and chemicals or water. Uyang Belting’s Antibacterial and Anti-Mildew Hygienic Belts last a long time. This means fewer replacements and less time when machines are stopped.

Cost-Effectiveness in the Long Run

It might cost a bit more at first. But they save money over time. They last longer and need less cleaning. This cuts down on repair costs and keeps machines running. This makes them a smart choice for food, medicine, and medical companies.

Applications Across Industries

Food Processing

In food factories, keeping things clean is a must. Uyang Belting’s Antibacterial and Anti-Mildew Hygienic Belts are great for moving food without making it dirty. Their smooth surface and seamless design make cleaning easy. They meet high safety rules set by groups like the FDA and EU.

Pharmaceuticals

Medicine factories need very clean conditions. Uyang Belting’s Antibacterial and Anti-Mildew Hygienic Belts work well here. They have a non-porous surface that stops germs. This keeps medicines safe and clean during production.

Other High-Hygiene Environments

Antibacterial and Anti-Mildew Hygienic Belts are also used in places like meat, seafood, or dairy factories. They’re great for medical work too. These belts help keep things super clean. They make sure products are moved safely and quickly in many industries.

Maintenance and Care

Cleaning Protocols

Uyang Belting’s Antibacterial and Anti-Mildew Hygienic Belts are easy to clean. Their smooth, non-porous surface lets you wash them quickly. Use mild soap after each shift. Do a deeper clean weekly with steam or chlorine cleaners. This keeps the belts germ-free and safe.

Inspection and Replacement Guidelines

Check belts often to keep them working well. Uyang Belting suggests looking for cuts, swelling, or bad joints. Make sure the belt stays tight and lined up right. This stops slipping and keeps things running smoothly. If you see damage, replace the belt right away to keep things clean.

Conclusion

Summary of Key Considerations

When picking antibacterial and anti-mildew hygienic belts, think about the material, surface, rules, and cleaning ease. Uyang Belting’s Antibacterial and Anti-Mildew Hygienic Belts offer great cleanliness, toughness, and value.

Final Recommendations

For food, medicine, or medical work, Uyang Belting’s TPU antibacterial and anti-mildew belts are a great pick. They keep things clean, last long, and are easy to clean. These belts help keep operations safe, fast, and up to strict standards.

FAQ

Q1. What are the main benefits of TPU antibacterial and anti-mildew belts?

A: TPU belts keep things clean, last long, and fight germs. They’re easy to wash, meet food safety rules, and work well in clean industries.

Q2. Can Antibacterial and Anti-Mildew Hygienic Belts be used in food processing?

A: Yes. They meet FDA and EU rules, so they’re safe for food. They’re great for places where cleanliness is super important.

Q3. How should Antibacterial and Anti-Mildew Hygienic Belts be cleaned and maintained?

A: Clean them with mild soap after each shift. Do a deep clean weekly with steam or chlorine cleaners. Check them often to keep them in good shape.