In large-scale baking operations, even the tiniest snag in the manufacturing process can disrupt a whole day’s timetable. At UYANG BELTING, the emphasis remains on tackling those exact equipment problems, such as dough clinging to the surface or borders wearing out after only several months of intense operation. Selecting the proper belt goes beyond simply shifting goods from one spot to another, for it ensures that the dough remains whole and the assembly continues steadily without frequent hands-on adjustments.

Why Is Dough Adhesion a Major Challenge in Bakery Production?

Managing flour, water, and sugar poses real difficulties for ordinary conveyor substances. When the dough attaches to the outer layer, it causes “carry-back,” meaning small portions of material curl around the rollers, leading to sanitation concerns and cluttered accumulations.

Impact of Sticky Dough on Production Efficiency

Each instance when a staff member halts the assembly to remove adhered dough, earnings suffer. In a brisk bakery setting, just a handful of moments’ delay in every round builds up to several hours of forfeited output across a week, and moreover, the hand scraping frequently harms the belt’s outer, thereby cutting its useful duration.

Common Material Limitations of Standard Conveyor Belts

Everyday belts typically miss the precise detachment qualities required for adhesive dough. They could prove overly adhesive or respond badly to the lipids and greases involved in pastry preparation, and as time passes, these substances may turn absorbent, capturing microbes and rendering thorough sanitizing almost unfeasible.

Benefits of Choosing Specialized Non-Stick Belts from UYANG BELTING

Through employing substances precisely developed for food processing, UYANG BELTING assists bakeries in reaching their manufacturing goals without the disorder. These belts construct to cope with the distinct composition of rising dough, guaranteeing a neat separation whenever the item reaches the subsequent phase of the assembly.

How Does the 3-Ply White Felt Belt Ensure Soft Surface Handling?

For fragile products like croissants or tender loaves, a rigid plastic outer can act too forcefully. One requires a material that permits airflow and softens the impact on the item, and here the felt material proves effective.

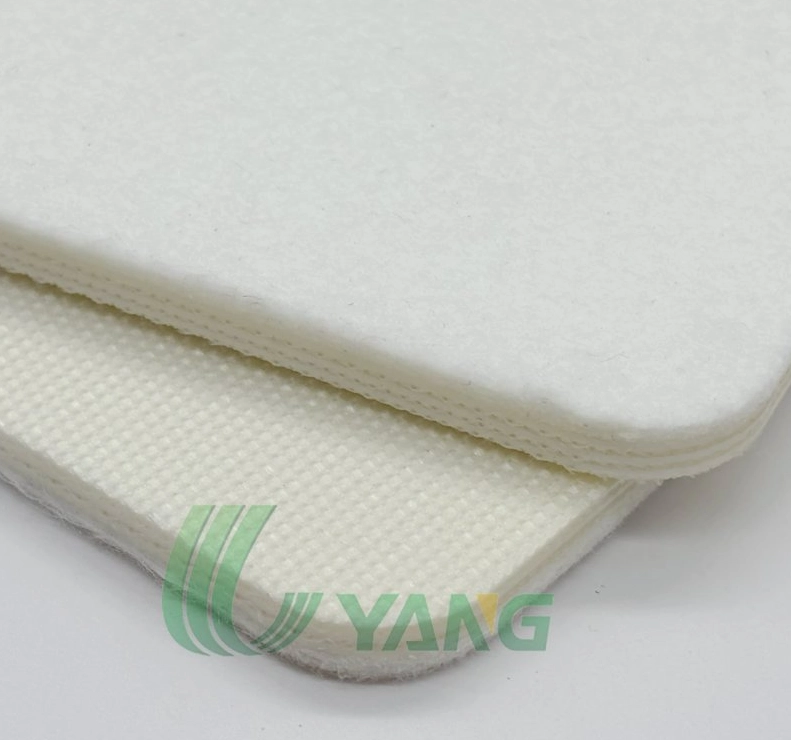

Gentle Transport with UYANG BELTING’s 3-Ply White Felt Surface

The 3-Ply White Felt Bakery Conveyor Belt serves as a preferred choice for bakers seeking a mild contact. The felt outer functions as a buffer, stopping the dough from altering shape while moving, which holds key importance for preserving the visual appeal of high-end baked items.

Superior Absorption Properties for High-Moisture Dough Applications

Doughs with elevated water content remain particularly tough to control. The felt substance aids by taking in a small amount of surplus outer wetness, which in fact forms a inherent anti-adhesion layer, and this approach blends traditional baking knowledge with contemporary belt engineering.

Multi-Layer Fabric Support for Enhanced Belt Stability and Longevity

The term “soft” should not mislead anyone, since with three layers of robust fabric below, this belt resists elongation or distortion readily. It maintains alignment and operates accurately, even amid the warmth and dampness that arise in a bakery during busy periods.

What Makes PVC Belts with Polyester Fabrics Ideal for Confectionery?

Candy production and sweetened breads introduce varied issues, mainly related to sugar and substantial fat levels. Such a belt must endure these components without deteriorating quickly.

High Resistance to Food-Grade Oils and Sugars

The PVC Conveyor Belt with Polyester Fabrics creates to withstand the adhesive elements. Be it coated pastries or sweet cookies, the PVC layer avoids splitting or weakening upon contact with the common fats and sugars in candy making.

Seamless Integration into High-Speed Processing Lines

These belts design for rapid operation. Owing to their light weight and pliability, they coil around compact drums with ease, rendering them suitable for confined equipment where area limits exist yet production volumes must remain elevated.

UYANG BELTING’s Polyester Fabric Reinforcement for Low Stretch

A frequent issue with low-cost belts involves them extending after a brief period. UYANG incorporates a particular pattern in the polyester weave that sustains the belt’s tautness steadily, which results in reduced tuning needs and minimized interruption for upkeep teams.

Is a Cotton Top PVC Belt the Best Solution for Flour-Heavy Environments?

In areas filled with flour dust, a typical even belt might become slick or, on the other hand, form a glue-like substance that adheres. Cotton delivers a feel that cooperates with the flour instead of opposing it.

Natural Release Properties of UYANG BELTING’s Cotton Top Surface

The Cotton Top PVC Conveyor Belt provides a balanced option. Its cotton upper enables straightforward detachment of dough portions, establishing it as a top pick for rising stages and cookie forming where the dough must lift cleanly from the surface.

Excellent Air Permeability for Cooling and Proofing Stages

Dough benefits from ventilation. The cotton strands permit some circulation beneath the item, offering significant support in the chilling period or during resting in the proofer, and this avoids the damp underside issue that occurs on unbroken plastic surfaces.

Hybrid Construction Combining Natural Fiber and Durable PVC Base

This setup yields advantages from each side. The upper consists of organic cotton for optimal dough management, whereas the lower features sturdy PVC. Such a thoughtful arrangement manages the pressure from the drums while maintaining the food-facing part precisely suited to the baker’s requirements.

How to Choose the Right UYANG BELTING Solution for Your Bakery?

Each bakery operates uniquely, so no universal belt exists that suits every case. Factors like the dough’s tackiness, ambient heat, and carried load must guide the decision.

Matching Belt Surface Materials to Specific Dough Consistency

For highly greasy dough, select the PVC variant. If the mix stays loose and light, the felt likely excels. Everything hinges on the dough’s surface pull interacting with the belt’s pattern.

Evaluating Temperature and Load Requirements for Different Stages

A belt employed in ambient chilling differs in needs from one passing through a warmer. It remains vital to review the heat tolerance of the belt substance to confirm it avoids becoming rigid or overly pliant in the given conditions.

Consulting UYANG BELTING Experts for Customized Sizing and Specifications

Occasionally, a particular breadth or joining method proves necessary for smooth function. The specialists at UYANG BELTING possess broad experience and can determine the measurements and substances that endure on the exact machinery in use.

FAQ

Q: Can these belts be used for direct contact with raw dough?

A: Yes, indeed. All referenced belts, including the felt, cotton upper, or PVC types, utilize food-approved materials that comply with protection guidelines for immediate food product interaction.

Q: How do I clean a felt or cotton top belt compared to a smooth PVC one?

A: The even PVC wipes quickly. Regarding felt and cotton, a dry brush or gentle suction works well to clear flour residue, and if deeply marked, they handle cleaning with dedicated safe agents, though immersion should be avoided.

Q: How long should I expect my UYANG BELTING bakery belt to last?

A: The duration varies with usage intensity, but proper tightening and upkeep allow these belts to serve extended industrial periods, and the polyester strengthening in the foundation effectively counters the drooping and lengthening that affect inferior options.