Woodworking is a rough job for equipment. Sawdust piles up, heavy logs bang around, and sticky resin gums things up fast. A good conveyor belt isn’t just about moving stuff along—it saves you time, cuts down on costs, and keeps your operation running without constant fixes.

UYANG BELTING, with over 20 years in the business, makes belts that can handle the mess of wood processing. Their Capsule Stud PVC Conveyor Belt and Square Pattern PVC Conveyor Belt are built tough for this work. Let’s dig into what you need to think about to pick a belt that’ll hold up.

Why Is Picking the Right Material So Important for Wood Processing Belts

The material your belt is made of can make all the difference. Wood processing throws a lot at you—abrasive surfaces, heavy timber, and sap that sticks like nobody’s business. A bad choice means you’re stuck with breakdowns or swapping belts too often.

Stands Up to Wear

Hardwoods like oak or maple chew through weak belts. UYANG BELTING’s Capsule Stud PVC Conveyor Belt uses tough PVC that doesn’t flinch at scratches. I saw a sawmill in Oregon last summer where their belts moved tons of rough lumber every day for over a year, still looking solid. Compare that to cheap belts that fell apart in months.

Works with All Kinds of Wood

Wood varies a lot. Pine’s light but full of sticky sap. Cherry’s heavy and dense. UYANG’s belts take on both without stretching or breaking. Their PVC stays flexible but strong, handling any wood’s weight or stickiness.

Follows Safety Rules

Safety’s non-negotiable. If your plant makes wooden crates for food, your belts have to meet strict standards. UYANG BELTING’s belts carry ISO 9001:2015 certification. They can also hit FDA standards, so your operation stays safe and above board.

How Does a Belt’s Pattern Change Wood Processing

A belt’s pattern isn’t just decoration. In woodworking, it’s about keeping wood in place, making sure things stay steady, and moving materials without a hitch. A good pattern stops logs from sliding and keeps your line humming.

Grips Tight and Keeps Steady

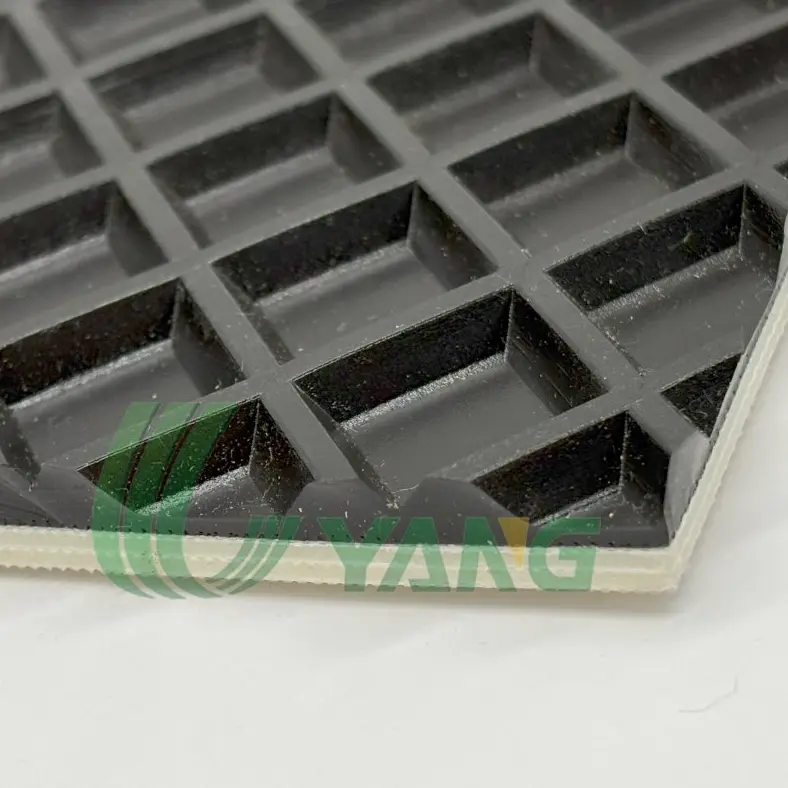

UYANG’s Square Pattern PVC Conveyor Belt has a textured surface that holds wood like a pro. The square design grabs on tight, perfect for hauling logs up slopes as steep as 16 degrees. It’s a lifesaver in mills where slick wood causes holdups.

Stops Slipping

Nothing’s worse than a log sliding backward. UYANG’s Capsule Stud PVC Conveyor Belt has little raised bumps that lock wood down. A guy from a Canadian mill told me this belt cut their slipping problems by 30%. It kept things moving, even in damp conditions.

Spreads Weight Evenly

Big timber can stress a belt unevenly, leading to rips. UYANG’s square and capsule patterns spread the load across the belt’s surface. This cuts down wear and makes the belt last longer, even when moving massive oak beams.

Why Does a Belt’s Toughness Matter in Woodworking

A belt’s toughness isn’t just about lasting forever. It’s about surviving the daily grind of a wood plant. Heavy loads and rough conditions demand a belt that won’t quit.

Handles Heavy Timber

UYANG’s Capsule Stud PVC Conveyor Belt carries big loads without a problem. In a U.S. lumber yard, these belts hauled 500 tons of wood a week. After 18 months, they still looked nearly new. That kind of strength means fewer replacements.

Holds Up in Harsh Settings

Wood plants can be wet, dusty, or swing between hot and cold. UYANG’s PVC belts don’t soak up water, so they won’t swell or warp. They also stay tough in cold places, like Canadian winters, where weaker belts might snap.

Saves Money on Fixes

A strong belt means less time fixing stuff. UYANG’s belts are made to take a beating, so you spend less on repairs. One client said they saved $10,000 a year on upkeep after switching to UYANG’s belts. That’s money you can put back into your business.

How Can Customizing a Belt Help Your Wood Processing

No two wood plants are the same. You might be slicing thin veneers or hauling huge logs. A standard belt doesn’t always cut it. That’s where UYANG BELTING really steps up.

Belts Made to Fit

UYANG offers belts in all sorts of widths, thicknesses (1.5mm to 5mm), and lengths to match your setup. Got a small router or a giant sawmill? They’ll sort you out. Their team helps you figure out the exact specs you need.

Patterns for Your Needs

The Capsule Stud and Square Pattern PVC belts are built for wood. Studs grip odd-shaped logs tight. Squares are great for flat planks. You can even ask for custom textures, like extra grip for soggy wood.

Branding and Special Features

Want your logo on the belt or a color that stands out? UYANG’s OEM/ODM services let you tweak branding or add special features. It’s perfect for plants with unique setups.

Why Does Easy Cleaning Matter for Wood Processing Belts

Wood processing gets messy fast. Resin, sawdust, and oils build up quick, turning belts into a sticky disaster. A belt that’s easy to clean keeps your line moving and your workplace safe.

Keeps Resin Off

Resin can clog things up. UYANG’s PVC belts have a slick surface that pushes back against sap and pitch. A quick spray with a hose, and the belt’s clean—no elbow grease needed.

Meets Cleanliness Standards

Some wood plants make crates for food, like fruit or veggies. UYANG’s belts can meet FDA and EU 10/2011 standards, so you don’t risk contamination. This is huge if your plant handles different products.

Saves Time on Cleaning

Cleaning steals time from making stuff. UYANG’s belts are built for quick washdowns, often taking half the time of older belts. One mill cut their cleaning time by 40% with UYANG’s Capsule Stud belt.

How Does Setting Up a Belt Affect Your Work

Even the best belt’s no good if it’s not set up right. Bad installation means slipping, wear, or even breakdowns. Doing it right from the get-go keeps things running smooth.

Gets Tension and Fit Right

UYANG gives clear instructions for setting tension and alignment. Too tight, and the belt stretches out. Too loose, and it slips. Their belts are simple to set up, even if you’re new to it.

Help from Experts

Not sure where to start? UYANG offers remote and on-site help. Their team’s set up belts in over 50 countries, from tiny shops to huge mills.

Fits Your Equipment

Got an old conveyor or a shiny new line? UYANG’s belts work with both. Their Capsule Stud and Square Pattern belts fit standard pulleys and rollers, so you don’t need to redo your whole system.

What Makes UYANG BELTING a Solid Pick for Wood Processing

Picking a supplier is just as big as picking the belt. UYANG BELTING’s been at it for 20 years, and their track record shows they’re the real deal.

Knows the Industry Inside Out

With an 80,000-square-meter factory and 15 high-tech production lines, UYANG delivers. Their belts are used in sawmills, furniture plants, and plywood factories from the U.S. to Asia.

Great Products for Wood

The Capsule Stud PVC Conveyor Belt and Square Pattern PVC Conveyor Belt are made for wood processing. They handle everything from raw logs to finished panels, with features like wear resistance and custom patterns that keep things moving.

Awesome Support After You Buy

UYANG doesn’t just hand you a belt and walk away. They give a 12-month warranty and lifelong technical help. Got a problem? Their 24/7 hotline and remote fixes get you back on track fast.

Picking a conveyor belt for woodworking isn’t just about the numbers. It’s about finding a company that gets what you need. UYANG BELTING’s focus on tough belts, custom options, and solid support makes them a top pick. Their Capsule Stud and Square Pattern PVC belts are ready for the hardest wood jobs, from small shops to big mills. When you’re choosing a belt, think about what’ll keep your line running strong for years. Trust me, I’ve seen plants go cheap on belts and kick themselves later—don’t make that mistake.

FAQ

Q1: How often should I replace my wood processing conveyor belt?

A: Depends on how much you use it. UYANG’s PVC belts usually last 1-3 years with heavy loads. Check for wear or resin buildup regularly to stretch their life.

Q2: Can UYANG’s belts handle wet or resin-heavy wood?

A: Yup. Their Capsule Stud and Square Pattern PVC belts push back against water and sap, making them great for wet or sticky wood.

Q3: What’s the lead time for a custom belt from UYANG BELTING?

A: Standard orders take 15-25 days. Need it quick? UYANG’s 7-day express service has you covered, but it’ll cost a bit more.