PVC conveyor belts serve a vital function in today’s material handling tasks, particularly in areas like food processing, packaging, logistics, and light manufacturing. When these belts operate without hitches, production flows steadily. However, if they break down, minor problems can halt the entire line. Routine upkeep goes beyond simple fixes; it ensures that daily operations remain reliable and expenses stay in check.

UYANG BELTING specializes in PVC conveyor belt options crafted for extended durability, straightforward cleaning, and consistent output in various sectors. By learning how to care for these belts effectively, companies can maximize their equipment’s worth and sidestep avoidable interruptions.

Why Should You Maintain Your PVC Conveyor Belts Regularly?

Although PVC belts are constructed to endure tough conditions, none will function optimally without proper oversight. Upkeep isn’t merely a mechanical chore; rather, it forms a key element in ongoing production strategies.

Belt Longevity And Performance Benefits

A carefully tended PVC conveyor belt endures far longer than one left unattended. Everyday rubbing, item impacts, and wash cycles gradually impact the belt’s outer layer. In due course, tiny splits or outer erosion can develop into major harm.

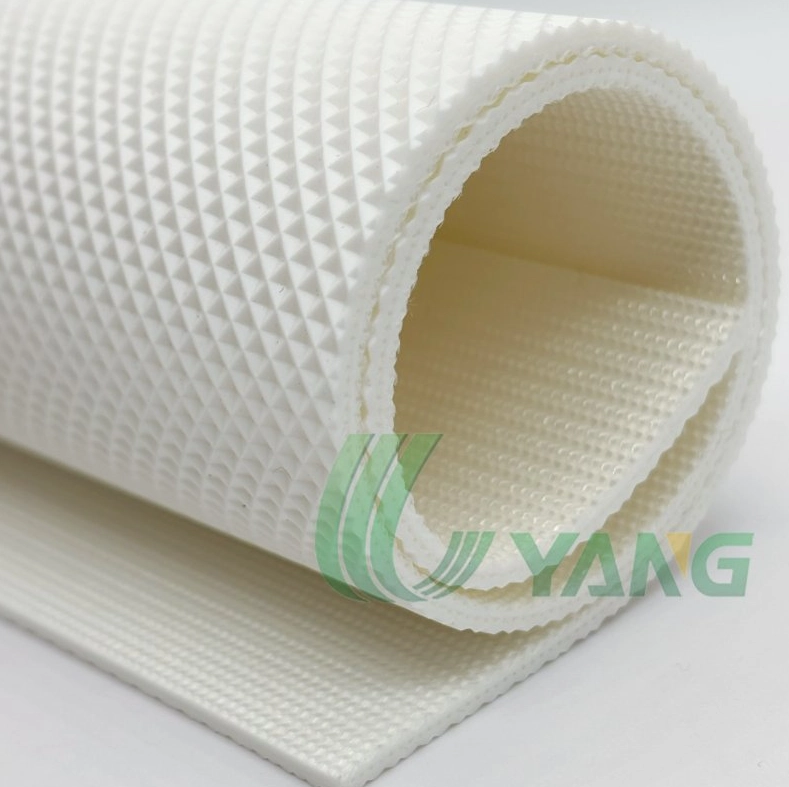

Frequent examinations help maintain the belt’s outer layer smooth and pliable. For instance, patterned belts such as the White Diamond PVC Conveyor Belt from UYANG BELTING are built to manage ongoing contact, yet they retain firm holding power. Basic actions—like inspecting the outer state and side erosion—safeguard that design and prevent premature swaps.

Reduced Downtime And Operational Costs

Sudden belt breakdowns frequently trigger abrupt halts in output. Such pauses typically prove costlier than scheduled upkeep, particularly during rushed orders or when staff is already lined up.

Standard belt tending cuts the risk of urgent fixes. As belts get wiped, straightened, and tightened promptly, the engines and cylinders experience less pressure. Consequently, this leads to fewer malfunctions throughout the whole conveyor setup, extending beyond just the belt.

Enhanced Safety And Sanitation Standards

Within fields like food handling, the belt’s state directly influences security and cleanliness. Broken or flawed outer layers can hold onto leftovers, posing health hazards.

Food-safe PVC belts, including UYANG BELTING’s White Felt Bakery Conveyor Belt, are engineered for hygienic transport. Steady upkeep ensures the outer layer stays even and simple to rinse, allowing processes to comply with cleanliness guidelines effortlessly.

What Are The Common Issues Affecting PVC Conveyor Belts?

Even sturdy belts encounter troubles if the environment isn’t handled wisely. Recognizing typical problems simplifies their avoidance.

Belt Wear And Surface Damage Causes

Outer erosion often stems from pointed items, too much rubbing, or wrong belt picks. If a belt meant for basic packaging handles heavier duties, the deterioration accelerates quickly.

Selecting the proper outer pattern is crucial. For example, diamond-style PVC belts suit tasks needing hold and resistance to scraping. Aligning the belt variety with actual job needs marks the initial move to curb erosion.

Contamination And Material Build-Up Challenges

Particles like dust, fats, flour, sugar, and oils commonly accumulate amid routine work. When ignored, these substances solidify and disrupt belt path and grip.

In baking and food settings, fabric belts face heightened exposure. The White Felt Bakery Conveyor Belt from UYANG BELTING is created for simple residue shedding, but it demands ongoing wiping to prevent buildup that might cut short its span.

Misalignment And Tension Problems

Off-center positioning acts as a subtle issue. The belt might continue moving, but sides begin to unravel, and the path grows unsteady. Typically, uneven pull or damaged cylinders cause this.

Initial clues involve sound shifts or belts veering aside. Correcting the positioning soon shields both the belt and the conveyor structure, dodging pricier fixes down the line.

How Do You Choose The Right PVC Conveyor Belt For Your Application?

Care begins prior to setup. A belt suited to the task inherently outlasts others.

White Diamond PVC Conveyor Belt As Durable Solution

The White Diamond PVC Conveyor Belt from UYANG BELTING suits jobs where hold, erosion resistance, and steadiness count. Its diamond upper layer minimizes sliding, particularly on sloped or intermittent transport routes.

This belt fits well in wrapping setups, shipping networks, and basic factory tasks where items require guided shifts. Moreover, its layered design curbs irregular erosion, simplifying everyday tending.

White Felt Bakery Conveyor Belt For Food-Grade Conveying

Baking tasks call for soft treatment and neat shifts. The White Felt Bakery Conveyor Belt delivers a gentle upper side that guards dough and finished items from harm, while permitting air flow and effortless letting go.

Operators often deploy this belt in chilling paths and baking shift systems. Although its fabric side needs suitable wiping plans, correct handling ensures dependable work even in steamy, moist spots.

White PVC Conveyor Belt For General Purpose Uses

For everyday transport jobs, the White PVC Conveyor Belt offers a well-rounded choice. It cleans easily, withstands various substances, and handles light to moderate weights.

This belt type gets picked for food wrapping, sorting paths, and minor factory hauls. Its level outer side limits leftover accumulation, speeding up standard wiping with less work.

What Are The Best Practices For Daily Cleaning Of PVC Conveyor Belts?

Wiping habits shape belt endurance directly. Minor daily routines often outweigh sporadic thorough scrubs.

Routine Surface Cleaning Techniques

Dry methods, including sweeping or blowing air, handle dust and free bits effectively. Use wet approaches for fats or clingy stuff.

Always wipe along the belt’s travel path. Going opposite can force junk further into the outer or sides, leading to lasting harm.

Appropriate Cleaning Tools And Agents

Gentle sweepers, safe-for-food soaps, and gentle water streams suffice in most cases. Steer clear of strong substances or metal scrapers, since they harm the PVC outer over periods.

UYANG BELTING’s white PVC belts tolerate regular rinses, yet gentle soaps preserve the outer’s bend and halt quick decline.

Sanitation Practices For Food Processing

In food zones, wiping exceeds looks. Plans should align with output rounds, focusing extra on joins and sides.

Fabric belts need thoughtful drying post-wipe to prevent water hold. Good air circulation and quick dry spells maintain the outer steady and free of smells.

When Should You Perform Preventive Maintenance On PVC Conveyor Belts?

Preventive tending shines when tied to a firm timetable, not just visible flaws.

Scheduled Inspection Checkpoints

Every week, quick looks spot early erosion clues. Each month, examine path, pull, and outer state.

Noting these checks reveals trends. If erosion hits quicker than planned, it signals job mismatch or gear faults.

Early Detection Of Belt Wear Indicators

Minor splits, side unraveling, or outer shine shifts warn of strain. Tackling these promptly averts abrupt breakdowns amid busy output.

For patterned belts, fading hold signals trouble. If items begin to slide, it points to outer care or swap needs.

Record Keeping And Maintenance Logs

Logs let groups monitor belt output across time. This info aids smarter swap plans and cuts uncertainty.

For firms with several paths, solid notes standardize tending across varied conveyor units.

Conclusion

Maintaining PVC conveyor belts at peak form blends wise picks, routine tending, and set upkeep. UYANG BELTING provides PVC belt answers tailored for steady output in food handling, wrapping, and basic transport jobs.

Through fitting the ideal belt to the role and sticking to steady wiping habits, firms extend belt spans, cut pauses, and ensure smooth runs daily.

FAQs

Q1: How long can a PVC conveyor belt last with proper maintenance?

A: With fitting choices and steady care, PVC conveyor belts run dependably for multiple years, based on weight, surroundings, and wipe frequency.

Q2: Are white PVC conveyor belts suitable for food processing lines?

A: Yes. Food-grade white PVC belts see broad use in food transport and wrapping thanks to their neat look, simple wiping, and opposition to typical food leftovers.

Q3: What is the main cause of early PVC conveyor belt failure?

A: Top reasons include wrong belt picks, weak wiping habits, and fixed off-center or pull troubles.