Smooth, clean, and steady movement is the core of every chocolate production line. From tempering to cooling and packaging, each step counts. In a setting where cleanliness and running time decide success, picking the right conveyor belt can make or break your operation. It might lead to perfect runs. Or it could cause stops, waste, and risks of dirt.

That’s where positive drive homogeneous belts come in. They use modern polymer tech and solid build. These belts are changing how chocolate gets moved, cooled, and packed. Firms like UYANG BELTING, a worldwide maker with more than 20 years in conveyor fixes, lead this shift. They offer new designs made for food making.

Why Is Hygiene Critical in Chocolate Conveying Systems?

In chocolate making, cleanliness is more than just rules. It’s a way to ensure quality. Even a tiny leftover can ruin flavor. Or it might set off dirt alerts. Conveyor systems often face this issue head-on.

Old fabric belts soak up water, sugar, and fats. Over time, they get small cracks. These are hard to clean well. That’s where homogeneous easy-to-clean belts set a new level.

Superior Sanitation with Homogeneous Structure

UYANG’s homogeneous belts come from TPU (Thermoplastic Polyurethane) or TPE (Thermoplastic Elastomer). They have no fabric part and no hidden spots. The firm, solid body stops germ hides. It lets fast, good washdowns. You can use high-pressure water or steam.

Fast Cleaning Reduces Downtime

The surface does not soak things. It fights oil or water. So, cleaning takes minutes, not hours. That gives more making time. It uses fewer chemicals. And it cuts water use. This is a clear gain for cleanliness and cost handling.

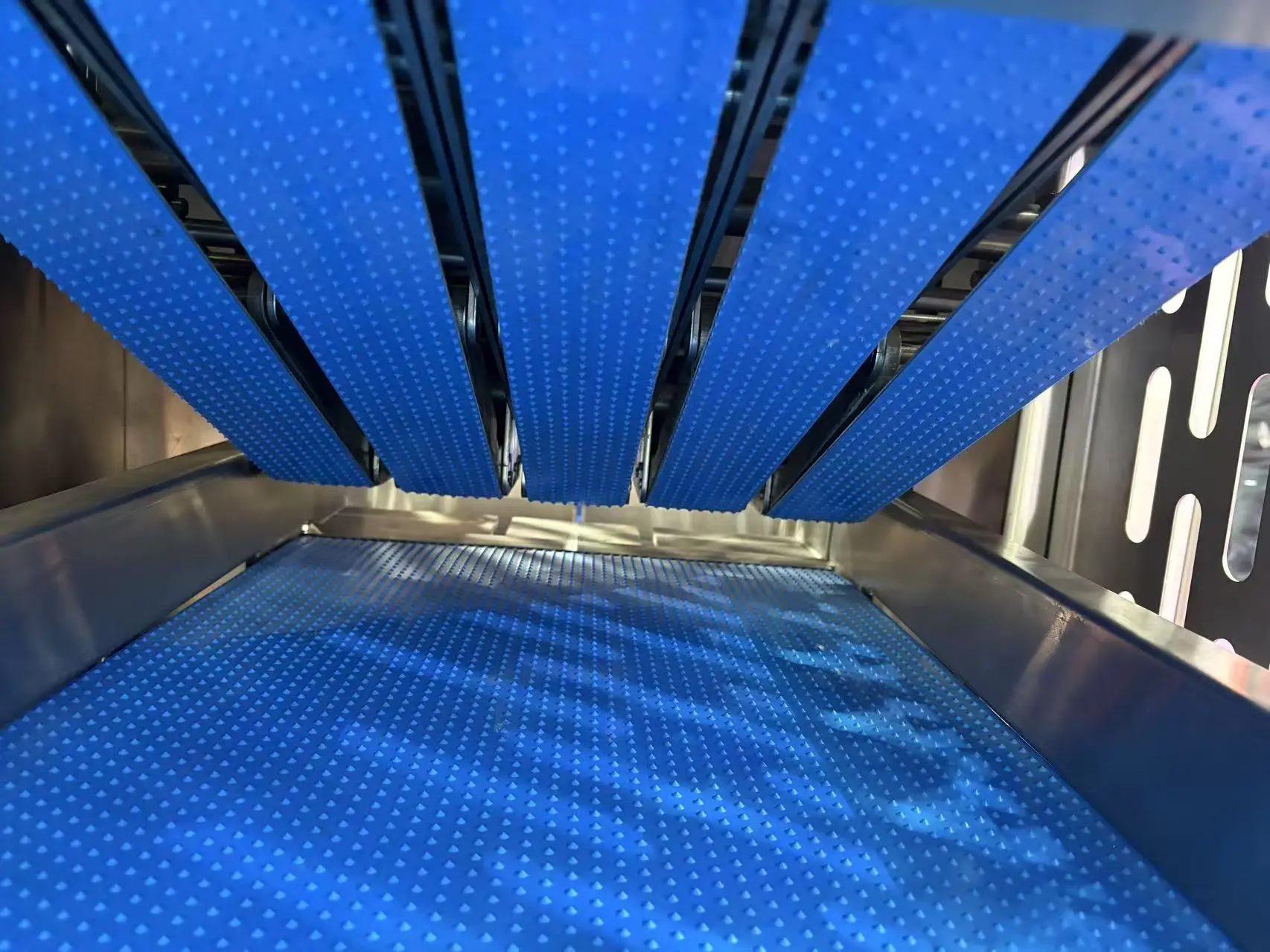

UYANG BELTING K00 Small Triangle Top for Chocolate Lines

The K00 Easy to Clean Homogeneous Belt with Small Triangle Top has a fine tiny pattern. It stops chocolate bits from sliding. But it does not harm soft coatings. It works well for transfer or shaping parts. It mixes cleanliness and hold in one simple, nice design.

How Do Positive Drive Belts Improve Energy Efficiency?

Power use in chocolate lines adds up quick. This happens with long conveyors and non-stop work. Losses from rub, pulling, and belt slide waste extra power. Positive drive belts fix this by their build.

Direct Drive Eliminates Slippage

They do not count on rub. Positive drive belts use shaped teeth. These lock right into sprockets. Each move stays in sync. This keeps speed even. And it cuts power waste to almost none.

Reduced Friction and Maintenance

With no pulling rollers or fabric parts, the drive runs cooler. It stays cleaner too. Less stretch means fewer fixes. And a longer life. For chocolate plants that run all day, this means fewer stops.

UYANG BELTING K40 Positive Drive Series for Continuous Flow

The Easy-to-Clean Positive Drive Homogeneous Belt – K40 Series is made for tough making settings. It gives a strong, steady drive. This works even in high wet or cool-room heat. The design helps keep exact flow control. This is key for even chocolate cooling. And for good packaging lines.

What Role Does Belt Surface Design Play in Chocolate Handling?

The belt’s top is not just for show. It affects product feel, cooling speed, and how clean pieces leave the line.

Gentle Transfer Protects Chocolate Surface

A even, same top stops soft truffles, bars, or pralines from getting marks or dents. That’s vital in top sweets making. There, looks matter as much as taste.

Optimal Grip Ensures Stability

Top shape counts. Fine patterns like golf or triangle help control hold in spots where chocolate is still soft or oily. The right hold keeps pieces straight through wrapping or checks. And it avoids leftover buildup.

UYANG BELTING K00 Golf Top for Packaging Zone

The Easy-to-Clean Homogeneous Belt K00 Series – Golf as Top has small round dips. These balance hold and let-go just right. In packaging spots, where small bars move fast, it stops slides. And it helps exact placing.

How Does Easy Cleaning Reduce Operational Costs?

A clean belt is not just for safety. It’s about money too. Stops for cleaning can cost lots per hour. Homogeneous belts cut those breaks.

Shorter Cleaning Cycles, Lower Water Use

Their slick, non-stick top rinses clean in less time. This cuts water and power use. That helps firms meet green goals without extra cost.

Less Chemical Consumption

With no fibers or cracks to trap dirt, there’s less need for strong chemicals. That guards the product. It also helps the cleaning team and the world.

Longer Belt Lifespan and Lower Replacement Frequency

Unlike PU or PVC belts that peel or split, UYANG’s homogeneous models stay whole for years. Even with often cleaning, they fight wear, cuts, and germ attacks. This cuts total owning cost a lot.

How Can Material Innovation Support Food Safety Standards?

The chocolate field works under strict food safety rules. These come from FDA and EU 10/2011 to HACCP and USDA levels. Every touch surface must meet them.

Compliance with Global Food Regulations

UYANG’s belts fit these world rules. They offer full tracking from raw stuff to end product. That gives makers trust during checks or client looks.

Non-Toxic and Oil-Resistant TPU Materials

The TPU mix used fights cocoa butter and cleaning stuff. It’s non-toxic, no smell, and steady even in cold or hot process zones.

Proven Applications in Chocolate and Confectionery Industries

These belts run in lines for chocolate enrobing, bar cooling, and transfer conveyors around the world. They show that cleanliness and work can go together.

Why Should Chocolate Producers Choose UYANG BELTING?

More than two decades in conveyor work gives UYANG a strong lead. The firm, in Guangzhou, China, runs over 80,000 square meters of making space. It has 15 modern lines. Its items include modular belts, homogeneous belts, PVC/PU belts, and custom conveying systems.

Over 20 Years of Belt Manufacturing Experience

From food plants to tire factories, UYANG BELTING has given steady conveying fixes worldwide. Its team mixes material know-how with real factory facts.

Complete Solutions for Food-Grade Conveying

Beyond belts, UYANG helps clients with cutting, joining, and setup tools. It gives full project help, not just parts.

Focus on Innovation, Quality, and Service

Every belt gets tested for strength, cleanliness, and long-term toughness. The firm’s service way has won trust across fields from Europe to Southeast Asia.

What Are the Key Takeaways for Chocolate Manufacturers?

Chocolate lines need exactness, cleanliness, and steadiness. Positive drive homogeneous belts meet all three. They give cleaner work, steadier motion, and longer-lasting work.

Enhanced Hygiene, Reduced Costs, Increased Output

Homogeneous build cuts germs, cleaning time, and power waste. It’s a straight upgrade for food safety and work performance.

UYANG BELTING as a Trusted Partner for Chocolate Production

With special belts like the K00 and K40 series, UYANG BELTING stands out. It’s a reliable partner for chocolate makers who want steady, clean, and good conveying systems.

FAQ

Q1: What makes a positive drive belt different from a traditional PU or PVC conveyor belt?

A: A positive drive belt uses molded teeth that fit into sprockets. This removes slippage and cuts tension. It also has a solid, fabric-free design. That’s easier to clean and more hygienic for food processing.

Q2: Can UYANG’s homogeneous belts handle both cooling and warm processing zones?

A: Yes. TPU and TPE materials work well from freezing to high-temperature spots. This makes them good for tempering, enrobing, and cooling parts.

Q3: How often do these belts need replacing?

A: In normal chocolate production conditions, UYANG’s homogeneous belts can last several years. Their solid construction prevents delamination. This gives a much longer lifespan compared to conventional multilayer belts.