In the quick-moving world of chocolate making, keeping things running smooth while making sure the product stays good is a big test. From mixing to packing, chocolate work needs a steady flow of stuff, good control of heat, and care in each part. One main thing that helps make this work well is the conveyor belt setup. These belts do more than just move chocolate through steps. They also boost cleanliness, cut down on trash, and raise output overall.

This piece looks at how special conveyor belts, like those from UYANG BELTING, are changing chocolate lines. They fix usual problems and give ways that raise speed, keep quality, and cut running costs.

The Complex World of Chocolate Production

Chocolate making is a tough job. Each part—from working on cocoa beans to shaping the end item—needs close watch and exact work. The parts include:

- Mixing and Refining: Raw things like cocoa, sugar, and milk get mixed and ground to make a smooth paste.

- Conching: The mix gets worked more to make the feel and taste better.

- Tempering: This makes sure the chocolate keeps its shiny look and crisp break.

- Molding and Cooling: Chocolate gets formed into bars or shapes and cooled to harden.

- Packaging: The end item gets wrapped for sending.

In all these parts, keeping the product safe, controlling heat, and stopping dirt are key. This is where good conveyor belts come in big.

The Role of Conveyor Belts in Chocolate Production

Conveyor belts are the heart of today’s chocolate lines. These setups make sure stuff moves steady between each work part, and they cut the need for hand work. As chocolate goes through different steps, from mixing to packing, the belt has to support ongoing motion without hurting the item’s quality.

A belt’s stuff, shape, and top design matter a lot for handling soft items like chocolate. You need belts that can handle heat, wet, and oils while keeping things clean.

Challenges in Chocolate Manufacturing and How Conveyor Belts Solve Them

Makers face many tests when picking the right conveyor for chocolate work. Old belts often have trouble with things like:

- Cleanliness Worries: Chocolate work deals with sticky, oily stuff. Many old belts are tough to wash and can get dirty easy.

- Heat Sensitivity: Chocolate needs exact heat in some parts, like tempering and cooling. A belt that can take strong heat without breaking down is needed.

- Steady Stuff Flow: To keep things fast, chocolate must slide smooth on the belt. Bad design can cause waits or harm to items.

With special PU conveyor belts, makers can beat these problems. They make the work quicker and cleaner.

How Conveyor Belts Drive Efficiency in Chocolate Production

Conveyor belts, mainly those made of strong, good-working stuff like polyurethane (PU), are built to fit the special needs of food and drink work. Here’s how they boost speed in chocolate making:

Boosting Item Flow and Line Steady

The main job of a conveyor belt is to shift items from one work part to the next. But it’s not only about moving chocolate from spot A to spot B. The belt must make sure the item keeps its shape and heat all through. A good belt setup cuts stops between parts. It makes a smooth flow.

Boosting Cleanliness and Food Safety

PU conveyor belts stand up well to oils, sugars, and wet—usual things in chocolate work. These belts are made to wash easy, cutting the chance of dirt. Steady wash times are key in food work. A belt that can take many washes without wearing out is great for keeping food safe rules.

Making Cooling and Heat Control Better

In molding and cooling parts, keeping a steady heat is key. Belts with strong heat stand, like those from UYANG BELTING, can take changing heats in cooling paths without losing strength. These belts help air move right. They make sure chocolate hardens well, with even cooling in the whole group.

The UYANG BELTING Solution for Chocolate Production

UYANG BELTING makes top PU conveyor belts for the chocolate field. Their items have new top designs that give extra help for chocolate makers.

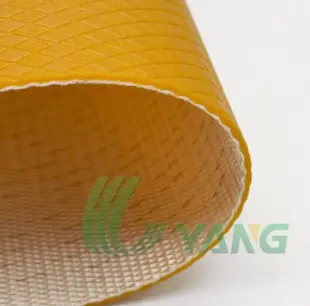

PU Conveyor Belt – Convex Rhombus Pattern Top

The Convex Rhombus Pattern is made special for chocolate lines to cut item stick and stop chocolate from clinging to the belt. This odd top design makes sure chocolate shifts smooth and cuts wash stops a lot. It can take high heats and hard use. So, it fits well for cooling and coating parts in chocolate work.

With the Convex Rhombus Pattern belt, chocolate makers can get better output, less item trash, and shorter wash times. These belts are not only tough but also simple to keep. They help long-run speed.

PU Conveyor Belt – Harkqui Pattern Top

The Harkqui Pattern Top belt is one more good pick for chocolate work. Its shape aims to give more hold for items that might need extra back, like in shaping and packing. The strong wear stand and toughness of this belt make sure steady work over long runs. It cuts the chance of item slide or change in shape.

The Harkqui Pattern Top works well in spots where exact and steady are most important, like in lining up shapes and steady placing of wrapped items. This design also cuts belt pull and gives better rule over chocolate flow.

Integrating UYANG BELTING into Chocolate Production Lines

Putting UYANG BELTING’s PU conveyor belts into chocolate lines can happen easy, even in old setups. UYANG BELTING gives custom sizes and edge ends to make sure they fit with different conveyor setups. Their items are built to take the needs of big-volume lines while giving the work needed to handle soft chocolate items.

When picking the right belt, think about things like work speed, heat control needs, and the kind of chocolate made. UYANG BELTING’s pros can help makers pick the best belt shape for their exact work needs.

The Future of Conveyor Systems in Chocolate Production

As the chocolate field grows, so does the need for better conveyor setups. Auto work and smart watch tools are starting to change how conveyor setups run. They make it simpler to follow belt work, watch heat, and make sure item quality right then.

The future of belts in chocolate work is in making greener ways, with nature-friendly stuff and power-saving shapes. Plus, the want for belts that fit well with new auto setups is set to rise. This lets chocolate makers boost output even more.

Conclusion: Building High-Performance Chocolate Production Lines

Conveyor belts are more than a basic tool in chocolate work. They play a big part in making sure the work runs smooth, clean, and quick. With UYANG BELTING’s special PU conveyor belts, chocolate makers can get better output, better cleanliness, and fewer stops. This leads to money saves and better item quality.

By picking the right belt, makers not only make their work lines better but also set them up for changes in a growing field.

FAQs

Q1: How do PU conveyor belts improve efficiency in chocolate production?

A: PU conveyor belts, such as those with Convex Rhombus and Harkqui patterns, are designed to minimize product adhesion, withstand high temperatures, and offer easy cleaning. These features reduce downtime, improve throughput, and ensure consistent product quality.

Q2: Can UYANG BELTING’s conveyor belts be used in existing chocolate production lines?

A: Yes, UYANG BELTING’s conveyor belts can be easily integrated into existing production lines. They offer custom dimensions and edge finishing options to ensure compatibility with various systems.

Q3: What makes UYANG BELTING’s conveyor belts different from traditional belts?

A: UYANG BELTING’s conveyor belts are made from high-quality polyurethane that resists oils, sugars, and moisture, making them ideal for food production. Their surface patterns are designed to improve grip, reduce product slippage, and enhance cooling efficiency, ensuring better performance than traditional belts.