The UYANG High Frequency Welding Machine is designed for welding cleats, guides, and sidewalls onto PVC and PU conveyor belts using high-frequency electromagnetic heating.

This process creates strong, uniform, and permanent bonds without adhesives, making it ideal for producing profiled and functional conveyor belts for demanding industrial applications.

The UYANG High Frequency Welding Machine is designed for welding cleats, guides, and sidewalls onto PVC and PU conveyor belts using high-frequency electromagnetic heating.

This process creates strong, uniform, and permanent bonds without adhesives, making it ideal for producing profiled and functional conveyor belts for demanding industrial applications.

High-frequency welding of belt accessories

Attaching cleats, guides, and sidewalls to conveyor belts

Creating integrated belt structures with high bonding strength

Cleats for inclined and horizontal conveying

Guide profiles for belt tracking and positioning

Sidewalls / skirts for material containment

High-frequency electromagnetic welding technology

Strong molecular-level bonding for PVC & PU materials

Clean welding process without glue or solvents

Stable welding quality with good repeatability

Suitable for workshop and production environments

| Item | Description |

| Application | PVC & PU conveyor belts |

| Welding method | High frequency (HF) welding |

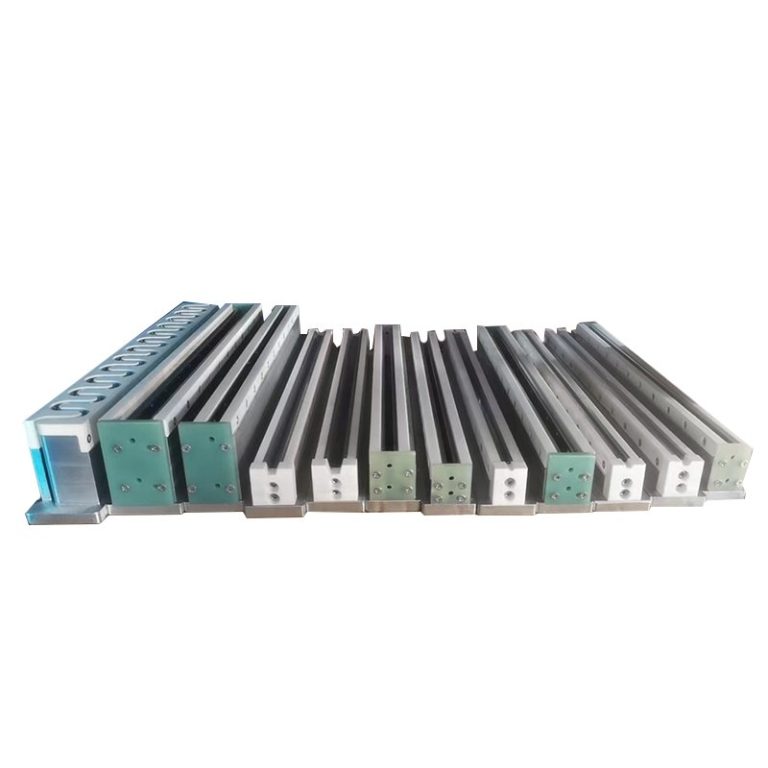

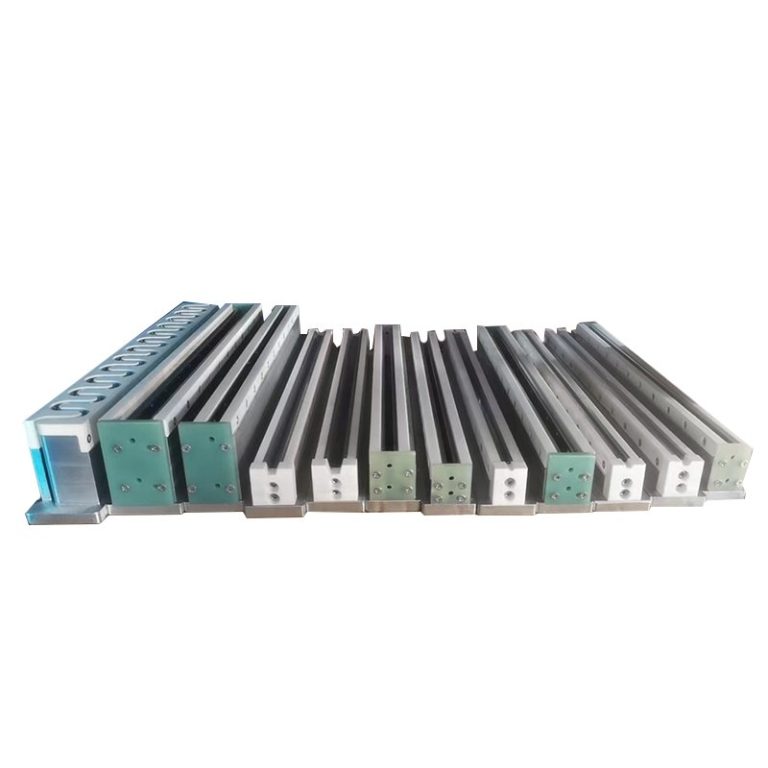

| Welded components | Cleats, guides, sidewalls |

| Operation mode | Manual / Semi-automatic |

| Heating principle | High-frequency electromagnetic field |

| Installation | Workshop / Factory floor |

Machine configuration and tooling can be customized according to belt type and profile design.

Food processing conveyors

Packaging and logistics systems

Airport baggage handling

Inclined conveying systems

Customized conveyor belt fabrication

Strong and durable welded joints

Consistent quality for repetitive production

No adhesive aging or delamination risk

Enables functional belt customization

Different welding power levels

Tooling matched to cleat, guide, or sidewall profiles

Worktable size adapted to belt width

Electrical configuration for different regions

Operated by trained personnel only

High-frequency area should be properly shielded

Ensure correct tooling alignment before welding

Regular inspection of electrical and welding components recommended

UYANG BELTING

Light-duty Conveyor Belt & Processing Solution Provider

Reliable delivery schedules and warehousing support.

Competitive pricing to maximize overall value.

Diverse options to cater to all market segments.

Flexible MOQ Support with all types of goods;

Personalized logo customization on the products

Provide online technical support for all product usage and installation processes

Quick first response to all inquiry and questions

Provide quality images, Video to enhance sales revenue

Efficient production and ship within 15 days at the fastest.

Generally it is 10-15 days, if peak season, it will be about 15-20 day safter receiving the deposit

1. Confirmed Specification: thickness,color, plies,characteristic, and industry;

2. Samples sending: we send samples for you check.or you send us samples if customized belt.

3. Confirm Order: Signing sales contract after samples confirmed.

4. Deposit: 30% deposit before mass production.

5. Production arranged : we will process the production.

6. Remaining payment: after inspection, balance before shipment.

7. Shipping: we will ship the goods to destination port.

8. Confirm bill of loading/commercial invoice/packing list/certificate of origin;