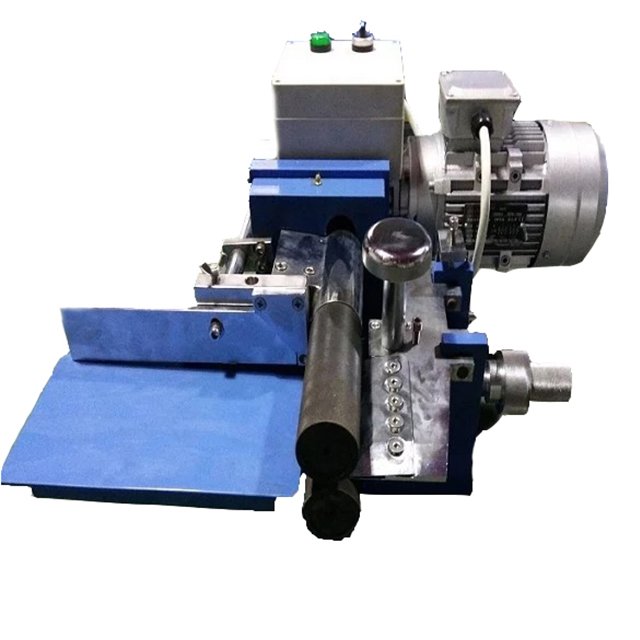

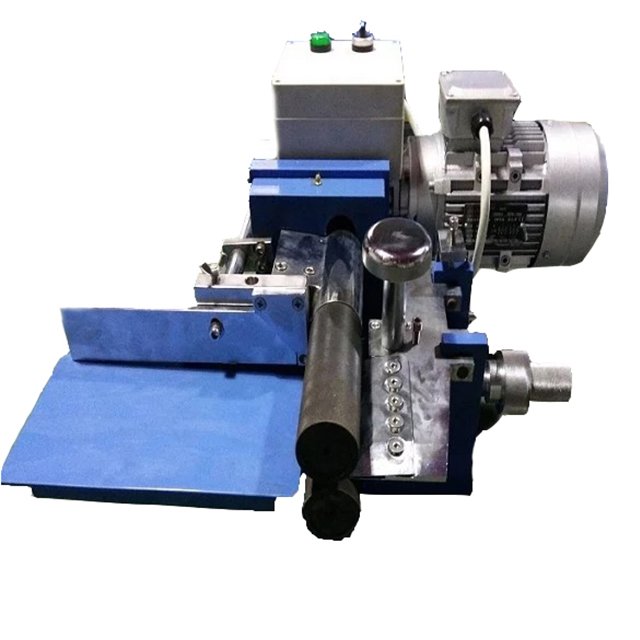

The UYANG Conveyor Belt Ply Separator is designed to separate fabric plies of PVC and PU conveyor belts in a controlled and uniform manner.

It is widely used for belt joint preparation, allowing precise removal of belt layers before finger splicing, overlap splicing, or special joint processing.

By ensuring clean, even ply separation, the machine significantly improves joint quality and process consistency.

The UYANG Conveyor Belt Ply Separator is designed to separate fabric plies of PVC and PU conveyor belts in a controlled and uniform manner.

It is widely used for belt joint preparation, allowing precise removal of belt layers before finger splicing, overlap splicing, or special joint processing.

By ensuring clean, even ply separation, the machine significantly improves joint quality and process consistency.

Separating conveyor belt fabric plies

Preparing belt ends for splicing operations

Creating uniform layer thickness for reliable joints

Stable separation mechanism

Ensures smooth and controlled ply separation without damaging belt fabric

Uniform separation depth

Provides consistent results across the entire belt width

Suitable for PVC & PU belts

Compatible with common light-duty conveyor belt constructions

Improves joint quality

Ensures accurate layer matching during splicing

Workshop-friendly design

Simple operation and reliable mechanical structure

Technical Datasheet:

| Minimum | Maximum | |

| Split width | 40mm | 130mm |

| Upper part belt split thickness | 0.5mm | 8mm |

| Lower part belt split thickness | 0.5mm | 5mm |

| Max belt thickness | – | 10mm |

Separation capacity and configuration depend on belt thickness and ply structure.

Conveyor belt finger joint preparation

Overlap joint preparation

Belt repair and refurbishment

Conveyor belt fabrication workshops

OEM belt processing lines

Clean and consistent ply separation

Reduced risk of uneven joint thickness

Improved splicing strength and durability

Higher repeatability compared with manual separation

Different effective working widths

Adjustment for various belt thicknesses

Custom configurations for specific belt constructions

Operated by trained personnel only

Ensure belt is properly aligned before separation

Do not force separation beyond belt design limits

Regular inspection of separation components recommended

UYANG BELTING

Light-duty Conveyor Belt & Processing Solution Provider

Reliable delivery schedules and warehousing support.

Competitive pricing to maximize overall value.

Diverse options to cater to all market segments.

Flexible MOQ Support with all types of goods;

Personalized logo customization on the products

Provide online technical support for all product usage and installation processes

Quick first response to all inquiry and questions

Provide quality images, Video to enhance sales revenue

Efficient production and ship within 15 days at the fastest.

Generally it is 10-15 days, if peak season, it will be about 15-20 day safter receiving the deposit

1. Confirmed Specification: thickness,color, plies,characteristic, and industry;

2. Samples sending: we send samples for you check.or you send us samples if customized belt.

3. Confirm Order: Signing sales contract after samples confirmed.

4. Deposit: 30% deposit before mass production.

5. Production arranged : we will process the production.

6. Remaining payment: after inspection, balance before shipment.

7. Shipping: we will ship the goods to destination port.

8. Confirm bill of loading/commercial invoice/packing list/certificate of origin;