The UYANG Belt Guide Welding Machine is a dedicated machine designed to weld V-guides (guide strips) onto PVC and PU light-duty conveyor belts.

It is widely used to improve belt tracking and positioning accuracy, especially in applications where precise belt guidance is required.

The machine adopts frequency inverter control, ensuring smooth operation, stable welding speed, and consistent guide alignment.

The UYANG Belt Guide Welding Machine is a dedicated machine designed to weld V-guides (guide strips) onto PVC and PU light-duty conveyor belts.

It is widely used to improve belt tracking and positioning accuracy, especially in applications where precise belt guidance is required.

The machine adopts frequency inverter control, ensuring smooth operation, stable welding speed, and consistent guide alignment.

Welding V-type guide strips onto PVC / PU conveyor belts

Ensuring accurate, parallel, and stable guide positioning

Supporting both open belts and endless belts

High working efficiency

Welding speed up to approx. 4 m/min

Frequency inverter control

Smooth speed adjustment and stable belt movement

Multiple guide mould options

Standard mould sizes: 6×4, 8×5, 10×6, 13×8 mm

Custom sizes available (e.g. 17×11 mm)

Horizontal & vertical adjustment system

Easy and precise positioning of the welding head

Endless belt compatibility

Suitable for both open belts and endless conveyor belts

Compact and mobile design

Small footprint, wheel-base structure for easy movement

No belt tension system or floor track required

Pause function without power-off

Allows controlled stopping during welding operations

Standard welding system: hot air gun (heat gun not included as standard)

Guide moulds are quick-changeable and can be customized

Optional grinding head for welding on the fabric side of the belt

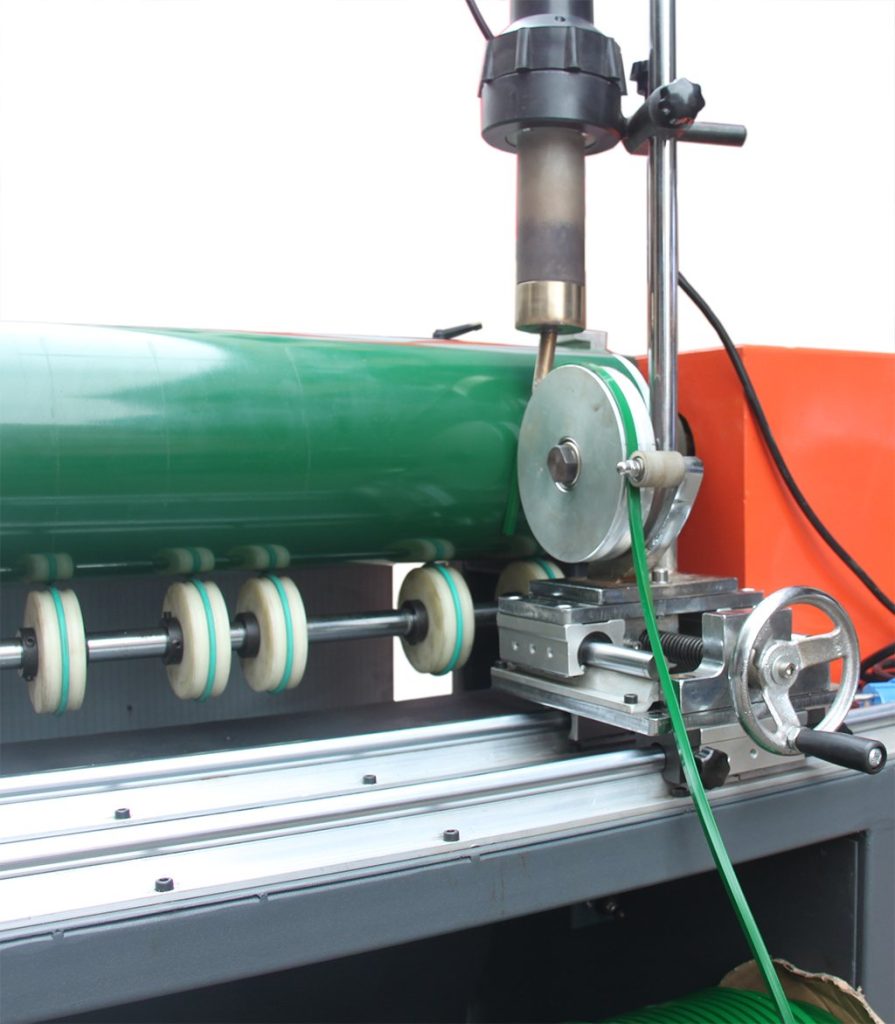

Machine frame

Motor

Frequency inverter

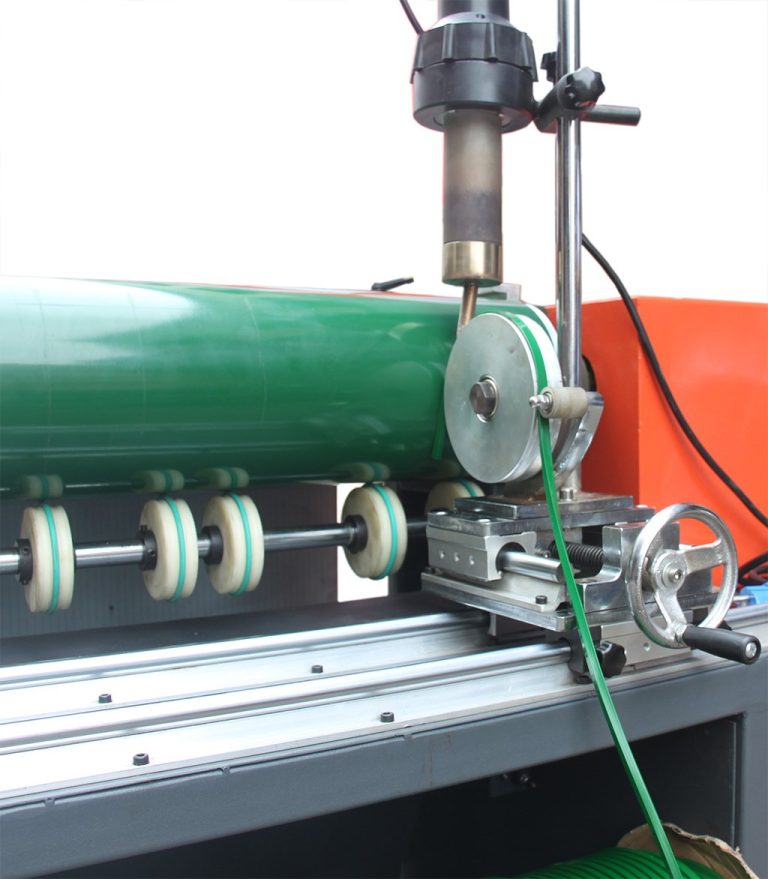

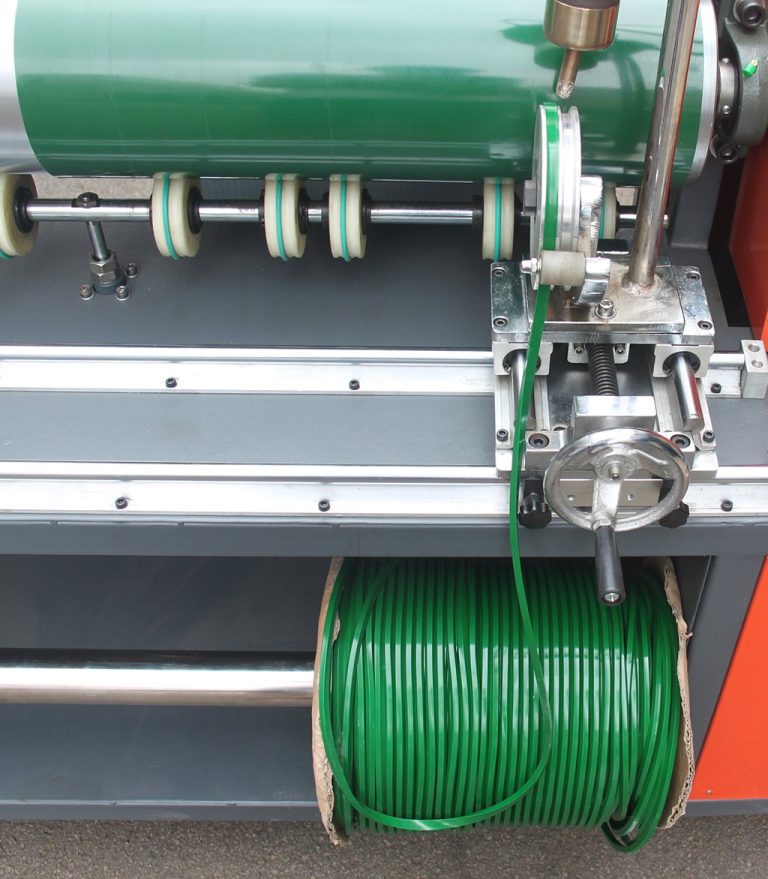

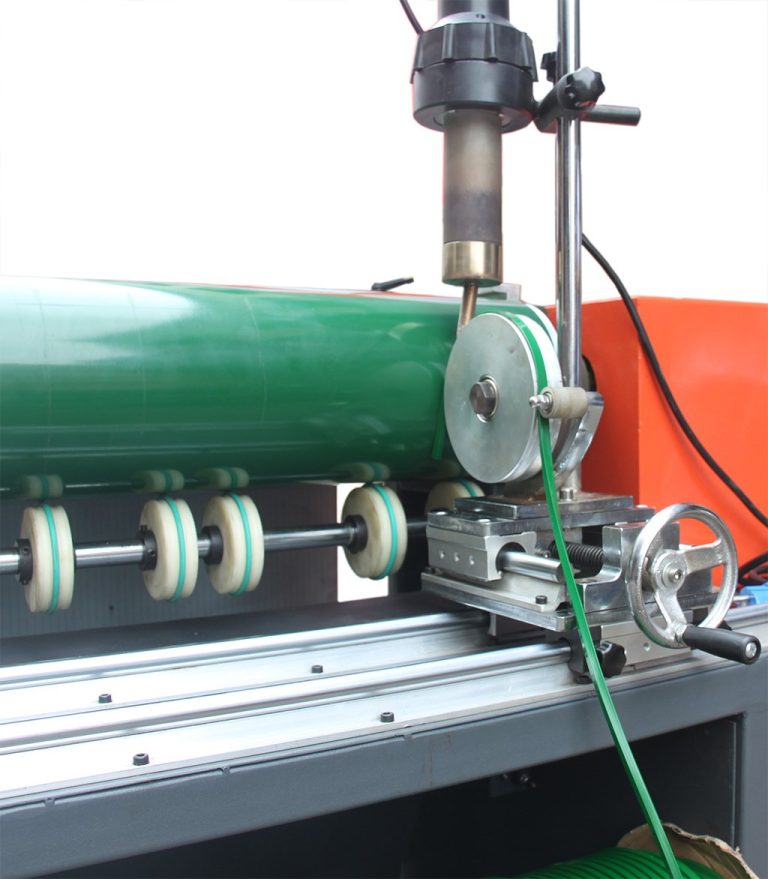

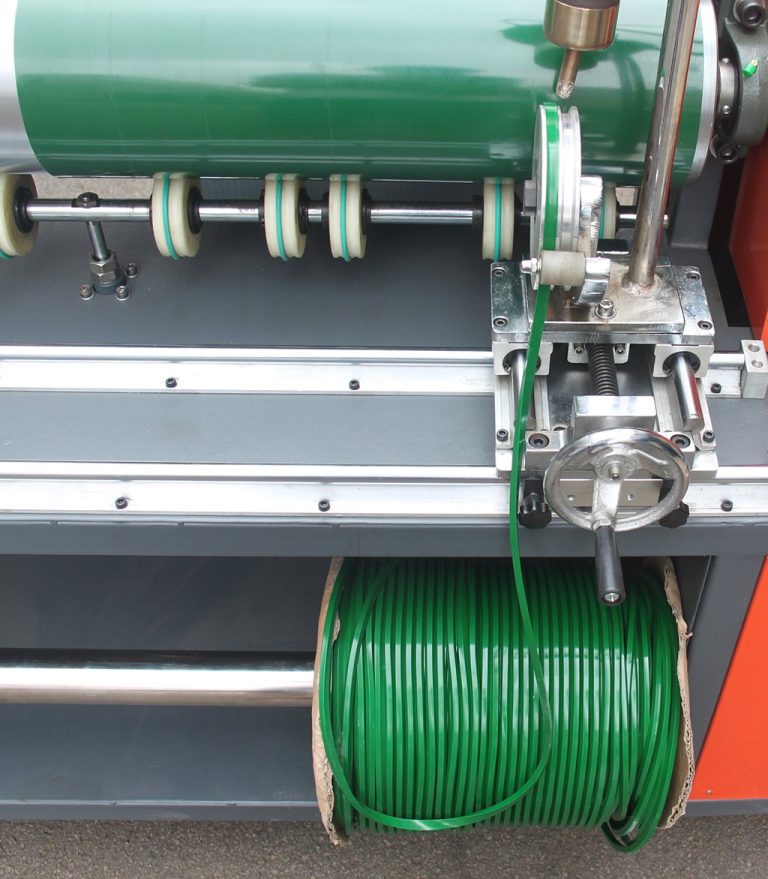

Drive rollers and guide pulleys

Press pulley

Worktable

Welding system

| Item | UY1400 | UY1600 |

|---|---|---|

| Machine length | 1400 mm | 1600 mm |

| Machine width | 660 mm | 660 mm |

| Machine height | 1350 mm | 1350 mm |

| Net weight | 180 kg | 200 kg |

| Packing weight | 226 kg | 270 kg |

| Packing size | 1540 × 760 × 1180 mm | 1740 × 760 × 1180 mm |

| Power | 550 W | 550 W |

| Max. drum speed | 4 m/min | 4 m/min |

| Working width of drum | 1000 mm | 1200 mm |

Guide wheels (e.g. 17×11 mm, 22×14 mm)

Grinding head (for belt surface preparation)

Heating gun holder (required when welding two guides simultaneously)

Hot air heating gun

Conveyor belts requiring precise tracking

Packaging and logistics conveyors

Food processing conveyors

Printing and light industrial systems

Customized profiled conveyor belts

UYANG BELTING

Light-Duty Conveyor Belt & Processing Equipment Provider

Reliable delivery schedules and warehousing support.

Competitive pricing to maximize overall value.

Diverse options to cater to all market segments.

Flexible MOQ Support with all types of goods;

Personalized logo customization on the products

Provide online technical support for all product usage and installation processes

Quick first response to all inquiry and questions

Provide quality images, Video to enhance sales revenue

Efficient production and ship within 15 days at the fastest.

Generally it is 10-15 days, if peak season, it will be about 15-20 day safter receiving the deposit

1. Confirmed Specification: thickness,color, plies,characteristic, and industry;

2. Samples sending: we send samples for you check.or you send us samples if customized belt.

3. Confirm Order: Signing sales contract after samples confirmed.

4. Deposit: 30% deposit before mass production.

5. Production arranged : we will process the production.

6. Remaining payment: after inspection, balance before shipment.

7. Shipping: we will ship the goods to destination port.

8. Confirm bill of loading/commercial invoice/packing list/certificate of origin;