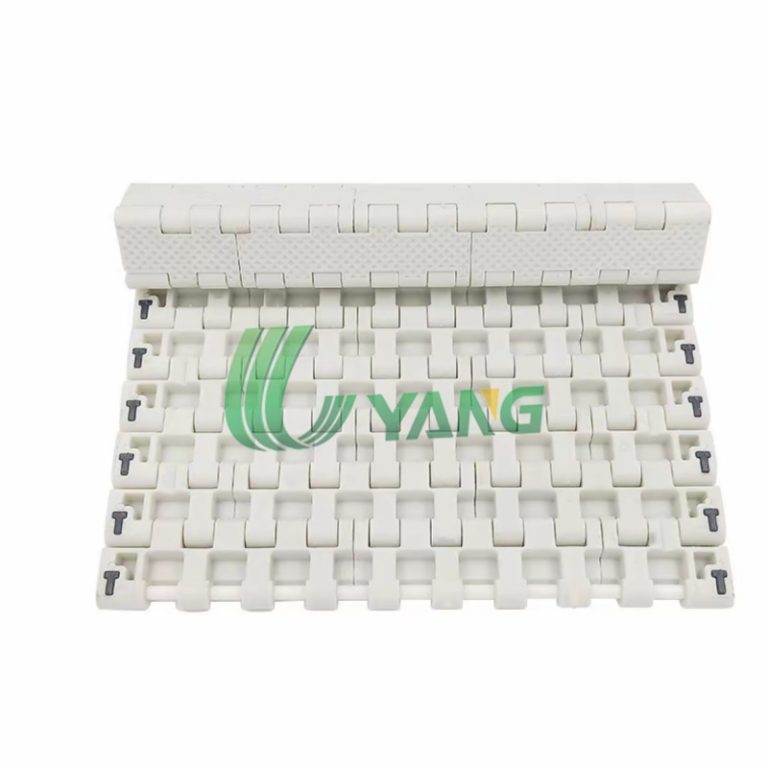

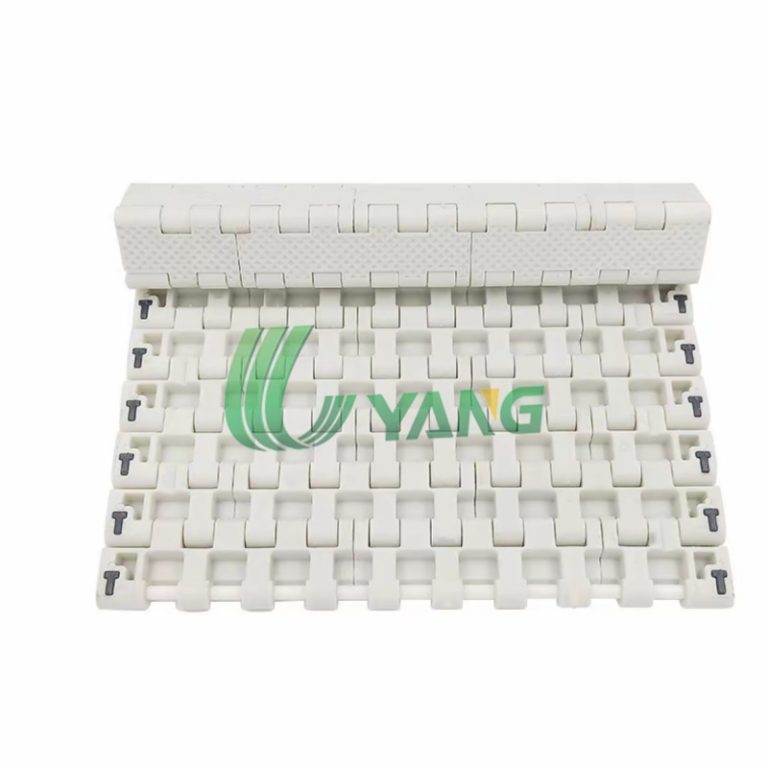

UY-25402A rhombic reticulated Modular Plastic Belt is designed for high-efficiency cooling and transfer in tire manufacturing lines. Made from durable PP or POM materials, it provides excellent strength, smooth operation, and long-lasting performance even under continuous heavy-duty use.

UY-25402A rhombic reticulated Modular Plastic Belt is designed for high-efficiency cooling and transfer in tire manufacturing lines. Made from durable PP or POM materials, it provides excellent strength, smooth operation, and long-lasting performance even under continuous heavy-duty use.

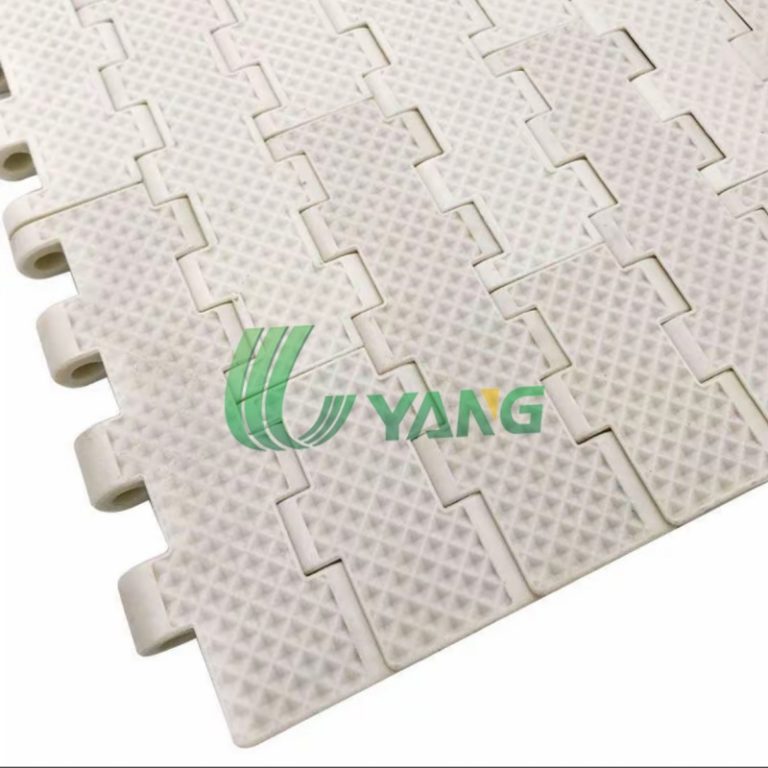

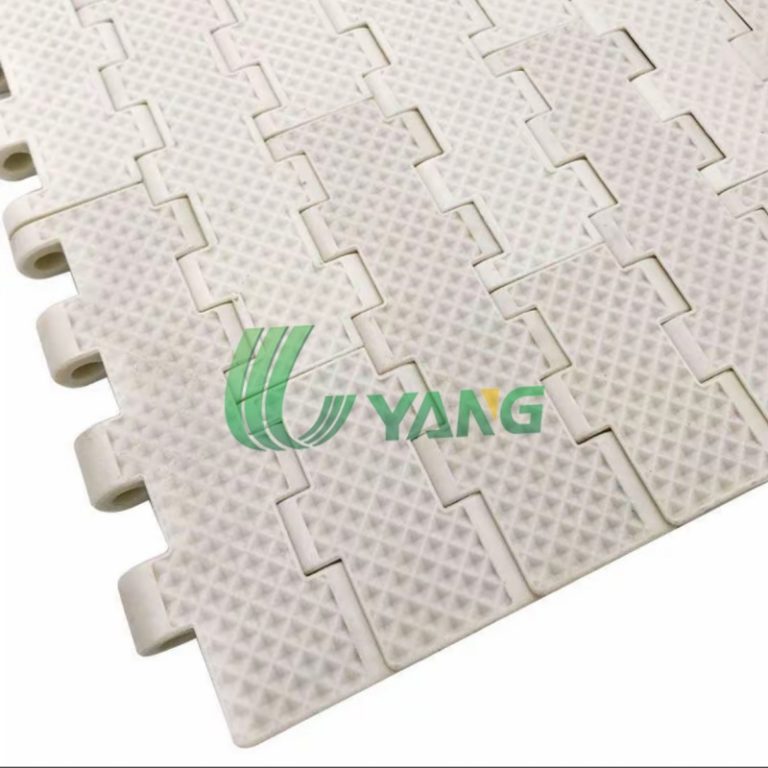

Rhombic open mesh for better air circulation

Strong PP/POM material for long service life

High tensile strength up to 40,200 N/m

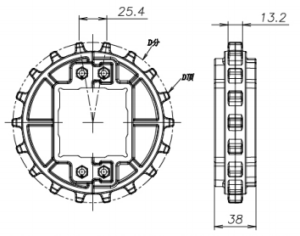

Smooth and stable conveying with 25.4 mm pitch

Easy modular installation and maintenance

The UY-25402A modular conveyor belt is built to handle the real demands of tire production.

In the cooling and transfer stages, it runs smoothly and stays stable even under heavy, continuous use. The rhombic open design improves airflow, helping tires cool evenly and efficiently. Made from high-quality PP or POM materials, it resists wear, handles weight well, and keeps downtime to a minimum — exactly what modern tire factories need.

Perfect for:

Tire cooling lines

Automotive component production

Industrial packaging conveyors

Cooling and drying sections in manufacturing

| Parameter | Description |

|---|---|

| Belt Material | PP / POM |

| Rod Material | PA / Metal |

| Pitch | 25.4 mm |

| Belt Width (per module) | 101 mm |

| Operating Load (21°C) | up to 40,200 N/m |

| Open Area | 0% |

| Applications | Tire cooling, drying, industrial transfer |

| Spec |

Number of Teeth |

Bore Diameter (mm) | Pitch Diameter |

Outer Diameter |

Forming Way |

|

|---|---|---|---|---|---|---|

| Round | Square | |||||

| 25402-12T | 12 | 30–40 | 38.1-40 | 3.9″ / 99 mm | 3.9″ / 99 mm | Injection molding |

| 25402-18T | 18 | 30–40 | 40-60 | 5.1″ / 145 mm | 5.83″ / 148 mm | Injection molding |

| 25402-20T | 20 | 30–40 | 40-60 | 6.4″ / 162 mm | 6.41″ / 163 mm | Injection molding |

Other tooth numbers can be customized.

Shaft hole can be square or round, depending on customer requirements.

Plastic sprockets are available in POM / PP / PA.

Machined sprockets can be made from PA / PP.

With years of experience in modular conveyor systems, UYANG BELTING delivers belts that combine strength, flexibility, and efficiency. Each product is tested for durability and performance, ensuring consistent operation under demanding industrial conditions.

Reliable delivery schedules and warehousing support.

Competitive pricing to maximize overall value.

Diverse options to cater to all market segments.

Flexible MOQ Support with all types of goods;

Personalized logo customization on the products

Provide online technical support for all product usage and installation processes

Quick first response to all inquiry and questions

Provide quality images, Video to enhance sales revenue

Efficient production and ship within 15 days at the fastest.

Generally it is 10-15 days, if peak season, it will be about 15-20 day safter receiving the deposit

1. Confirmed Specification: thickness,color, plies,characteristic, and industry;

2. Samples sending: we send samples for you check.or you send us samples if customized belt.

3. Confirm Order: Signing sales contract after samples confirmed.

4. Deposit: 30% deposit before mass production.

5. Production arranged : we will process the production.

6. Remaining payment: after inspection, balance before shipment.

7. Shipping: we will ship the goods to destination port.

8. Confirm bill of loading/commercial invoice/packing list/certificate of origin;