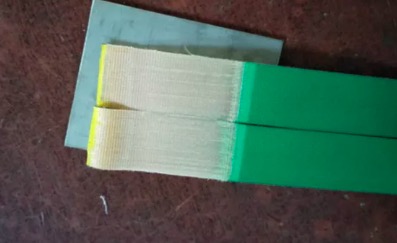

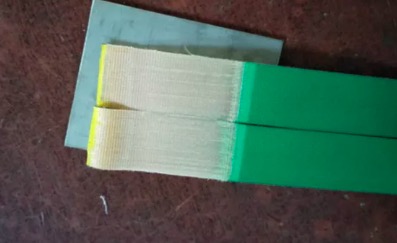

Prepare belt ends for perfect splicing. UYANG BELTING Transmission Belt Butt-End Grinding Machine professionally grinds and profiles the joint ends of transmission belts so they mate cleanly and form a seamless loop — ideal for production lines and repair shops that require fast, repeatable, high-strength belt joints.

Prepare belt ends for perfect splicing. UYANG BELTING Transmission Belt Butt-End Grinding Machine professionally grinds and profiles the joint ends of transmission belts so they mate cleanly and form a seamless loop — ideal for production lines and repair shops that require fast, repeatable, high-strength belt joints.

Precise End Finish

Stronger Joints

Fast Prep

Easy Alignment

Wide Compatibility

Clean Operation

| Item | Product | Type | Photo | Description | PACKAGE |

| Advantage: Profile frame, Meticulously crafted, smooth operation, even grinding, precise thickness, convenient operation, adjustable grinding head slope within a specific length range. | |||||

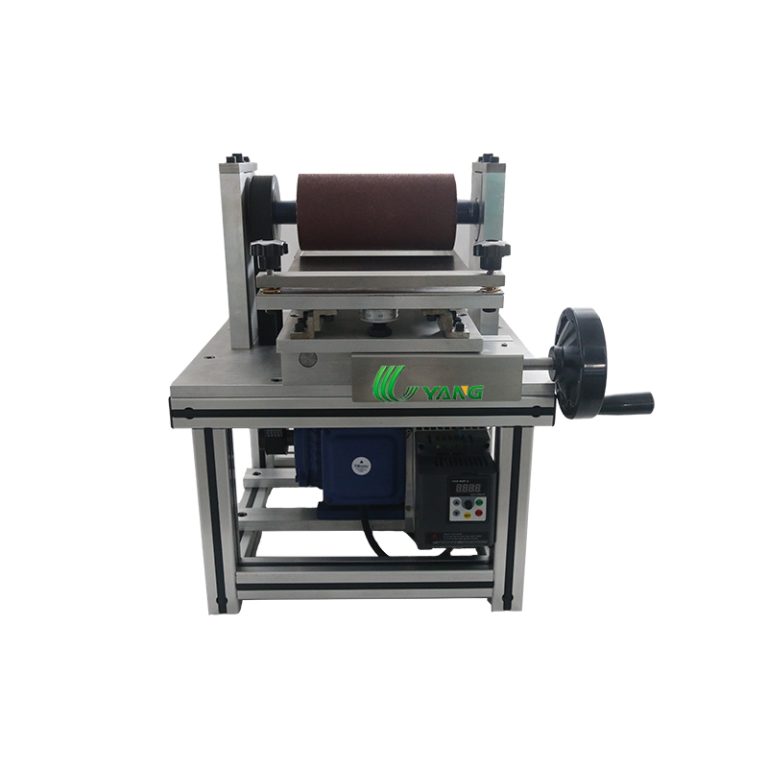

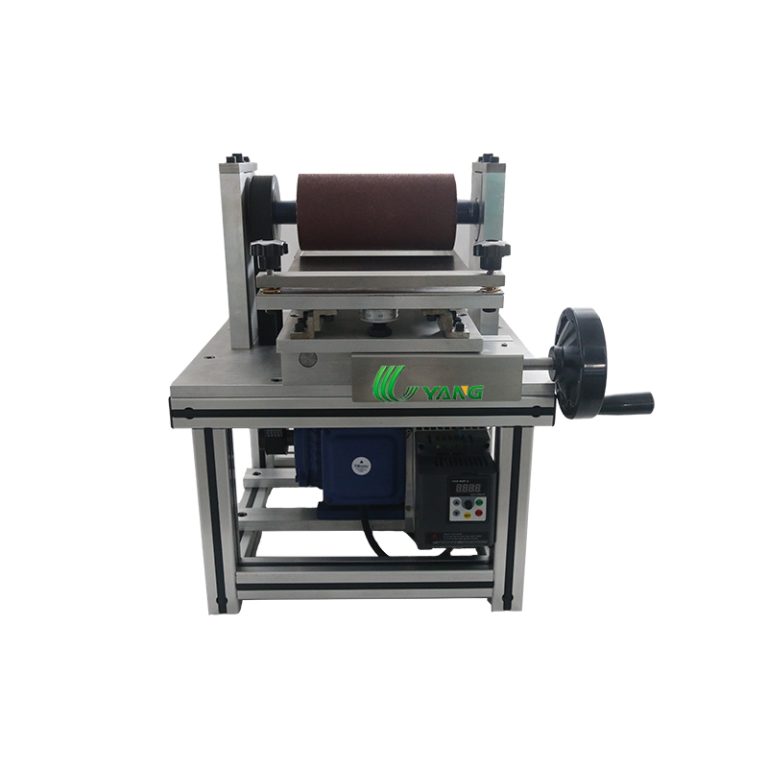

| 1 | Grinder | UY-MT-1015 |  |

Grinder: Performance Parameters: 1. Voltage: 220V 2. Manual Push 3.Sanding Belt Grinding Drum 4. Max Grinding Length: 100mm; 5. Max Grinding Width: 150mm 7.Application: suitable for Chip base belt |

NW: 35kgs; GW:46kgs; PACKAGE: 480*480*600mm |

| 2 | Grinder | UY-MT-1320 |  |

Grinder: Performance Parameters: 1. Voltage: 220V 2. Manual Push 3.Sanding Belt Grinding Drum 4. Max Grinding Length: 130mm; 5. Max Grinding Width: 200mm 7.Application: suitable for Chip base belt |

NW: 57kgs; GW:72kgs; PACKAGE: 560*490*680mm |

| 3 | Grinder | UY-MT-1530 |  |

Grinder: Performance Parameters: 1. Voltage: 220V 2. Variable Frequency Motor 3. Manual Push 4.Sanding Belt Grinding Drum 5. Max Grinding Length: 150mm; 6. Max Grinding Width: 300mm 7.Application: suitable for Chip base belt |

NW: 100kgs; GW:129kgs; PACKAGE: 660*590*780mm |

| 4 | Grinder | UY-MT-1540 |  |

Grinder: Performance Parameters: 1. Voltage: 220V 2. Variable Frequency Motor 3. Manual Push 4.Sanding Belt Grinding Drum 5. Max Grinding Length: 150mm; 6. Max Grinding Width: 400mm 7.Application: suitable for Chip base belt |

NW: 130kgs; GW:150kgs; PACKAGE: 690*660*780mm |

| 5 | Grinder | UY-MT-1550 |  |

Grinder: Performance Parameters: 1. Voltage: 220V 2. Variable Frequency Motor 3. Manual Push 4.Sanding Belt Grinding Drum 5. Max Grinding Length: 150mm; 6. Max Grinding Width: 500mm 7.Application: suitable for Chip base belt |

NW: 145kgs; GW:175kgs; PACKAGE: 790*660*780mm |

| 6 | Grinder | UY-MT-1560 |  |

Grinder: Performance Parameters: 1. Voltage: 220V 2. Variable Frequency Motor 3. Manual Push 4.Sanding Belt Grinding Drum 5. Max Grinding Length: 150mm; 6. Max Grinding Width: 600mm 7.Application: suitable for Chip base belt |

NW: 159kgs; GW:190kgs; PACKAGE: 890*660*780mm |

| 7 | Grinder | UY-MT-600A | Grinder: Performance Parameters: 1. Voltage: 380V 2. Max Grinding Length: 130mm; 3. Max Grinding Width: 600mm; 4.CNC (Computer Numerical Control) Fully Automatic; 5. Sandblasting Grinding Drum, Durable and Long-lasting 6.Application: suitable for Chip base belt |

||

Reliable delivery schedules and warehousing support.

Competitive pricing to maximize overall value.

Diverse options to cater to all market segments.

Flexible MOQ Support with all types of goods;

Personalized logo customization on the products

Provide online technical support for all product usage and installation processes

Quick first response to all inquiry and questions

Provide quality images, Video to enhance sales revenue

Efficient production and ship within 15 days at the fastest.

Generally it is 10-15 days, if peak season, it will be about 15-20 day safter receiving the deposit

1. Confirmed Specification: thickness,color, plies,characteristic, and industry;

2. Samples sending: we send samples for you check.or you send us samples if customized belt.

3. Confirm Order: Signing sales contract after samples confirmed.

4. Deposit: 30% deposit before mass production.

5. Production arranged : we will process the production.

6. Remaining payment: after inspection, balance before shipment.

7. Shipping: we will ship the goods to destination port.

8. Confirm bill of loading/commercial invoice/packing list/certificate of origin;