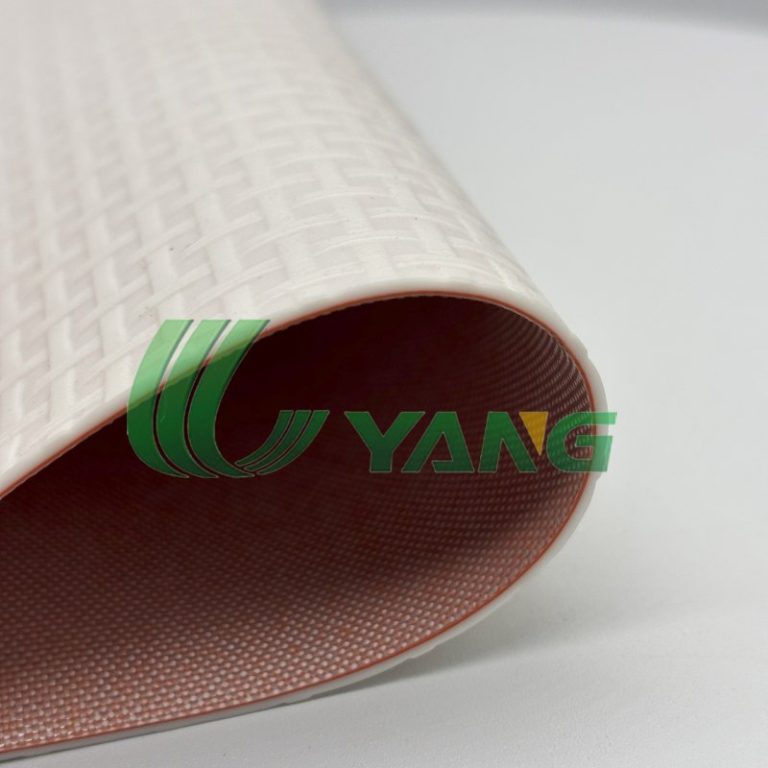

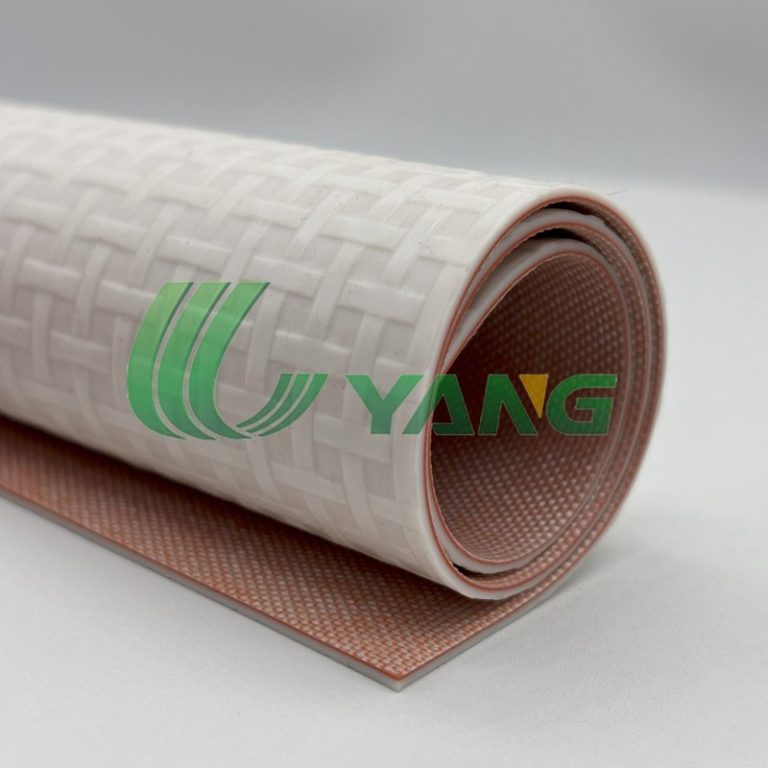

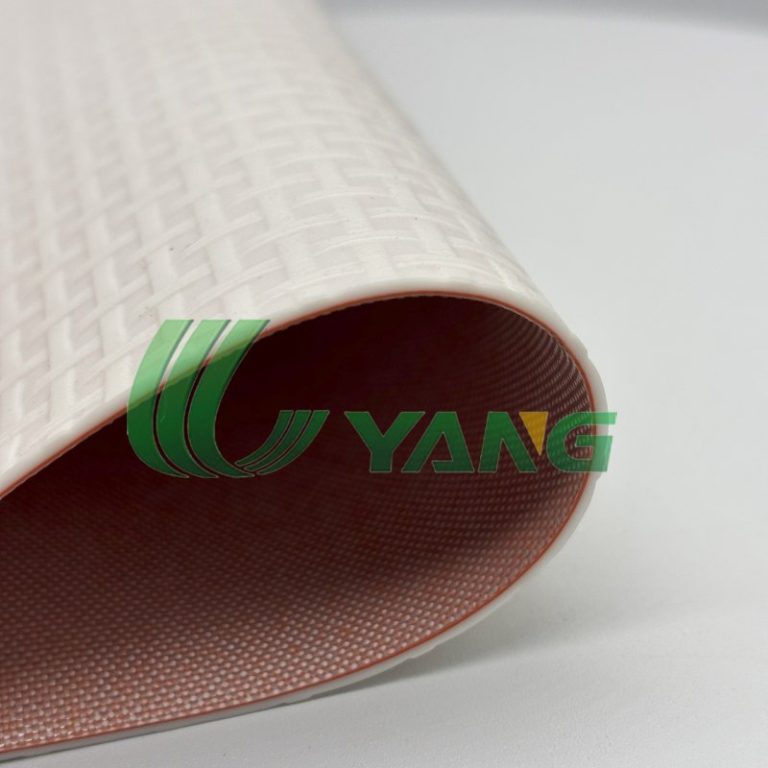

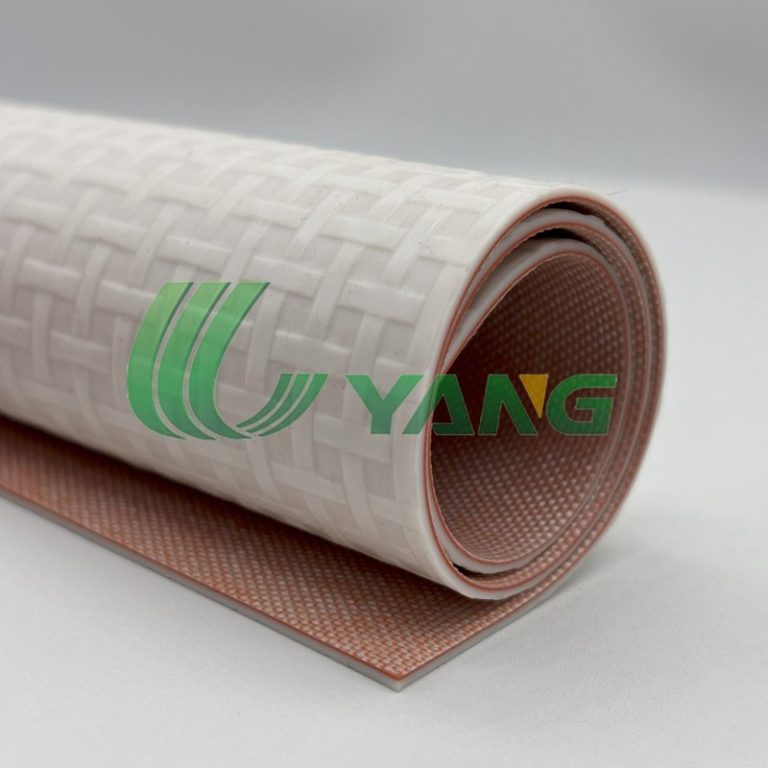

Specially designed for joining patterned conveyor belts (e.g., cross-lattice, herringbone, diamond grooves) during hot vulcanization or cold bonding. The silicone mold ensures the original texture is preserved at the splice area, avoiding distortion or flattening caused by rigid molds.

Specially designed for joining patterned conveyor belts (e.g., cross-lattice, herringbone, diamond grooves) during hot vulcanization or cold bonding. The silicone mold ensures the original texture is preserved at the splice area, avoiding distortion or flattening caused by rigid molds.

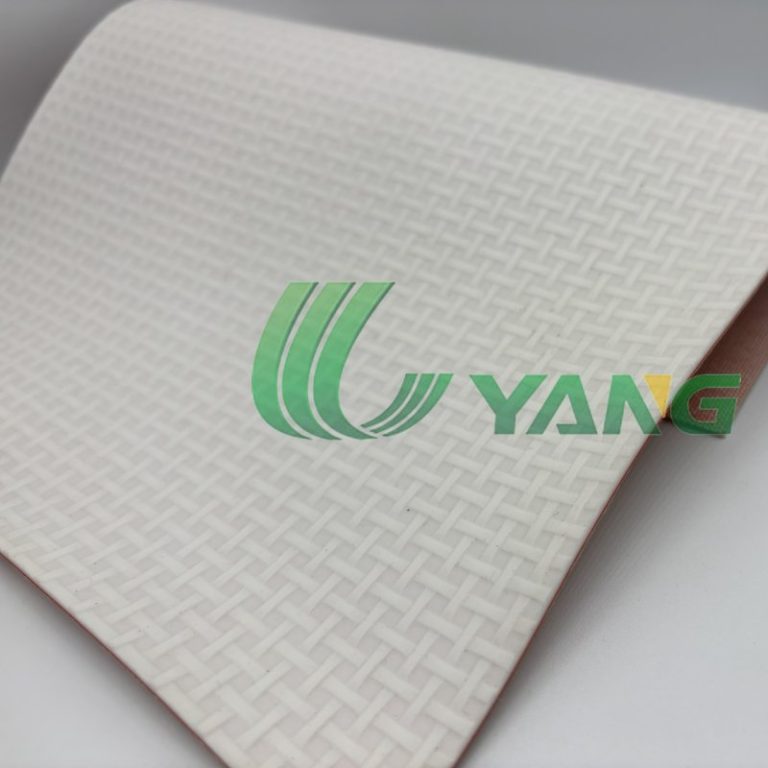

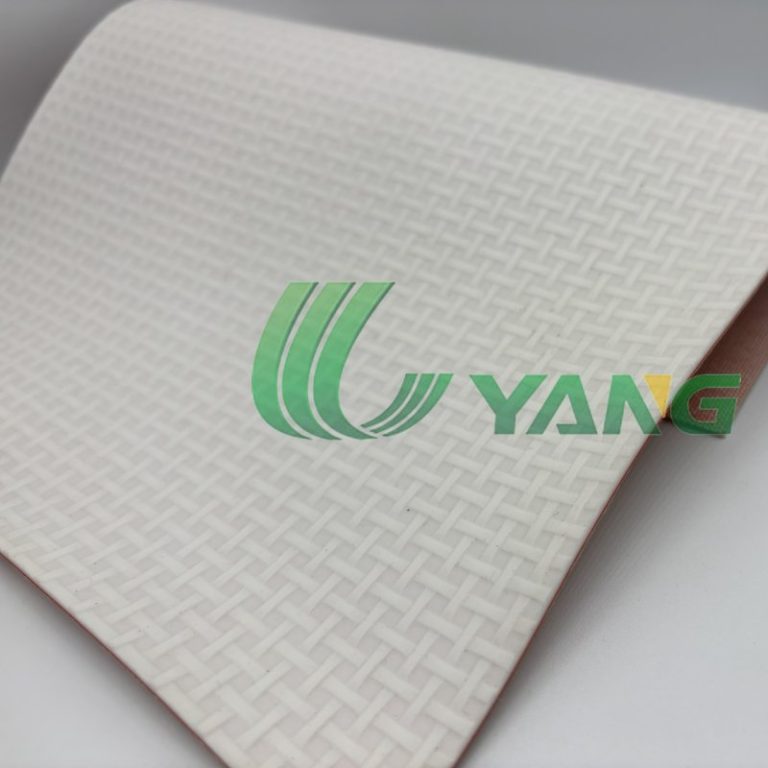

Precision Texture Replication

Soft yet heat-resistant silicone (150°C–200°C) conforms perfectly to the belt’s grooves, maintaining the cross-lattice pattern after splicing.

Non-stick surface prevents adhesive buildup.

High Pressure Resistance

Reinforced with fiberglass/metal inserts to withstand vulcanizer pressure (typically 0.8–1.2 MPa) without deforming the pattern.

Fast & Efficient Curing

Compatible with PU/PVC adhesives and both hot vulcanization and cold bonding processes.

Durable & Reusable

Reusable 200–500 cycles (depending on conditions), reducing long-term costs.

Belt Preparation

Step-lap the belt ends, clean, and apply splicing cement (e.g., RMA adhesive).

Mold Alignment

Align the silicone mold with the cross-pattern and clamp in place.

Vulcanization/Curing

Pressurize (0.8–1.2 MPa) and heat (140°C–160°C) for 10–30 minutes.

Cooling & Demolding

Cool gradually, then remove the mold to reveal a seamless, pattern-matched joint.

| Feature | Silicone Mold | Metal/Rigid Mold |

|---|---|---|

| Pattern Integrity | Preserves intricate textures | May flatten grooves |

| Versatility | Fits complex patterns (cross, herringbone) | Limited to flat/simple belts |

| Efficiency | Easy demolding, less downtime | Prone to adhesive sticking |

Mining, food processing, logistics (patterned PVC/PU belts).

Anti-slip conveyors requiring texture continuity at joints.

Reliable delivery schedules and warehousing support.

Competitive pricing to maximize overall value.

Diverse options to cater to all market segments.

Flexible MOQ Support with all types of goods;

Personalized logo customization on the products

Provide online technical support for all product usage and installation processes

Quick first response to all inquiry and questions

Provide quality images, Video to enhance sales revenue

Efficient production and ship within 15 days at the fastest.

Generally it is 10-15 days, if peak season, it will be about 15-20 day safter receiving the deposit

1. Confirmed Specification: thickness,color, plies,characteristic, and industry;

2. Samples sending: we send samples for you check.or you send us samples if customized belt.

3. Confirm Order: Signing sales contract after samples confirmed.

4. Deposit: 30% deposit before mass production.

5. Production arranged : we will process the production.

6. Remaining payment: after inspection, balance before shipment.

7. Shipping: we will ship the goods to destination port.

8. Confirm bill of loading/commercial invoice/packing list/certificate of origin;