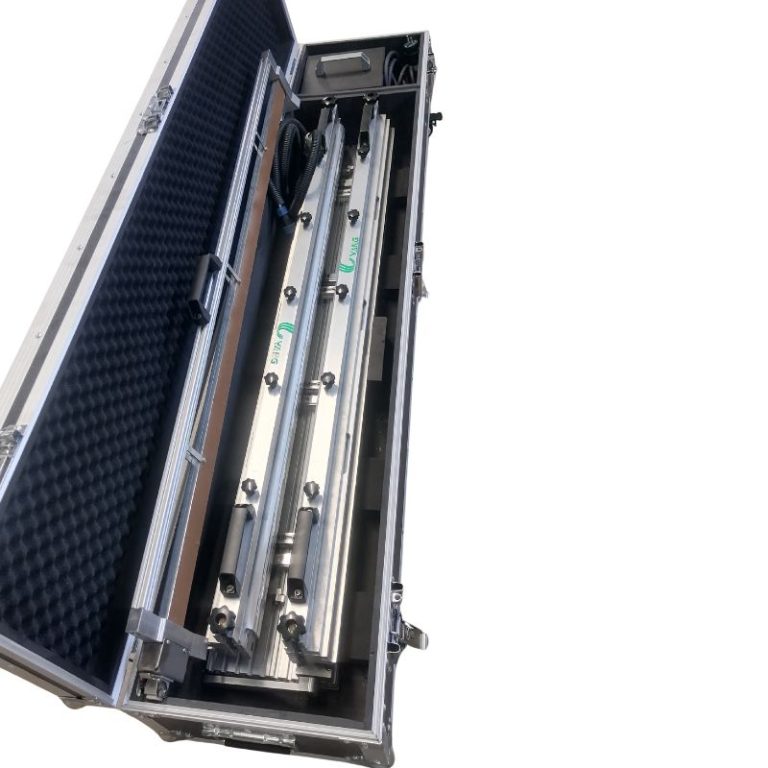

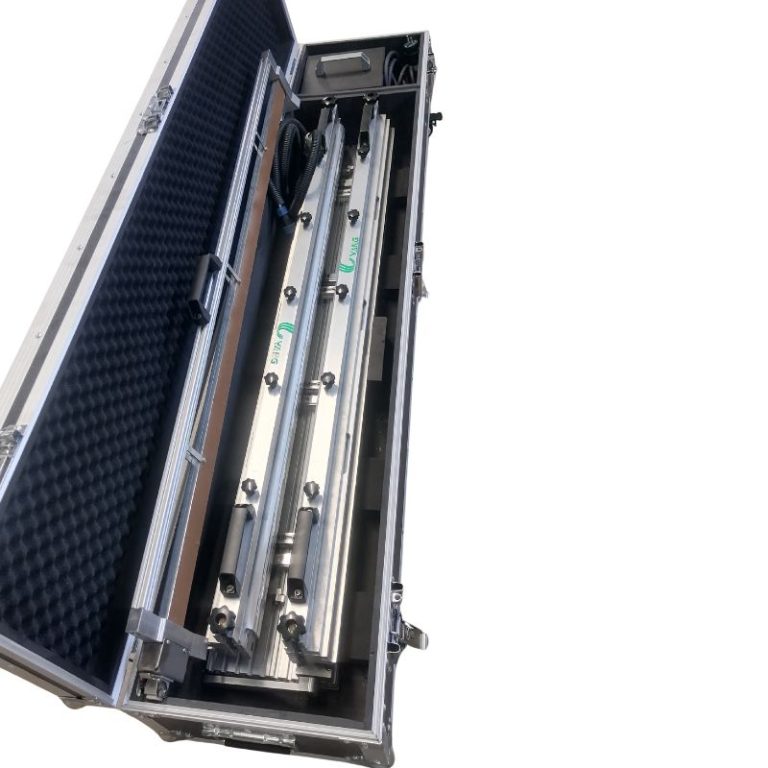

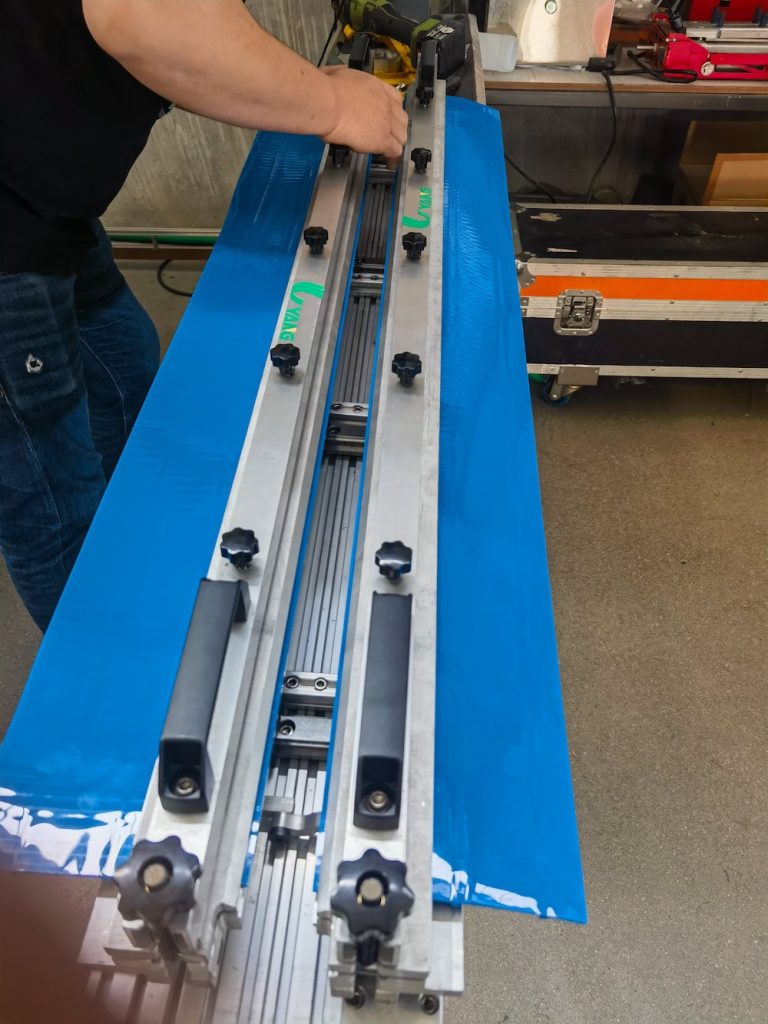

UYANG BELTING a specialized joining machine for easy-to-clean conveyor belts, featuring rapid thermal fusion to create seamless, hygienic joints in minutes. Customizable for belt widths (150-2000mm) and profiles, it ensures strong, FDA-compliant splices without adhesives. Ideal for food and pharmaceutical applications requiring fast, contamination-free belt repairs. and the length of machine could be customized; fast delivery , and with the flight case as package, easy to move during work;

UYANG BELTING a specialized joining machine for easy-to-clean conveyor belts, featuring rapid thermal fusion to create seamless, hygienic joints in minutes. Customizable for belt widths (150-2000mm) and profiles, it ensures strong, FDA-compliant splices without adhesives. Ideal for food and pharmaceutical applications requiring fast, contamination-free belt repairs. and the length of machine could be customized; fast delivery , and with the flight case as package, easy to move during work;

1. Precision Splicing Technology

2. Modular Design

3. Industrial Durability

4. Smart Temperature Management

5. Premium Accessories

![]()

To repair and restore production promptly when the conveyor belt breaks due to mechanical failure in the production process, UYANG BELTING introduces a quick splicing machine, which is simple and convenient to operate, enabling on-site installation and repair of the conveyor belt. The specific operation and equipment specifications are available online by contacting the corresponding salesperson.

Our complete splicing solution includes everything needed for perfect belt joining:

| Metric | Conventional | UYANG BELTING |

|---|---|---|

| Splicing Time | 8-10 min | ≤3 min |

| Temp Variation | ±15°C | ±1°C |

| Joint Strength | 70-80% | 85-95% |

Key Features:

✔ High-Speed Operation – Complete splices 60% faster than conventional methods

✔ Custom Sizing – Adjustable for belt widths from 150mm to 2000mm

✔ Hygienic Design – Stainless steel contact surfaces with IP54 protection

✔ Precision Control – Digital temperature regulation (±1°C) for consistent bond strength

Technical Advantages:

Custom Solutions Available:

• Special jigs for unique belt profiles

• Mobile units for in-line maintenance

• Training packages for operator certification

Reliable delivery schedules and warehousing support.

Competitive pricing to maximize overall value.

Diverse options to cater to all market segments.

Flexible MOQ Support with all types of goods;

Personalized logo customization on the products

Provide online technical support for all product usage and installation processes

Quick first response to all inquiry and questions

Provide quality images, Video to enhance sales revenue

Efficient production and ship within 15 days at the fastest.

Generally it is 10-15 days, if peak season, it will be about 15-20 day safter receiving the deposit

1. Confirmed Specification: thickness,color, plies,characteristic, and industry;

2. Samples sending: we send samples for you check.or you send us samples if customized belt.

3. Confirm Order: Signing sales contract after samples confirmed.

4. Deposit: 30% deposit before mass production.

5. Production arranged : we will process the production.

6. Remaining payment: after inspection, balance before shipment.

7. Shipping: we will ship the goods to destination port.

8. Confirm bill of loading/commercial invoice/packing list/certificate of origin;