UYANG BELTING high-performance conveyor belts are built for demanding gypsum board manufacturing. With heat resistance up to 120°C and anti-stick surfaces, they ensure smooth, uninterrupted production. Custom sizes and patterns available to perfectly match your production line. Trusted by manufacturers worldwide for reliable, cost-effective solutions.

UYANG BELTING high-performance conveyor belts are built for demanding gypsum board manufacturing. With heat resistance up to 120°C and anti-stick surfaces, they ensure smooth, uninterrupted production. Custom sizes and patterns available to perfectly match your production line. Trusted by manufacturers worldwide for reliable, cost-effective solutions.

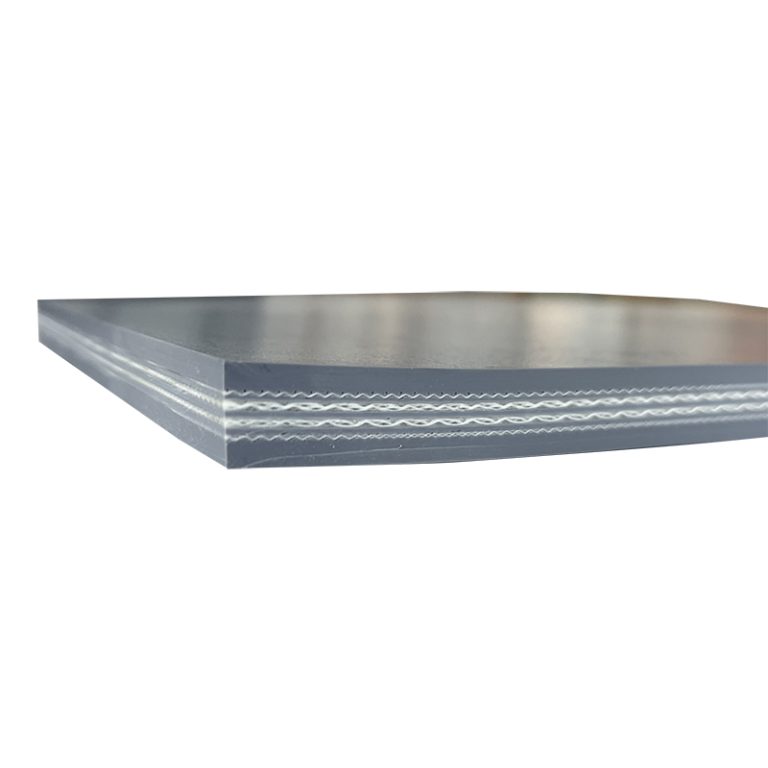

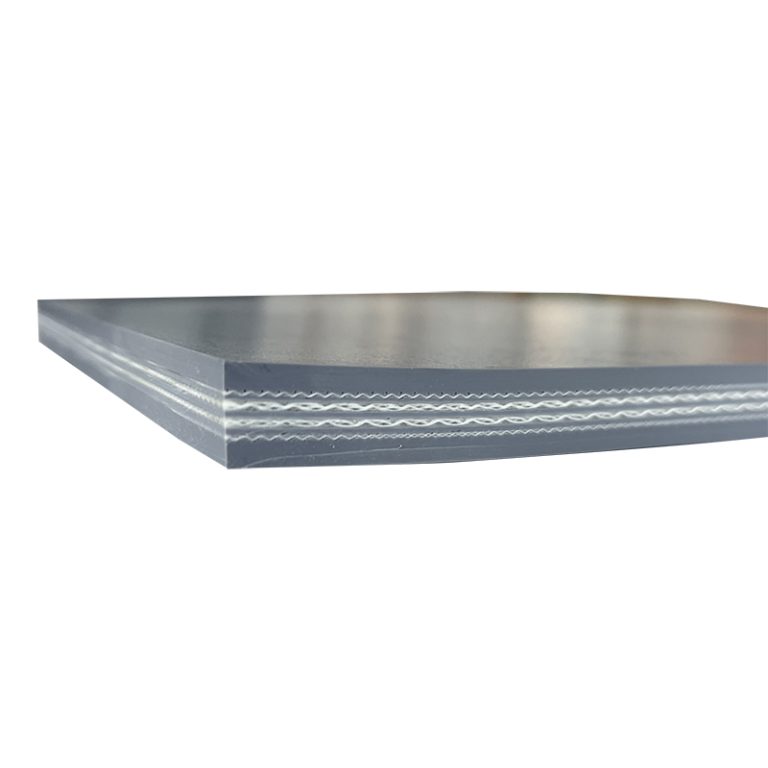

Gypsum Board Conveyor Belts:

Heat-Resistant & Durable – Withstands high temperatures (up to 120°C/248°F) and heavy loads for long-lasting performance.

Anti-Stick Surface – Prevents gypsum buildup, reducing downtime and maintenance costs.

Customizable Fit – Tailored widths, thicknesses, and patterns to match your production line perfectly.

Ideal for seamless gypsum board manufacturing!

Uyang Belting specializes in heavy-duty conveyor belts designed specifically for the gypsum board industry. Our belts ensure smooth, efficient, and trouble-free production while reducing operational costs.

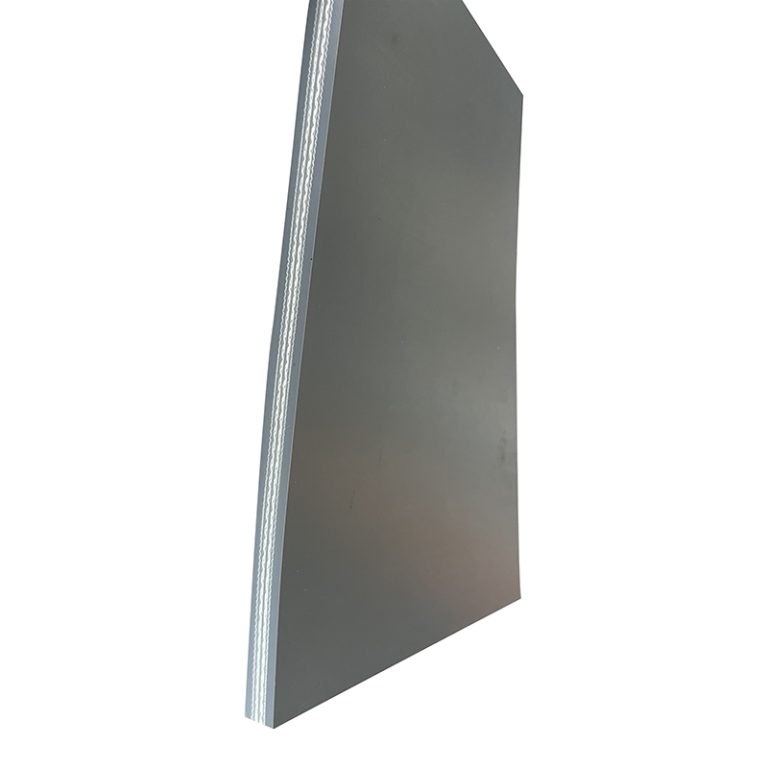

| TECHNICAL CHARACTERISTICS : | |

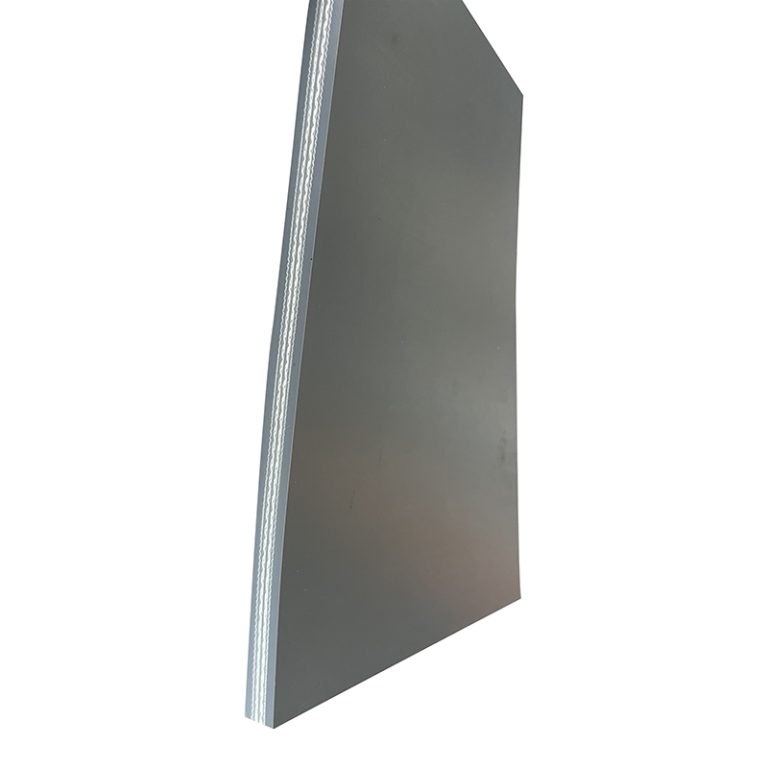

| Total Thickness | 14.5 mm |

| No. of Plies | 4 |

| Fabric | Polyester |

| Weft | Light rigid |

| Weight | 18.0kg(s)/㎡ |

| Working Temperatures | -15 ºC to + 80 ºC |

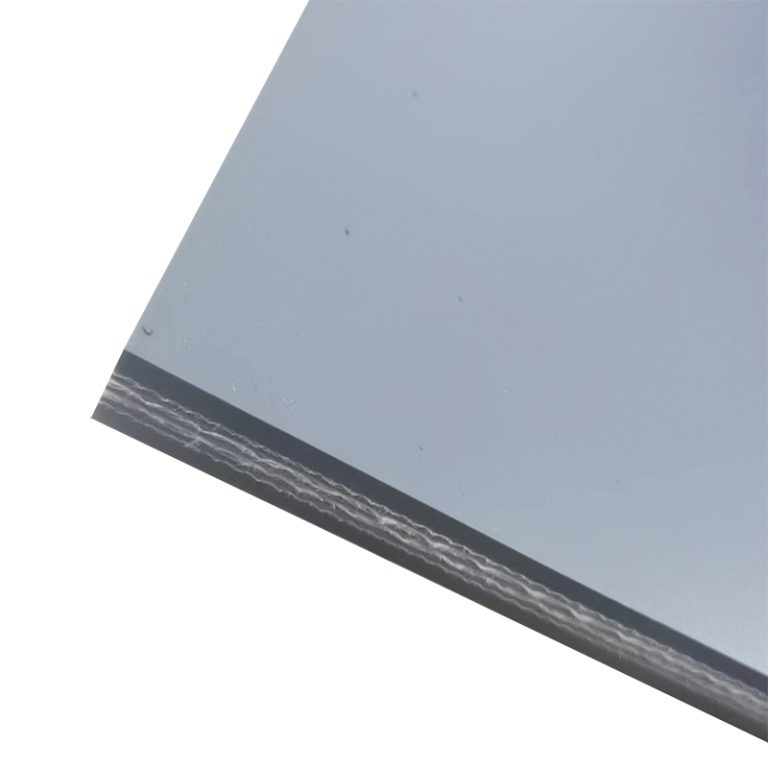

| 1. Top cover | |

| Thickness | 4.0 mm |

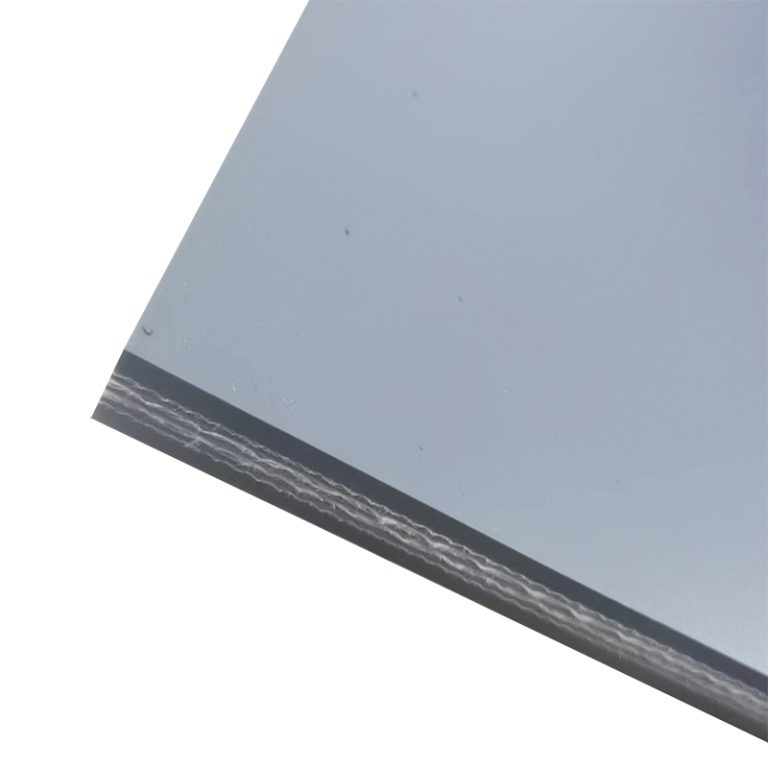

| Material | PVC |

| Color | Gray |

| Surface | Matt |

| Hardness | 75-80 ShA |

| 2. Internal layer(s) | |

| Material | PVC |

| Color | Gray |

| Fabric | |

| 3. Bottom cover | |

| Thickness | 4.0 mm |

| Material | PVC |

| Color | Gray |

| Surface | Matt |

| Hardness | 75-80 ShA |

| Anti-static Yarn | No |

| BELT TENSION: | |

| Tensile Strength(N/mm) | 900 |

| Max. Suggested Load(N/mm) | 72 |

| Working load 1% elongation(N/mm) | 75 |

| FRICTION COEFFICIENTS ON: | |

| Smooth Stainless Steel | 0.35 |

| REMARKS | |

| Max. manufacturing width | 1400mm |

✔ Superior Durability – Reinforced with high-tensile materials to handle heavy loads and continuous operation.

✔ Heat & Moisture Resistant – Withstands high temperatures and humidity in drying processes.

✔ Anti-Stick Surface – Prevents gypsum buildup, minimizing downtime for cleaning.

✔ Precision Edge Guidance – Ensures straight tracking, reducing material waste.

✔ Low Maintenance – Long-lasting construction reduces replacement frequency.

✔ Customizable Solutions – Available in various widths, thicknesses, and surface patterns to fit your production line.

Gypsum board drying lines

Panel cutting & stacking systems

Packaging & handling conveyors

Reliable delivery schedules and warehousing support.

Competitive pricing to maximize overall value.

Diverse options to cater to all market segments.

Flexible MOQ Support with all types of goods;

Personalized logo customization on the products

Provide online technical support for all product usage and installation processes

Quick first response to all inquiry and questions

Provide quality images, Video to enhance sales revenue

Efficient production and ship within 15 days at the fastest.

Generally it is 10-15 days, if peak season, it will be about 15-20 day safter receiving the deposit

1. Confirmed Specification: thickness,color, plies,characteristic, and industry;

2. Samples sending: we send samples for you check.or you send us samples if customized belt.

3. Confirm Order: Signing sales contract after samples confirmed.

4. Deposit: 30% deposit before mass production.

5. Production arranged : we will process the production.

6. Remaining payment: after inspection, balance before shipment.

7. Shipping: we will ship the goods to destination port.

8. Confirm bill of loading/commercial invoice/packing list/certificate of origin;