UYANG BELTING Green Nitrile Rubber Belt is used for shoemaking machinery, shoe forming, gluing, pressing, and finishing processes.with optimal flexibility, durability, and oil resistance. The material is high-grade NBR (nitrile rubber), with excellent resistance to oils, adhesives, and chemicals.

UYANG BELTING Green Nitrile Rubber Belt is used for shoemaking machinery, shoe forming, gluing, pressing, and finishing processes.with optimal flexibility, durability, and oil resistance. The material is high-grade NBR (nitrile rubber), with excellent resistance to oils, adhesives, and chemicals.

Shoe Manufacturing Equipment

(Lasting machines, gluing machines, conveyor sections for assembly and pressing)

Footwear Production Lines

(Sports shoes, leather shoes, casual shoes, industrial footwear)

Light Industrial Processing

Where oil or chemical resistance is essential

| Item | Details |

|---|---|

| Material | NBR (Nitrile Rubber) |

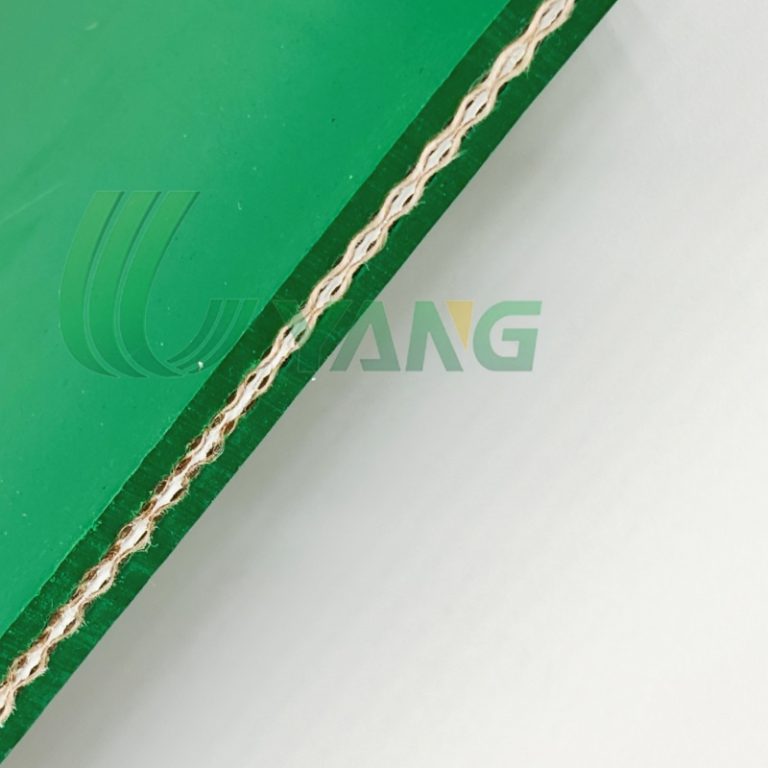

| Color | Green |

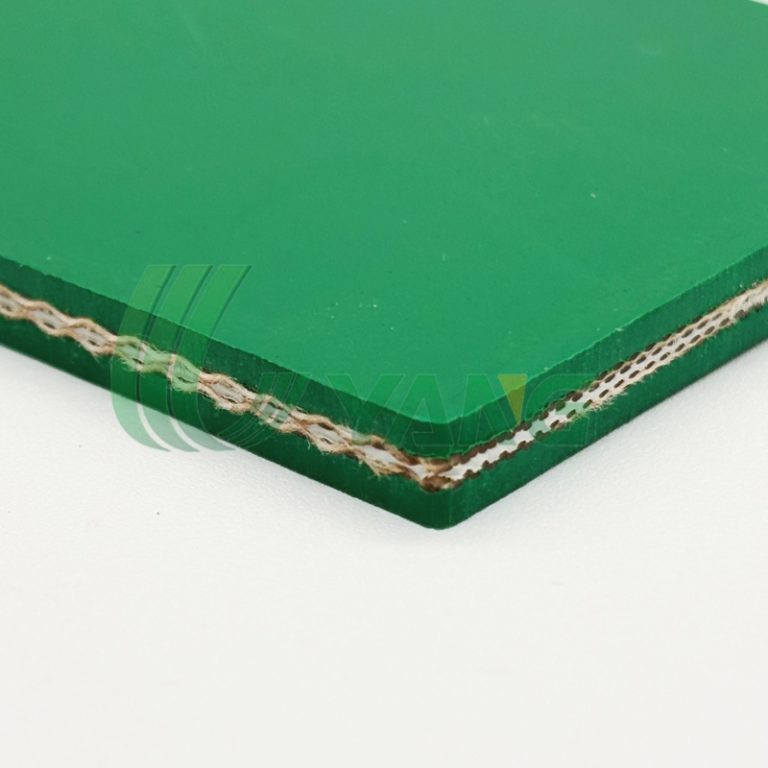

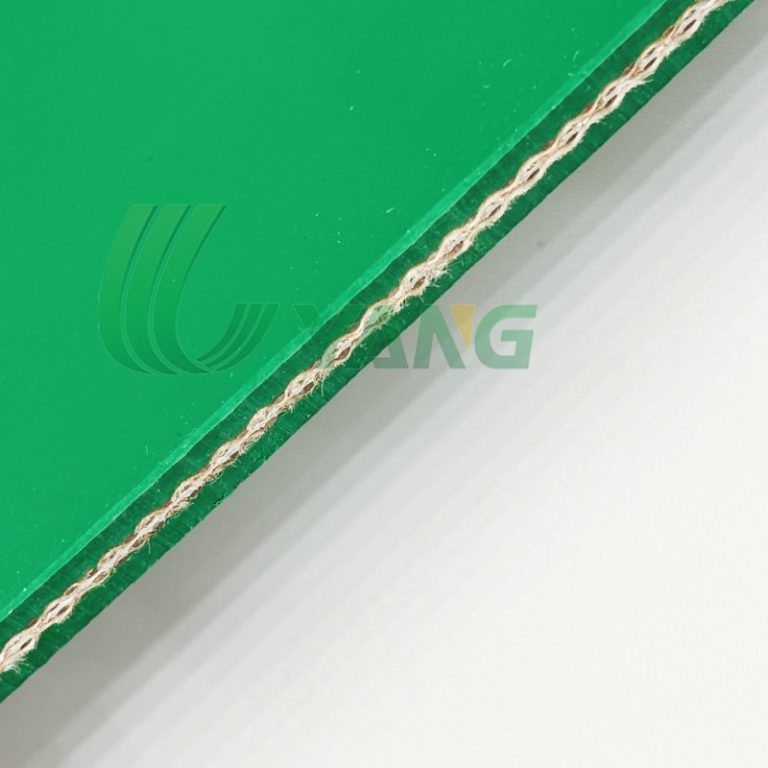

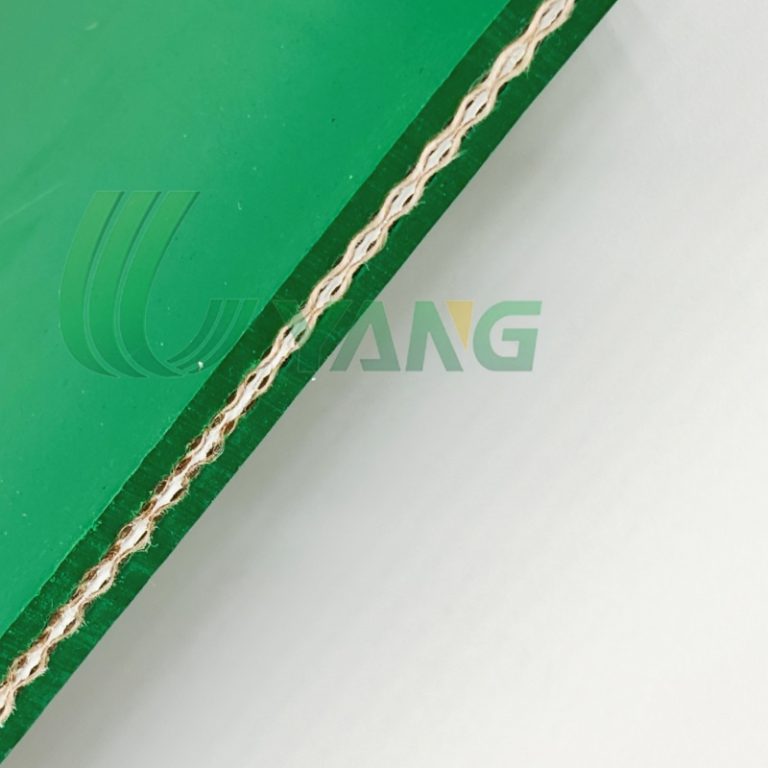

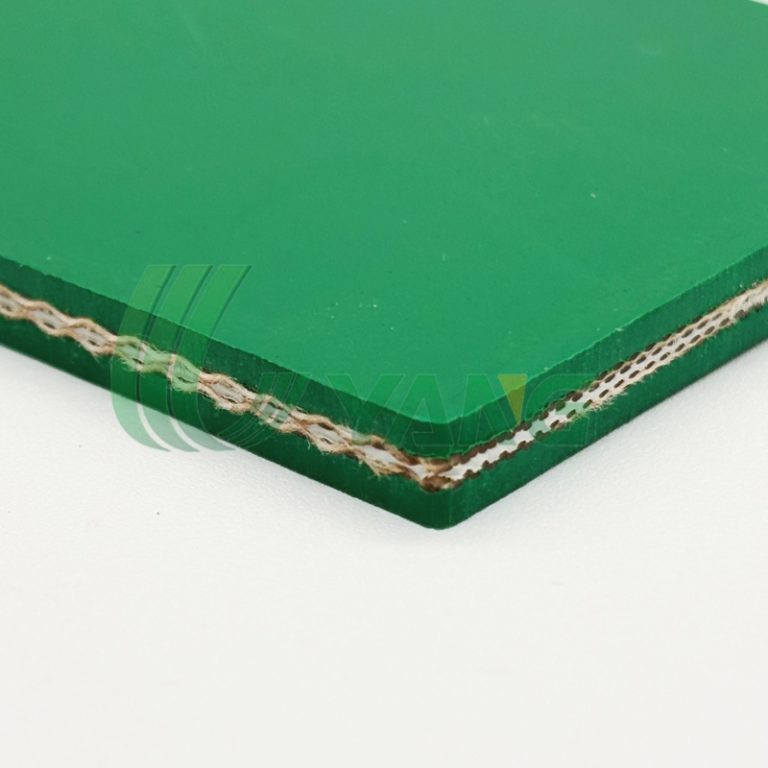

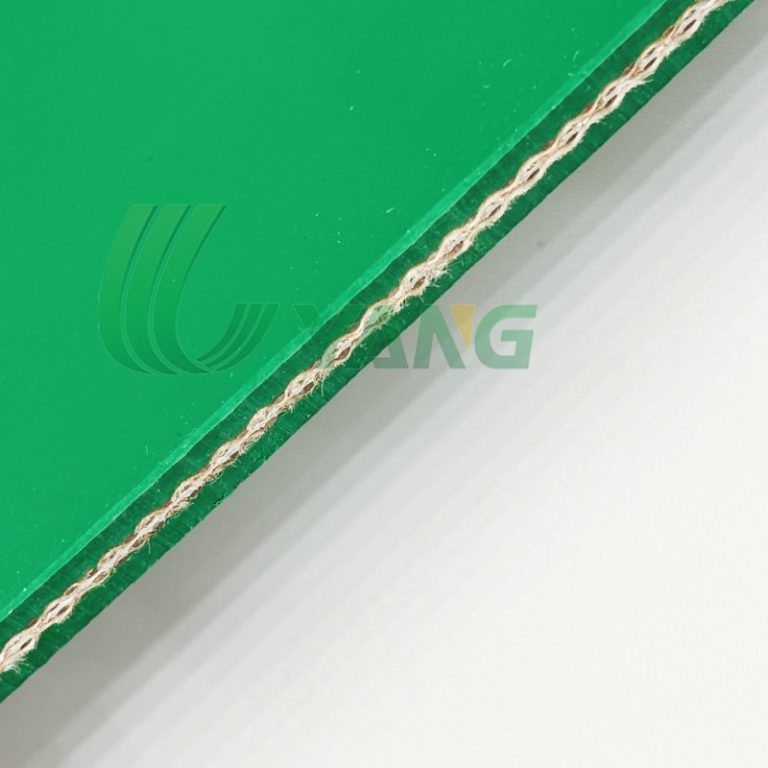

| Structure | 2 Ply Fabric / 3 Rubber Layers |

| Total Thickness | 5.0 mm |

| Key Features | Oil-resistant, glue-resistant, flexible |

| Application Focus | Shoe production equipment, light industry |

✅ Optimized for Shoemaking Machines

Tailored for the demands of continuous operation, frequent stop/start, and tight roller radii.

✅ NBR Material – Oil & Adhesive Resistant

Excellent resistance to glue, oil mist, and solvents, minimizing belt degradation in production areas.

✅ Flexible Yet Strong Structure (2 Ply / 3 Rubber Layers)

Provides enough tension stability while ensuring smooth tracking over small pulleys.

✅ Long Service Life

Withstands wear from repetitive load and discharge, improving productivity and reducing downtime.

✅ Consistent Surface Grip

Surface texture can be customized (smooth, matte, or light grain) to support stable material handling.

Reliable delivery schedules and warehousing support.

Competitive pricing to maximize overall value.

Diverse options to cater to all market segments.

Flexible MOQ Support with all types of goods;

Personalized logo customization on the products

Provide online technical support for all product usage and installation processes

Quick first response to all inquiry and questions

Provide quality images, Video to enhance sales revenue

Efficient production and ship within 15 days at the fastest.

Generally it is 10-15 days, if peak season, it will be about 15-20 day safter receiving the deposit

1. Confirmed Specification: thickness,color, plies,characteristic, and industry;

2. Samples sending: we send samples for you check.or you send us samples if customized belt.

3. Confirm Order: Signing sales contract after samples confirmed.

4. Deposit: 30% deposit before mass production.

5. Production arranged : we will process the production.

6. Remaining payment: after inspection, balance before shipment.

7. Shipping: we will ship the goods to destination port.

8. Confirm bill of loading/commercial invoice/packing list/certificate of origin;