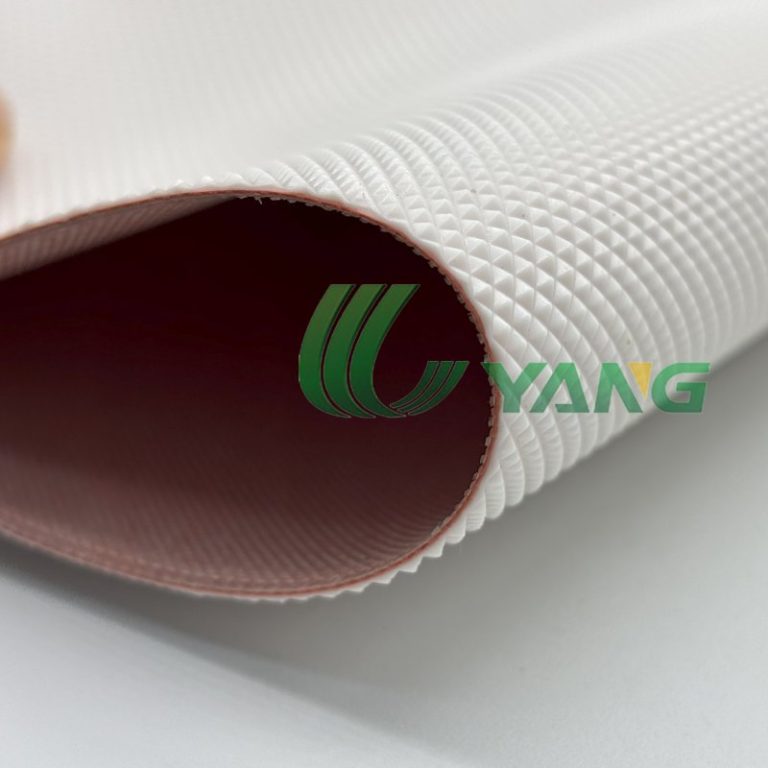

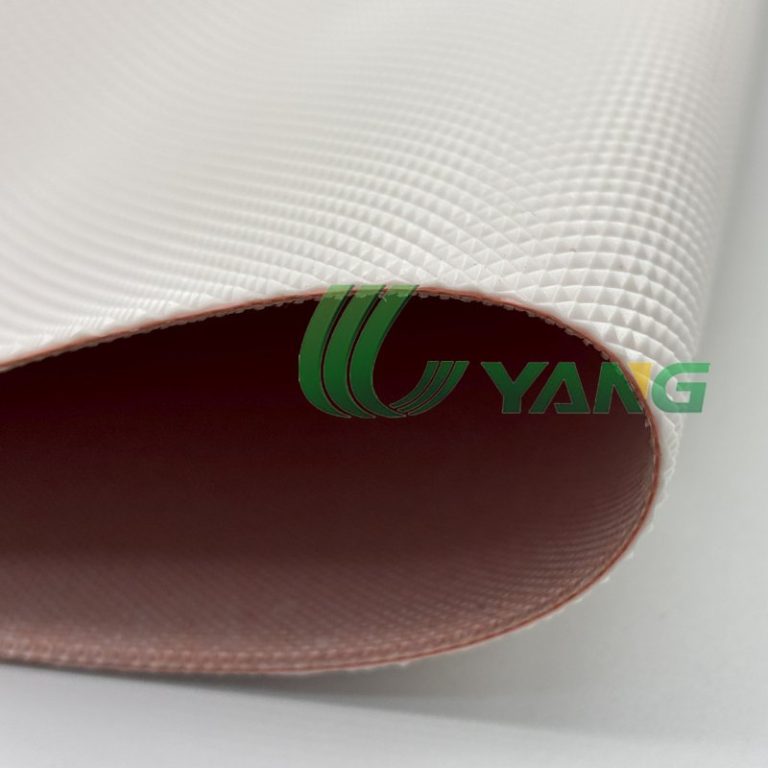

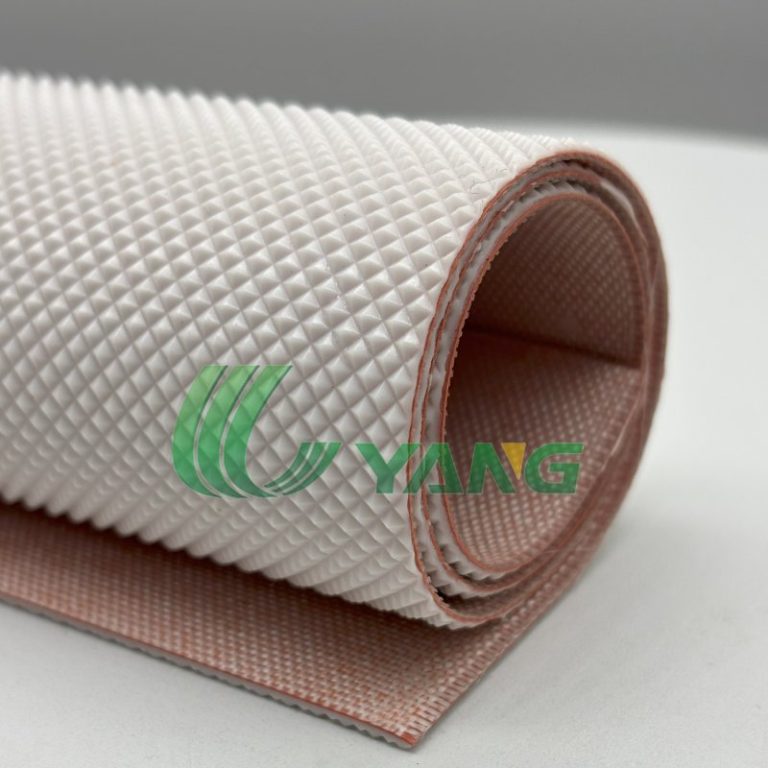

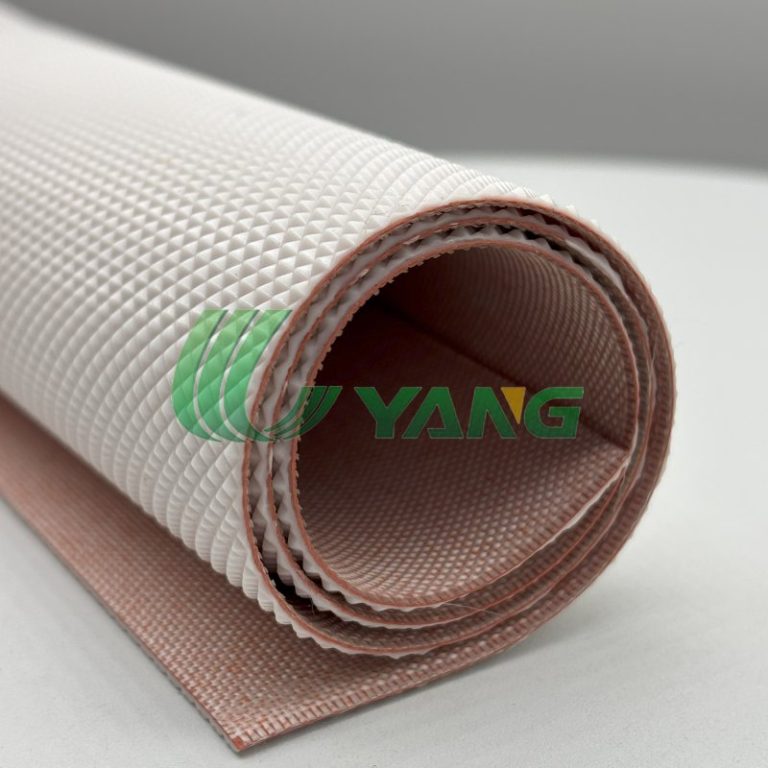

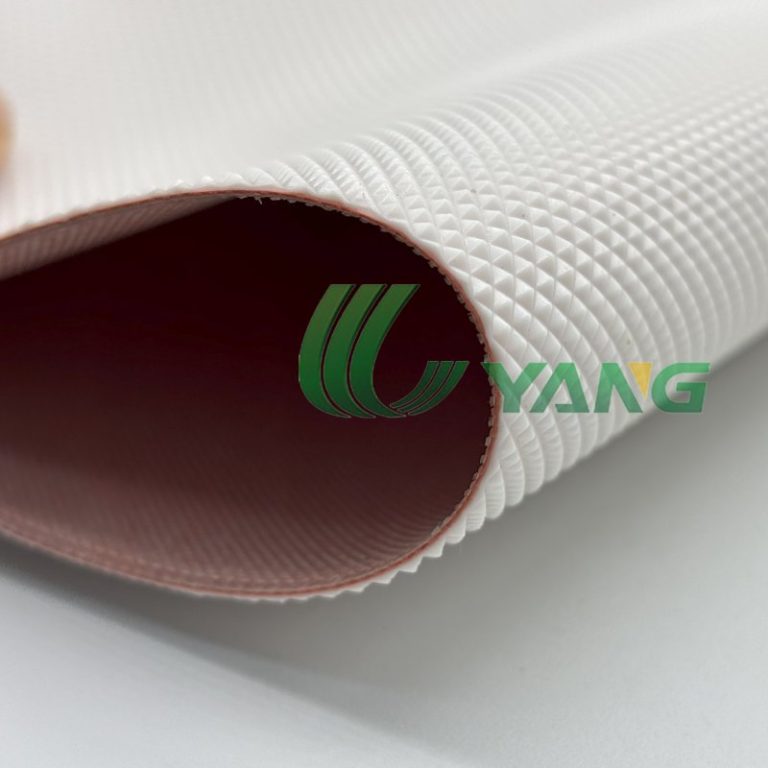

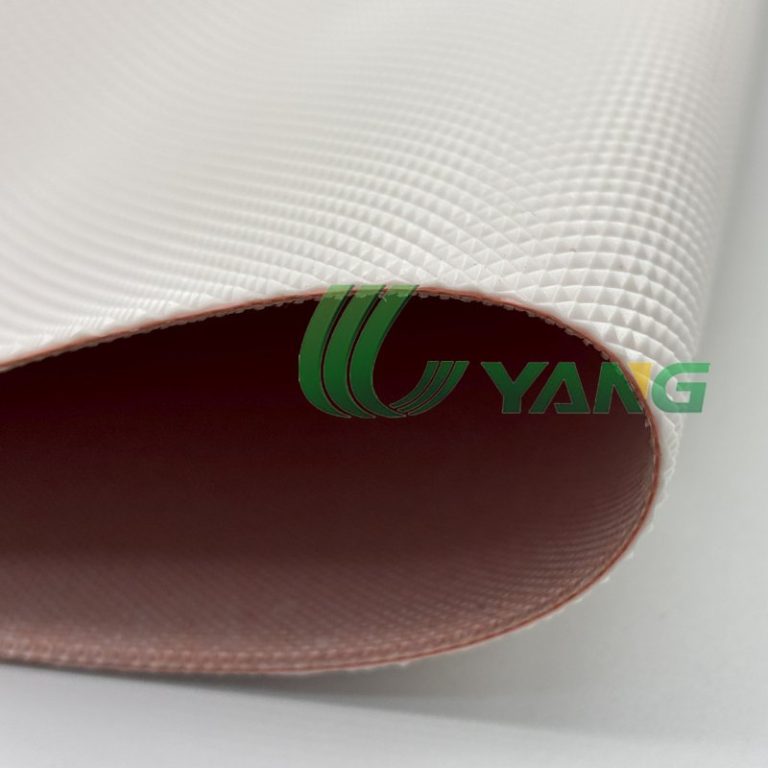

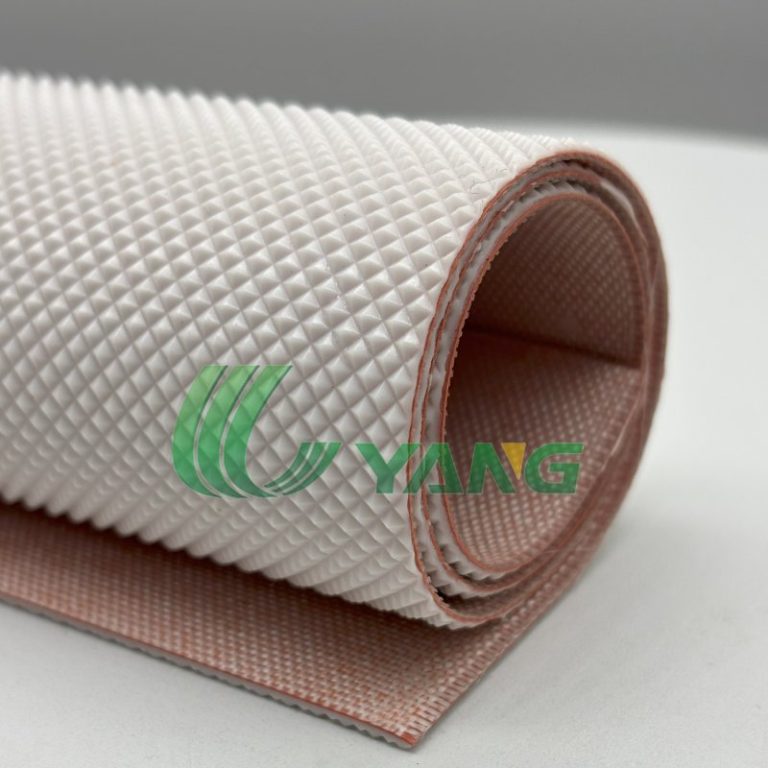

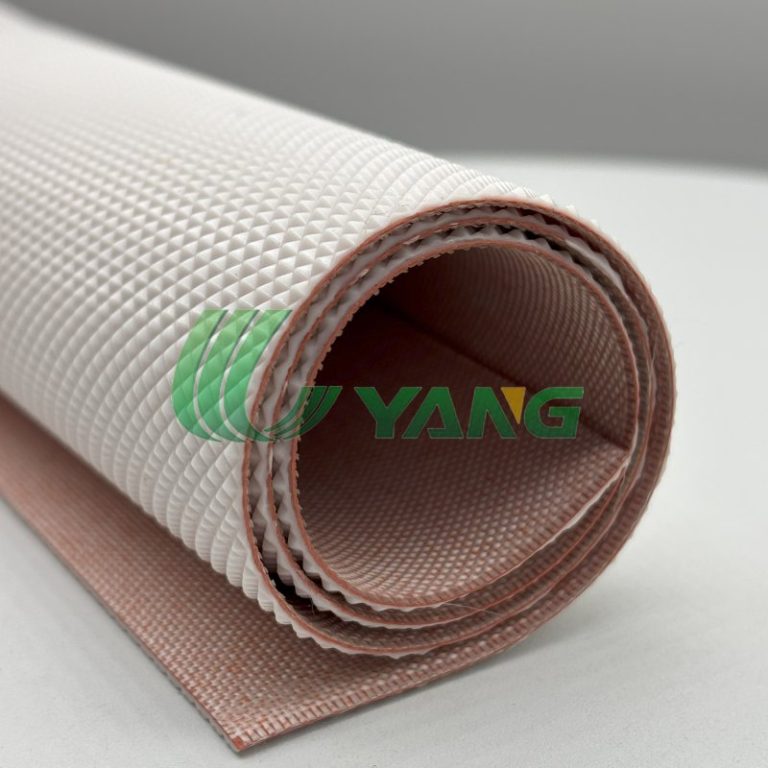

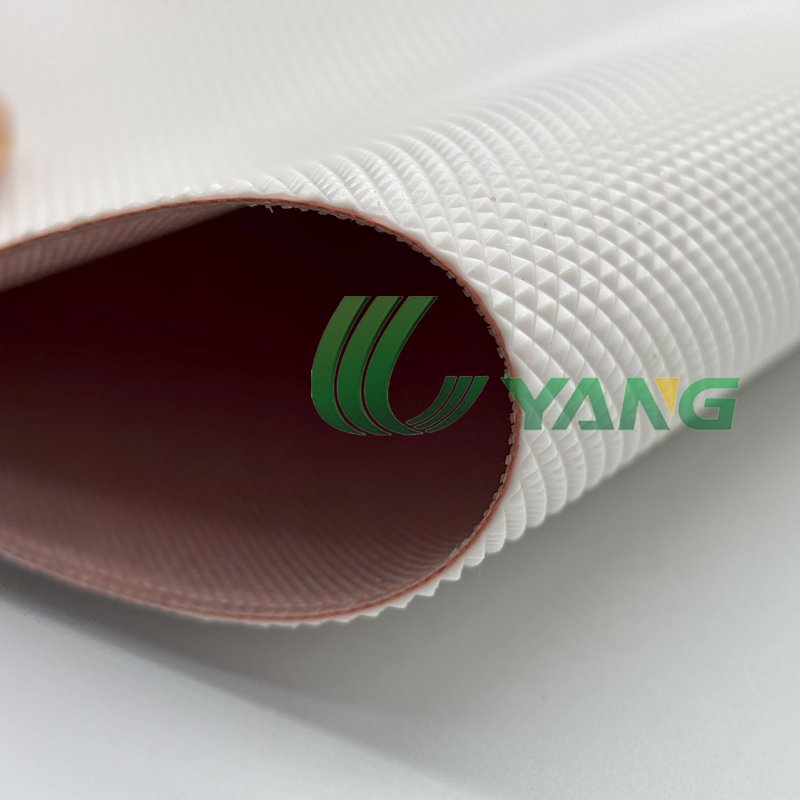

UYANG BELTING diamond-pattern silicone molds are precision-made tools used during hot-press or vulcanizing splices of diamond-top PVC and PU belts. They transfer the original diamond texture into the splice joint, delivering consistent grip, appearance, and performance across the whole belt.

UYANG BELTING diamond-pattern silicone molds are precision-made tools used during hot-press or vulcanizing splices of diamond-top PVC and PU belts. They transfer the original diamond texture into the splice joint, delivering consistent grip, appearance, and performance across the whole belt.

Key Advantages:

Preserves Diamond Texture – keeps the original anti-slip pattern intact at the splice.

Durable & Heat-Resistant – high-quality silicone withstands repeated hot-press use.

Professional Finish – ensures smooth, uniform joints for better grip and appearance.

Diamond Silicone Mold- For Jointing Diamond PVC PU Belt-UYANG BELTING

Key benefits

Texture continuity — reproduces the diamond pattern at the splice so there’s no change in grip or product handling.

Professional finish — creates smooth, low-profile joints that match the rest of the belt visually and functionally.

Durable & heat-resistant — made from high-quality silicone that withstands typical splicing temperatures and repeated use.

Typical specifications & options

Material: high-temperature silicone (food-grade options on request)

Pattern: standard diamond pitch and depth (custom patterns available)

Sizes: standard sheets or custom cut to match belt width and splice length

Thickness: engineered to give correct pattern transfer under standard press settings

Compatibility: designed for PVC and PU conveyor belts with diamond (anti-slip) top surfaces

How it’s used (quick steps)

Prepare and clean belt ends; trim to even edges.

Place splice film (if used) and align belt ends in the hot-press.

Position the diamond silicone mold over the splice area with the patterned side facing the belt surface.

Apply heat and pressure per the belt manufacturer’s splicing parameters (temperature/time/pressure).

Allow the joint to cool; remove the mold and inspect the pattern transfer.

Trim and finish edges as needed, then test under load.

Applications

Splicing diamond-top PVC/PU belts for food, packaging, logistics and light industry lines.

On-site repairs and factory splices where consistent grip and visual uniformity are required.

Color/zone matched lines where appearance and hygiene are critical.

Why choose our silicone molds

Precision pattern transfer, robust heat resistance, and custom sizing make our molds the professional choice for maintaining belt performance and a uniform look across splices. They save rework, reduce product slippage at joints, and help maintain cleanable, hygienic surfaces.

Reliable delivery schedules and warehousing support.

Competitive pricing to maximize overall value.

Diverse options to cater to all market segments.

Flexible MOQ Support with all types of goods;

Personalized logo customization on the products

Provide online technical support for all product usage and installation processes

Quick first response to all inquiry and questions

Provide quality images, Video to enhance sales revenue

Efficient production and ship within 15 days at the fastest.

Generally it is 10-15 days, if peak season, it will be about 15-20 day safter receiving the deposit

1. Confirmed Specification: thickness,color, plies,characteristic, and industry;

2. Samples sending: we send samples for you check.or you send us samples if customized belt.

3. Confirm Order: Signing sales contract after samples confirmed.

4. Deposit: 30% deposit before mass production.

5. Production arranged : we will process the production.

6. Remaining payment: after inspection, balance before shipment.

7. Shipping: we will ship the goods to destination port.

8. Confirm bill of loading/commercial invoice/packing list/certificate of origin;