Key Features of Hygienic Conveyor Belts

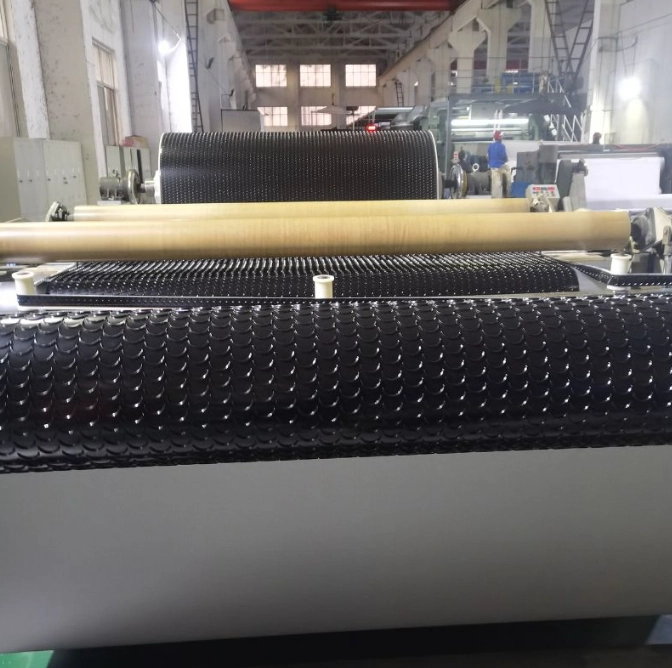

Seamless Construction for Easy Cleaning

How a conveyor belt is built matters a ton for staying clean. Uyang Belting’s homogeneous belts have no seams, fabric, or extra layers. Their smooth design stops dirt and germs from hiding in tiny cracks. This makes cleaning a breeze compared to old-school belts.

Seamless belts are perfect for food processing. They don’t have spots where bacteria can grow. You can wash them quickly and well. They handle hot water, steam, or cleaning chemicals like champs, keeping hygiene super high.

Material Selection and Surface Treatment

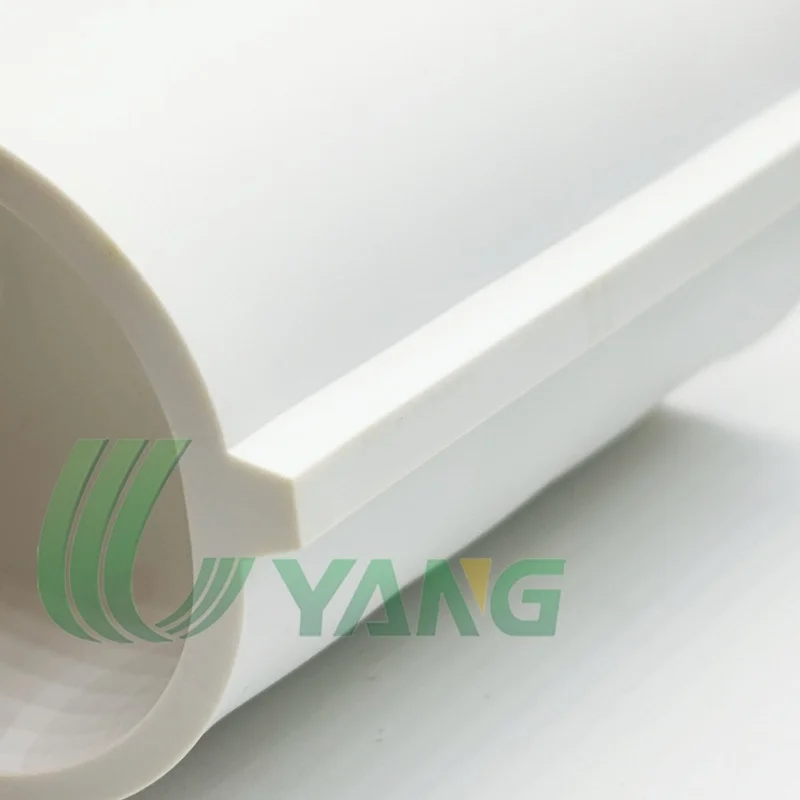

What a belt is made of is key to how good it works. Uyang Belting uses thermoplastic polyurethane (TPU) for its homogeneous belts. TPU fights off oil, water, and germs. Its smooth surface moves food cleanly without soaking up bits or liquids.

Food-grade belts must follow tough rules, like FDA and EU certifications, to keep food safe. Uyang Belting’s TPU belts meet these standards. They’re great for touching food directly in delicate jobs like dairy, meat, and bakery processing.

Design Considerations for Hygiene

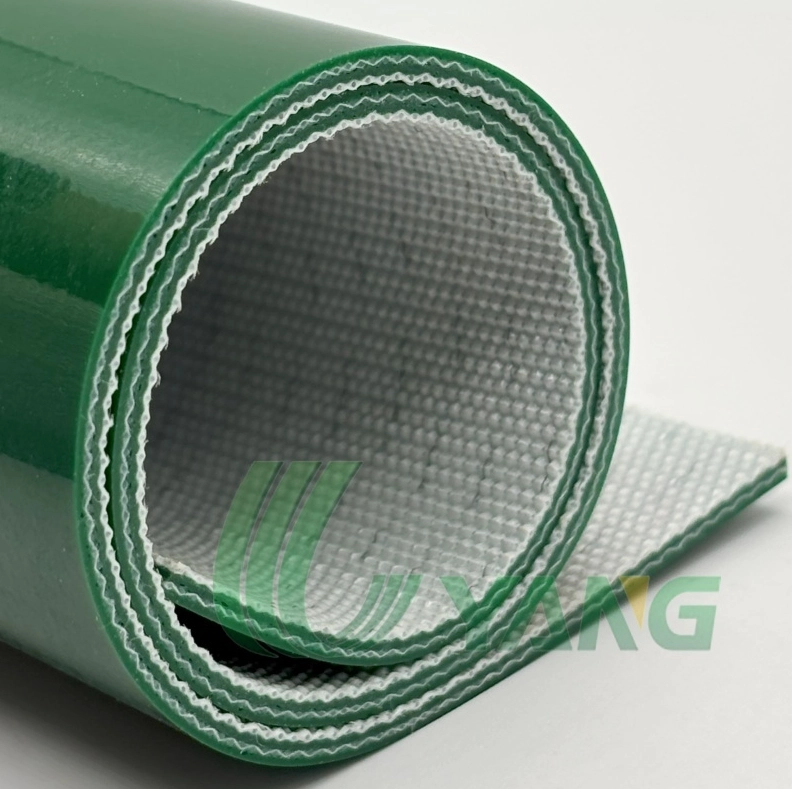

Besides materials, the belt’s surface can change how clean it stays. Uyang Belting’s homogeneous belts can have smooth or lightly textured surfaces, like diamond patterns or small ribs. These textures stop slipping but are still easy to clean. They keep food from sticking around.

In fast-moving food lines, belts can’t trap food bits. A smooth surface cuts this risk. Textured surfaces help grip things like bakery dough. Plus, Uyang Belting’s belts have sealed edges. This stops liquids and food from sneaking inside, which makes hygiene even better.

Industry-Specific Applications

Dairy Processing

In dairy work, being super clean is a must, especially for milk, cheese, and butter. Uyang Belting’s homogeneous belts are a great match. Their seamless, smooth design carries dairy products safely. No food bits, germs, or bacteria can hang out.

Dairy belts need to handle lots of washing and hot temperatures. Uyang Belting’s belts are tough in these conditions. They stay strong and save time on cleaning or fixes.

Meat Processing

Meat processing is tough because germs spread easily. Uyang Belting’s homogeneous belts are awesome for this. They resist cuts, germs, and water damage, making them perfect for raw meat, poultry, and seafood.

Cleaning belts well after each batch stops germs from jumping between meats. This keeps products safe for customers and companies alike.

Bakery Processing

In bakeries, belts move dough, baked goods, and other stuff that needs to stay really clean. Uyang Belting’s TPU-based homogeneous belts are ideal. Their non-sticky surfaces are easy to clean and keep germ-free.

Bakery belts often deal with high heat but must stay clean. These belts hold up great under different conditions. They keep working smoothly through every step of production.

Best Practices for Maintaining Conveyor Belt Hygiene

Cleaning Methods

Washing conveyor belts often is super important to keep them free of germs. Uyang Belting’s homogeneous belts are easy to clean with hot water, steam, or cleaning chemicals. Their smooth surfaces make sure no food bits stick around. This is a big deal for food safety in dairy, meat, and bakery work.

For the best results, make a regular cleaning plan. Automated systems, like Clean-in-Place (CIP), can speed things up. They keep belts clean without slowing down your work.

Maintenance Protocols

Checking belts regularly keeps them clean and working right. Look for wear, damage, or peeling. Uyang Belting’s belts are made strong. They don’t fray or break easily.

Also, check the belt’s tension and alignment a lot. This stops issues like slipping and keeps the belt running nicely.

Employee Training

Teaching workers about keeping things clean is really important. They need to know why hygiene matters, how to clean belts properly, and how to spot problems. Regular training cuts down on mistakes. It helps keep cleanliness high all the time.

Compliance and Standards

Regulatory Requirements

Conveyor belts in food processing have to follow strict rules to keep food safe. Uyang Belting’s products meet global standards like FDA, EU, and HACCP. These certifications show the belts are safe for food production. They won’t cause germ problems.

Knowing and following these rules is a must for dairy, meat, and bakery companies. Using certified belts, like Uyang Belting’s, makes sure products meet local and worldwide safety standards.

Industry Certifications

Uyang Belting’s belts aren’t just for food. They’re also certified for other fields, like medicine and shipping. These certifications prove the belts are safe and work great. They keep production clean and smooth without risks from bad materials or methods.

Additional Tips for Maximum Hygiene

Choosing the Right Belt for Your Needs

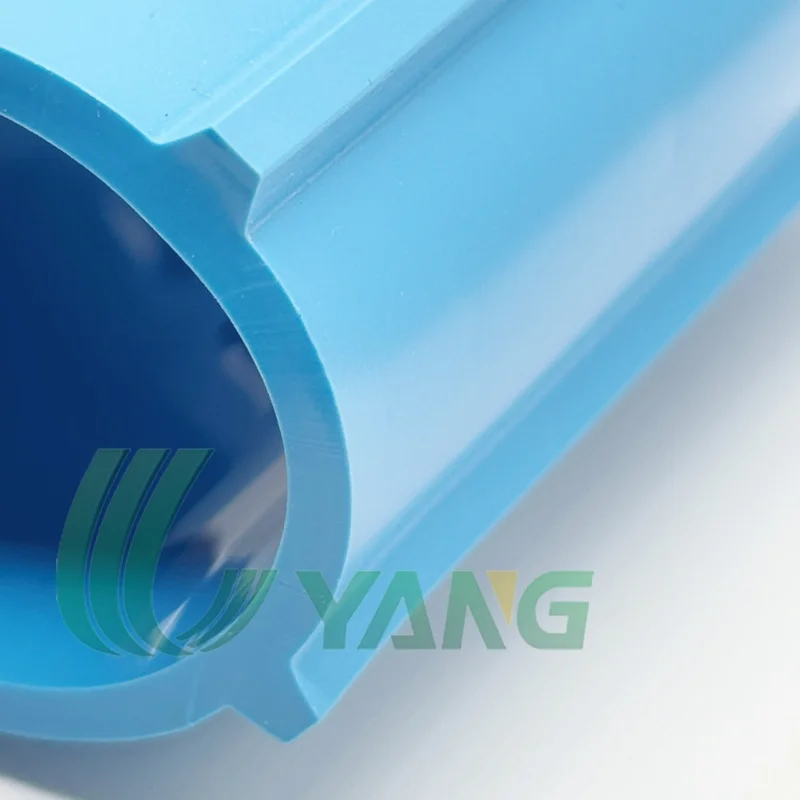

Picking the right belt starts with knowing your production line. Dairy might need belts that handle wet, sticky products like cheese. Meat lines need belts that resist cuts and germs. Bakery lines need belts that grip dough but stay easy to clean. Uyang Belting offers customizable options, like blue belts to spot dirt easily, to fit each job.

Monitoring Cleaning Effectiveness

After cleaning, check if the belt is really clean. Use swabs or tests to make sure no germs are left. This extra step helps catch problems early. It keeps your food line safe and your products high-quality.

Upgrading Old Systems

If your belts are old, they might not meet today’s hygiene rules. Upgrading to Uyang Belting’s homogeneous belts can make a big difference. They’re built for modern food safety needs. Plus, they last longer and need less fixing, saving you time and money.

Working with Suppliers

Talk to your belt supplier, like Uyang Belting, to get advice on what works best. They can help you pick the right belt and share tips on cleaning and maintenance. A good supplier is a partner in keeping your line clean and efficient.

Conclusion

Choosing the right conveyor belt is key to keeping dairy, meat, and bakery processing clean. Uyang Belting’s homogeneous belts are fantastic. Their seamless design, strong build, and awesome hygiene features make them perfect for food safety. Stick to good cleaning, maintenance, and training habits. This lowers germ risks and makes work smoother. With Uyang Belting, you get trusty belts that keep your food production safe, clean, and efficient.

FAQs

Q1: What makes homogeneous conveyor belts more hygienic than regular belts?

A: Homogeneous belts are one solid piece with no seams or fabric. This stops germs from hiding in cracks. Their smooth surfaces are super easy to clean, great for food processing.

Q2: Can Uyang Belting’s conveyor belts be customized for specific food processing needs?

A: Yes! Uyang Belting offers customizable belts. You can choose surface textures, colors (like blue to spot dirt), and sizes to fit dairy, meat, and bakery lines.

Q3: How often should I clean my conveyor belts in food processing?

A: Clean belts after every production run. Use steam or chemical cleaners for deep cleaning. Check belts often and do maintenance to keep them in top shape.