Food processing is a tough job. Keeping things clean and safe is super important. The right conveyor belt can make a big difference. Uyang Belting, a top company with over 20 years making belts, offers Sharp Nipple Pattern Thermoplastic Postive Drive Belt. These belts are great for keeping food safe and making work faster. This guide will help you pick the best Sharp Nipple Pattern Thermoplastic Postive Drive Belt for your food processing needs.

What is a Sharp Nipple Pattern Thermoplastic Postive Drive Belt?

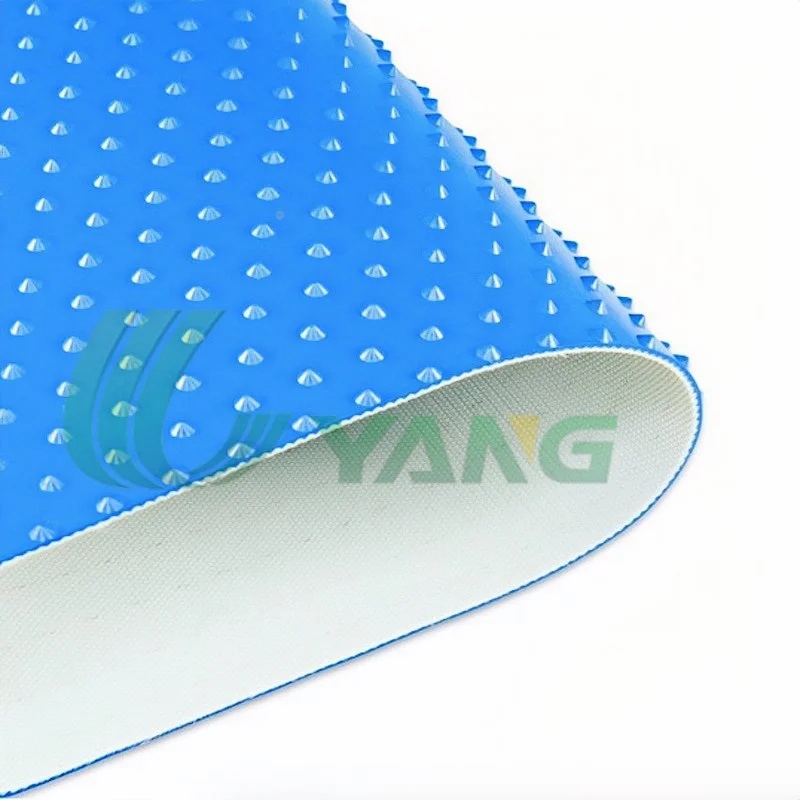

A Sharp Nipple Pattern Thermoplastic Postive Drive Belt is a special conveyor belt. It has a bumpy surface that gives extra grip. Made from one piece of plastic, usually thermoplastic polyurethane (TPU), it has no seams or fabric. This stops germs from hiding in cracks. It’s perfect for jobs like meat, seafood, or dairy processing, where cleanliness is a must. Uyang Belting makes these belts strong and easy to clean.

Key Benefits of Sharp Nipple Pattern Thermoplastic Postive Drive Belts

1. Awesome Hygiene and Food Safety

Keeping food safe is the top goal in food processing. Sharp Nipple Pattern Thermoplastic Postive Drive Belts from Uyang Belting are built for clean work. They have no seams, so germs can’t hide. These belts meet FDA, EU, and USDA rules, so they’re safe for touching food like meat or fish. This is critical as the global food certification market is growing fast. It’s expected to rise from USD 5.22 billion in 2024 to USD 7.95 billion by 2032, with a growth rate of 5.4% per year. This shows how much people care about safe food today (Source: Food Certification Market Size, Share, Trends & Analysis, 2032).

The belts don’t soak up water or oil. This stops germs from growing. They can handle tough cleaning, like hot water, steam, or strong soaps. For example, a quick rinse after cutting fish keeps the belt clean. This helps food plants follow HACCP and GMP rules, keeping food safe for everyone.

2. Tough and Long-Lasting

Sharp Nipple Pattern Thermoplastic Postive Drive Belts are super strong. Uyang Belting designs them to handle hard jobs. They work in hot, wet, or rough places without breaking. The bumpy nipple pattern gives great grip for slippery stuff, like fish or dough. For instance, a meat plant can move wet chicken without slipping.

These belts don’t get cut or damaged easily. They resist germs and tough conditions, so they last a long time. Even if they cost more at first, they save money because you don’t need to replace them often.

3. Easy to Clean and Care For

Cleaning is a big deal in food plants. Downtime hurts work, so fast cleaning matters. Uyang Belting’s Sharp Nipple Pattern Thermoplastic Postive Drive Belts are made for quick cleaning. Their smooth, seamless design has no spots for dirt to stick. Workers can rinse them fast with hot water or steam. They also handle chemical soaps without breaking.

For example, after a shift processing shrimp, a quick wash gets the belt ready for the next job. This cuts cleaning time and keeps the plant running smoothly. No germs get trapped, so food stays safe.

4. Works for Many Food Jobs

Sharp Nipple Pattern Thermoplastic Postive Drive Belts are super flexible. Uyang Belting makes them for all kinds of food work. You can pick the thickness, texture, or color to fit your needs. For example, blue belts help spot dirt easily, which is great for safety.

In meat processing, these belts are awesome for cutting, sorting, or weighing. The nipple pattern keeps meat in place, so nothing slips. In seafood plants, they handle delicate stuff like fish fillets or shrimp. The belts don’t get hurt by water or oils, so they’re perfect for wet jobs. In dairy, they keep cheese or butter safe and clean. These belts work for lots of food tasks.

How to Choose the Right Sharp Nipple Pattern Thermoplastic Postive Drive Belt

Picking the best Sharp Nipple Pattern Thermoplastic Postive Drive Belt means thinking about your plant’s needs. Here are the main things to consider:

1. How Often You Clean and Hygiene Rules

If your plant cleans a lot, like in dairy or meat, pick a belt that’s easy to wash. Uyang Belting’s Sharp Nipple Pattern Thermoplastic Postive Drive Belts have a smooth surface for quick cleaning. This saves time and keeps things super clean. For example, a dairy plant can rinse the belt fast after making cheese.

2. Temperature and Wet Conditions

Think about your plant’s temperature and wetness. Uyang Belting’s belts work in hot or cold places. They’re great for frozen food or hot cooking lines. For instance, a belt can handle frozen shrimp or hot baked goods without breaking.

3. Type of Food and Handling

Different foods need different care. Slippery foods, like fish, need the nipple pattern for grip. Uyang Belting lets you choose textures to match your food. For example, a bumpy belt keeps wet fish fillets from sliding off during sorting.

4. Food Safety Rules

Make sure the belt follows safety rules. Uyang Belting’s Sharp Nipple Pattern Thermoplastic Postive Drive Belts are FDA, EU, and USDA approved. This means they’re safe for touching food directly, like meat or dairy. They help your plant pass safety checks.

More Tips for Picking the Right Belt

Check Your Machines

Make sure the belt fits your machines. Uyang Belting can help pick the right size and design. For example, a belt for a small seafood sorter needs to be thin and precise. Check pulley sizes and angles to avoid slipping. A wrong fit can cause problems, like belts moving off track.

Look for Extra Features

Some belts have cool extras, like metal-detectable parts. These help spot tiny bits if they break off, keeping food safe. Uyang Belting offers these for extra safety. For example, a metal-detectable belt in a meat plant helps find any pieces fast.

Think About Colors

Blue belts are popular in food plants. They make it easy to see dirt or food bits. Uyang Belting offers blue Sharp Nipple Pattern Thermoplastic Postive Drive Belts for this reason. For instance, a blue belt helps workers spot a shrimp piece left behind.

Real-World Examples of Sharp Nipple Pattern Belts

Meat Processing Plant

A meat plant used Uyang Belting’s Sharp Nipple Pattern Thermoplastic Postive Drive Belts for cutting chicken. The nipple pattern kept the meat in place, even when wet. Cleaning was fast, so the plant had less downtime. This helped them process more chicken and save money.

Seafood Processing Line

A shrimp plant had trouble with germs on old belts. They switched to Uyang Belting’s belts. The seamless design stopped germs from growing. The nipple pattern helped move shrimp without slipping. The plant stayed clean and passed safety checks easily.

Dairy Production

A cheese plant needed a belt for wet, sticky cheese. Uyang Belting’s Sharp Nipple Pattern Thermoplastic Postive Drive Belt worked great. It handled the wet environment and cleaned up fast. The belt kept cheese safe and made work smoother.

How to Start Using Sharp Nipple Pattern Belts

Talk to Uyang Belting

Work with Uyang Belting’s experts. They know food processing and can pick the right Sharp Nipple Pattern Thermoplastic Postive Drive Belt. They’ll make sure it fits your machines and needs. For example, they can suggest a belt for a fish filleting line.

Test the Belt

Try the belt on one line first. See how it helps with cleaning and moving food. For instance, test it on a meat sorting line to check if it saves time. If it works well, use it on more lines.

Train Your Workers

Teach your team how to clean and check the belt. Show them how to rinse it and look for wear. A trained team keeps belts working longer and saves money. For example, a quick training session shows workers how to spot dirt on a blue belt.

Why These Belts Are the Future

Sharp Nipple Pattern Thermoplastic Postive Drive Belts are changing food processing. They make it easier to stay clean and meet tough safety rules. They save time and money, which helps plants grow. As more people want safe, high-quality food, these belts will be a must-have. Uyang Belting’s belts are a smart choice for any plant wanting to do better.

Conclusion

Picking the right Sharp Nipple Pattern Thermoplastic Postive Drive Belt is key to keeping food safe and work fast. Uyang Belting’s belts offer great hygiene, toughness, and easy cleaning. They’re perfect for meat, seafood, or dairy plants. By thinking about cleaning needs, temperature, food type, and safety rules, you can choose the best belt. With Uyang Belting’s help, your plant will stay clean, save money, and work better for years.

FAQs

Q1: What industries can use Sharp Nipple Pattern Thermoplastic Postive Drive Belts?

A: Sharp Nipple Pattern Thermoplastic Postive Drive Belts are used in meat processing, seafood handling, dairy production, bakery, and pharmaceutical industries, among others.

Q2: Can these belts be used in high-temperature environments?

A: Yes, Uyang Belting’s Sharp Nipple Pattern Thermoplastic Postive Drive Belts are designed to withstand high-temperature environments, making them ideal for applications in cooking, pasteurization, and other high-heat processes.

Q3: Are Sharp Nipple Pattern Thermoplastic Postive Drive Belts FDA approved?

A: Yes, Uyang Belting’s belts are FDA, EU, and USDA certified, ensuring compliance with global food safety standards for direct food contact.