Picking the right conveyor belt for food processing is a big deal. It helps keep things running smoothly, keeps food safe, and cuts down on breaks. Conveyor belts move raw stuff, finished food, or packaging. Choosing the wrong one can cause big problems, like safety issues or rule-breaking. This article lists the top five mistakes people make when picking food processing conveyor belts. It also shares how to avoid them using Uyang Belting’s awesome thermodrive belts.

Mistake 1: Forgetting About Cleanliness

Why Cleanliness Matters in Food Processing

Keeping things clean in food processing is important. Conveyor belts must be spotless to meet high safety rules. If they’re not, germs can grow and ruin food. This can lead to sick customers, product recalls, or even legal trouble. Belts with seams, fabric, or tricky designs can trap dirt and germs, making them hard to clean.

Solution: Pick Clean and Safe Conveyor Belts

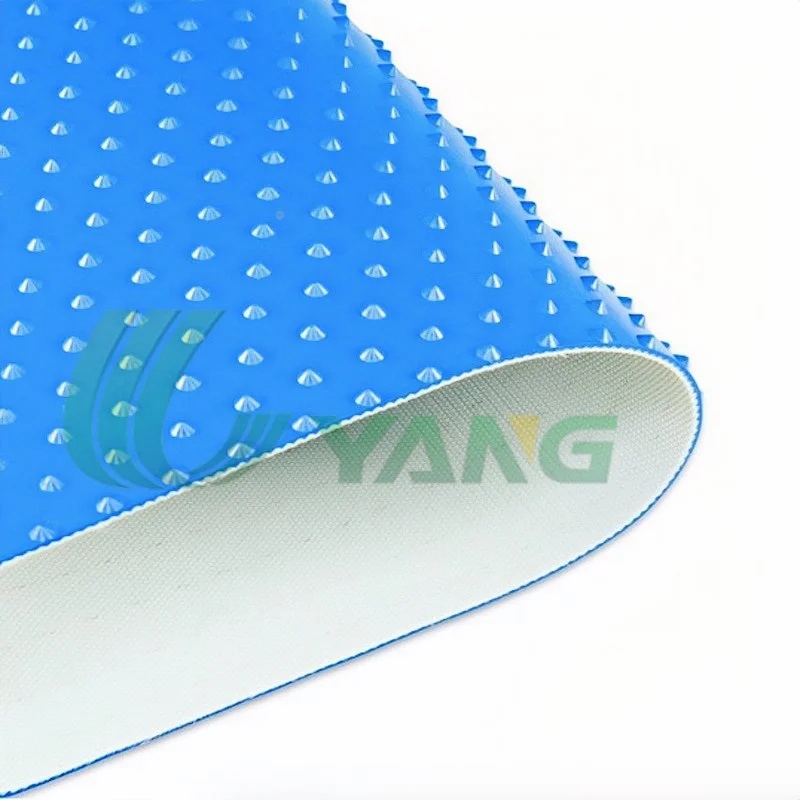

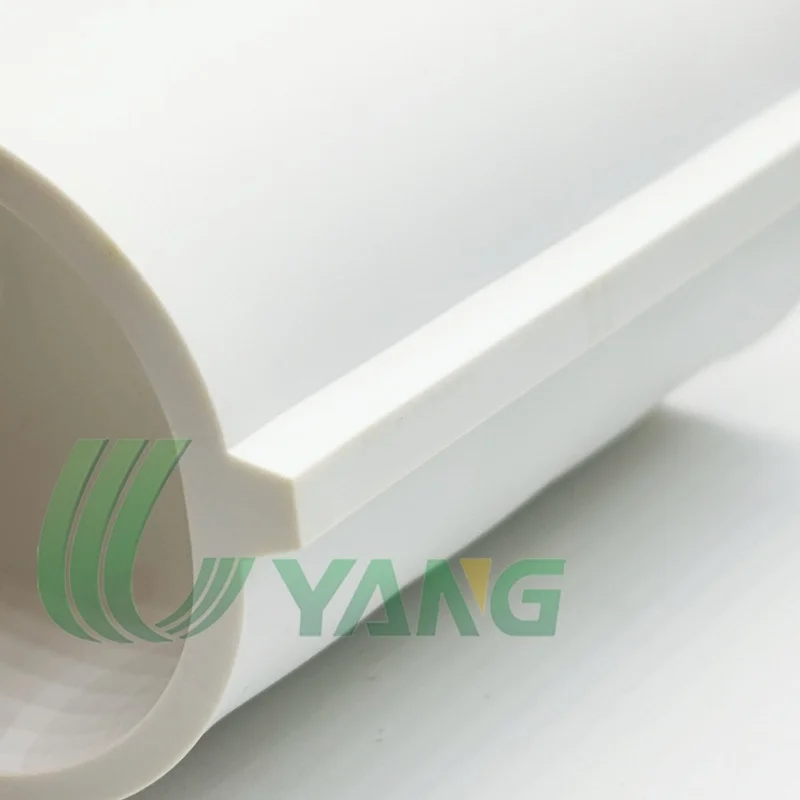

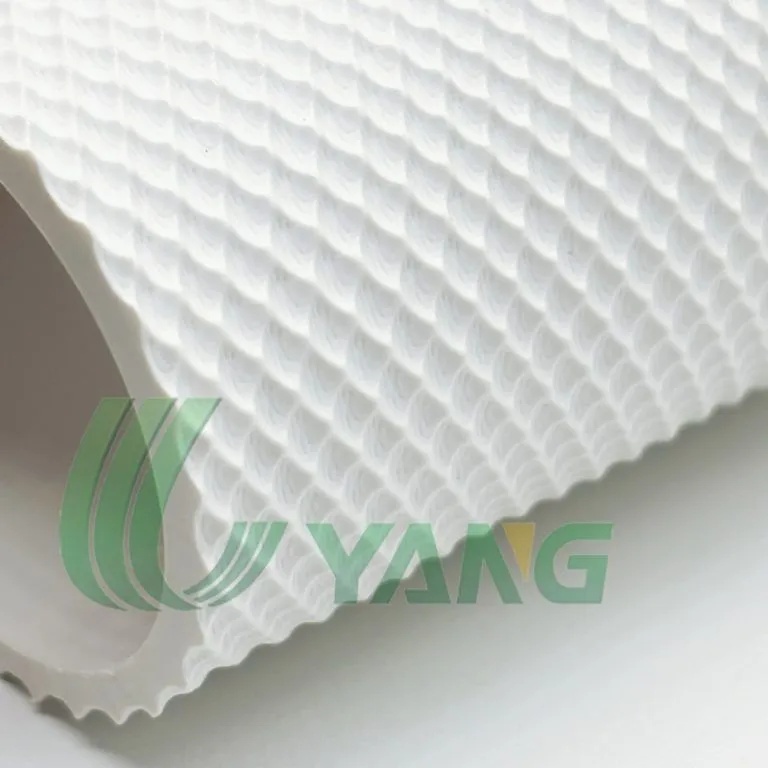

To keep your food safe, choose belts that are easy to clean and don’t let germs stick. Uyang Belting’s thermodrive belts are perfect for this. They’re made from a smooth, solid plastic called thermoplastic polyurethane (TPU). This means no gaps for germs to hide. You can wash them with strong water, hot water, or cleaning chemicals. They meet tough safety rules, like those from the FDA and EU, keeping your food safe and clean.

Mistake 2: Ignoring the Work Environment

How the Environment Affects Conveyor Belts

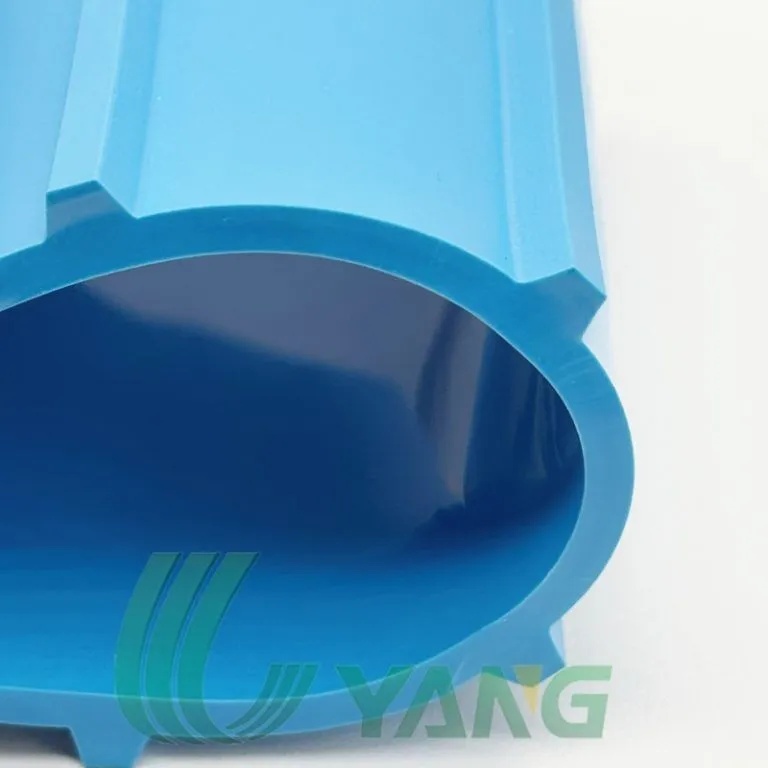

Food processing places can be hot, cold, wet, or full of chemicals. If a belt isn’t made for these conditions, it can break down fast. This causes stops in work and costly fixes. Whether you’re handling frozen food, dairy, or baked goods, the belt needs to stay strong in your specific setup.

Solution: Choose Belts for Your Environment

Pick a belt that can handle your workplace’s heat, cold, or wet conditions. Uyang Belting has lots of belts made for different environments. For cold places, their thermodrive belts resist water damage. For hot spots, they stay tough without bending or breaking. These belts keep your work going smoothly, no matter the conditions.

Mistake 3: Not Thinking About Easy Cleaning

Why Easy Cleaning Is Important

A conveyor belt that’s hard to clean can slow down your work. Dirty belts can spread germs, raise costs, and stop production for cleaning. This is a big deal for foods like ready-to-eat meals that touch the belt directly. Germs on belts can make people sick, which is a huge problem.

Solution: Go for Easy-to-Clean Belts

Choose belts that make cleaning quick and simple. This saves time and keeps food safe. Uyang Belting’s thermodrive belts are great for this. Their smooth surface doesn’t soak up water or oils. You can clean them fast, which cuts down on work breaks and cleaning costs. These belts are perfect for places that need to stay super clean.

Mistake 4: Not Caring About Belt Strength

The Cost of Weak Belts

Picking a cheap belt might seem smart, but it can cost more later. Weak belts wear out fast, break often, and need lots of fixes. This stops work and hurts your profits. Belts that can’t handle daily use cause big delays and extra expenses.

Solution: Pick Strong, Long-Lasting Belts

Choose belts that are tough and last a long time. Uyang Belting’s thermodrive belts are built to be super strong. They handle tough conditions without wearing out quickly. Even though they might cost more at first, they save money by lasting longer and needing fewer repairs.

Mistake 5: Not Thinking About Custom Needs

Why Custom Belts Matter

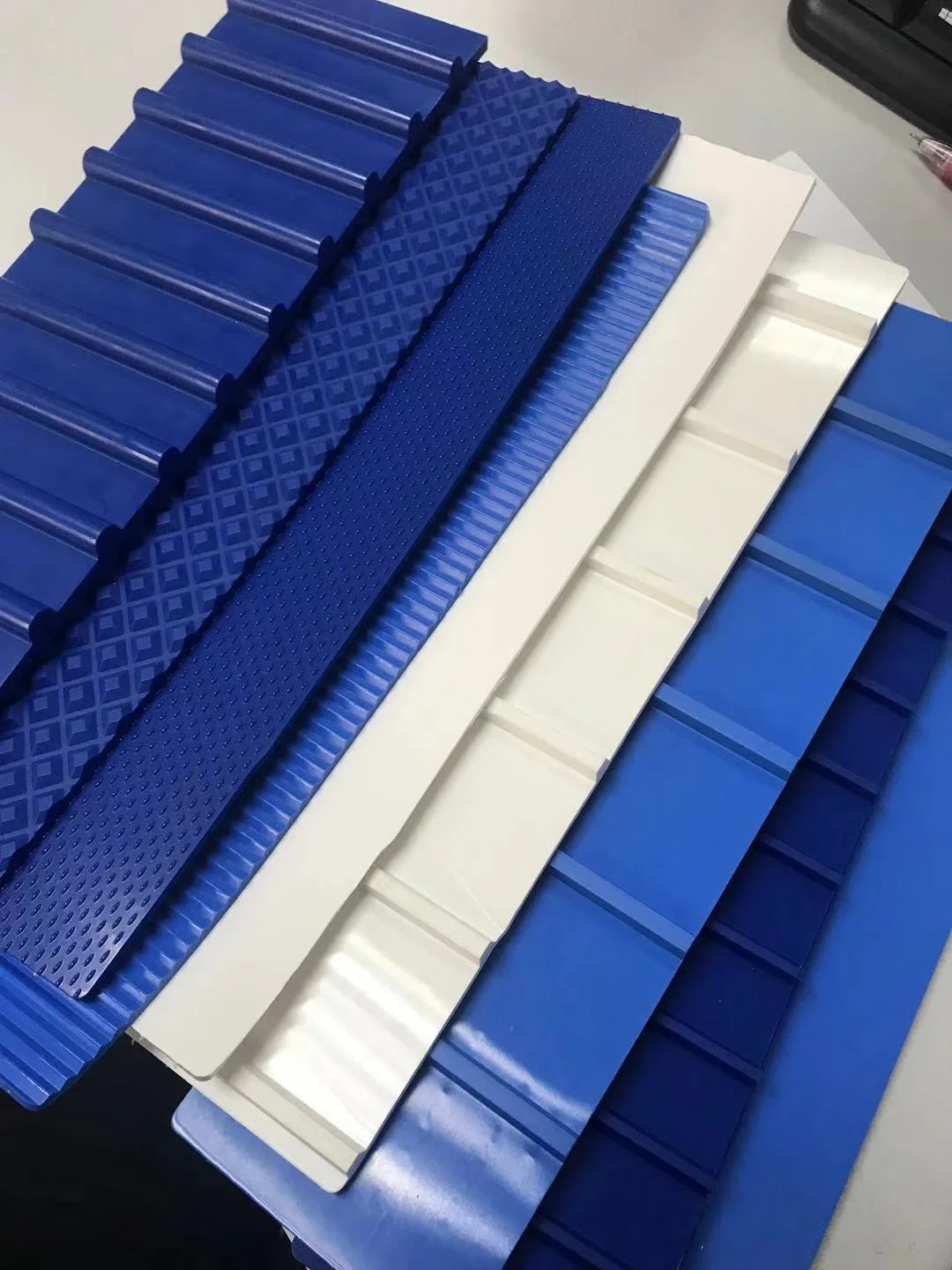

Every food processing place is different. The food you make, your setup, and safety needs all vary. A one-size-fits-all belt might not work well. For example, some foods need special textures or colors on the belt to spot dirt easily. A belt that doesn’t fit your needs can cause problems.

Solution: Choose Belts You Can Customize

Pick belts that can be made to fit your exact needs. Uyang Belting offers thermodrive belts that can be changed to match your work. Need a special texture, thickness, or color like blue to spot dirt? They can do it. These custom belts make your work safer and more efficient.

How to Avoid These Mistakes: Top Tips for Picking the Right Belt

Work with Experts

To get the best belt, team up with a supplier who knows their stuff. Uyang Belting has over 20 years of experience. They give great advice and make belts that fit your needs perfectly.

Check Your Needs Carefully

Before picking a belt, think about what your production line needs. Look at things like heat, wet conditions, food type, and how much you produce. Knowing this helps you choose a belt that works well and avoids problems.

Spend on Quality

Cheap belts might save money at first, but they can cost more later. Invest in high-quality belts like Uyang Belting’s thermodrive belts. They’re safe, strong, and last a long time, making them a smart choice for your business.

Conclusion

Picking the right conveyor belt is key to keeping food processing safe and smooth. By avoiding these five mistakes—forgetting cleanliness, ignoring the environment, skipping easy cleaning, choosing weak belts, and not customizing—you can make your work better. Uyang Belting’s thermodrive belts are a great choice. They’re clean, tough, and can be made to fit your needs. They help keep food safe, cut costs, and make your bakery or food plant run better. Contact Uyang Belting today to find the perfect belt for your business.

FAQs

Q1. What makes Uyang Belting’s thermodrive belts great for food processing?

A: Thermodrive belts have a smooth, solid surface that’s easy to clean. They stop germs and meet FDA, EU, and USDA safety rules, keeping food safe.

Q2. How often should food processing conveyor belts be cleaned?

A: Clean belts after every work shift to remove dirt or germs. For extra clean places, do a deep clean weekly with steam or cleaning liquids.

Q3. Can Uyang Belting’s thermodrive belts be customized for my needs?

A: Yes, Uyang Belting can change thermodrive belts to fit your work. You can pick textures, thicknesses, or colors like blue to spot dirt easily.