Introduction

In tire manufacturing, speed and safety decide how well a factory runs. Conveyor belts carry raw rubber, move semi-finished tires, and send finished ones to packaging. If belts stop, the whole line slows down.

Many plants now look for suppliers that really understand their challenges. uyang belting has built strong trust in this field. With years of practice and a focus on belts that can take heat, pressure, and wear, the company helps factories stay on track.

The Role of Conveyor Belts in Tire Manufacturing

Improving material flow across production stages

Tire production has many steps. Rubber mixing, calendaring, bead building, curing, and inspection. All these need smooth and steady transfers. A good belt system keeps the flow steady. If rubber sits still because a belt broke down, delays build up fast. Lost time means lost money.

Enhancing worker safety and reducing risks

Hot and sticky rubber is tough to handle by hand. Belts with stable grip lower the chance of slippage. This reduces the need for workers to touch the material directly. Fewer accidents and fewer close calls also mean the factory runs more steadily.

Minimizing downtime with reliable systems

Every hour of downtime may mean hundreds of tires unfinished. Belts that hold their shape and don’t peel or split help avoid such waste. One maintenance manager once said, “The best belt is the one you never notice.” If it runs quietly in the background, then it’s doing its job.

Why Tire Factories Need Specialized Conveyor Solutions

Handling heavy and abrasive rubber compounds

Rubber is full of oils, carbon black, and other additives. These wear down weak belts very fast. Strong belts designed for this job last longer and keep their grip even under constant load.

Maintaining stability under high temperature processes

Curing presses reach up to 200°C. Belts near this area must take high heat without bending or shrinking. Cotton canvas PU belts are strong yet flexible, making them a good match for these conditions.

Reducing contamination and ensuring product consistency

Poor belts often fray at the edges. Small fibers or loose parts can fall into the rubber sheet. This can lead to quality problems in the final tire. Belts from UYANG BELTING are made with sealed edges, lowering this risk and giving more consistent results.

UYANG BELTING Cotton Canvas PU Conveyor Belts for Tire Industry

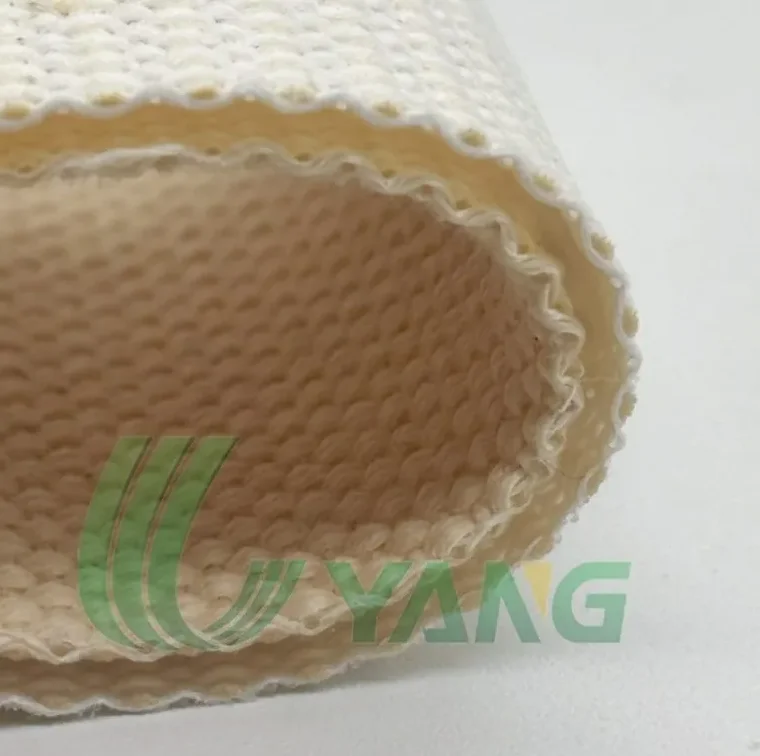

2.5mm Cotton Canvas PU Conveyor Belt features and benefits

ที่ 2.5mm Cotton Canvas PU Conveyor Belt is often used in medium-duty parts of tire production. The cotton canvas layer gives it strength, while the PU coating resists oil and damage. At 2.5mm, it is light to install but tough enough to handle daily work. Many factories use it to move green tires before curing. At this stage, the line needs both stability and clean surfaces.

3.0mm Cotton Canvas PU Conveyor Belt features and benefits

For heavier tasks, the 3.0mm Cotton Canvas PU Conveyor Belt is often chosen. The thicker design adds more strength and control. It works well with larger or heavier tires and in areas with higher friction. Its cotton canvas keeps it stable, while the PU top layer prevents sticking. Many maintenance teams say this belt lasts longer than old rubber belts, which means fewer changes and less downtime.

Comparing cotton canvas PU belts with traditional rubber belts

Rubber belts are cheap and common, but they swell with oil and often peel apart over time. Cotton canvas PU belts don’t have this problem. They keep their form, resist moisture, and stay cleaner. This leads to fewer stoppages and lower overall costs. For a manager balancing daily targets, that’s a big relief.

Key Advantages of Cotton Canvas PU Belts in Tire Production

Superior strength and dimensional stability

The cotton canvas acts like a backbone. It stops the belt from stretching and keeps it aligned. This helps reduce tracking problems and keeps conveyors running straight.

Smooth surface for clean and efficient conveying

The PU surface is smooth and easy to clean. Rubber sheets slide without sticking, and workers spend less time washing belts. More time on production, less time on cleaning.

Long service life with reduced maintenance costs

These belts don’t cut or wear down as easily. They last longer than many standard belts. Even if the starting price is higher, fewer replacements mean money saved in the long run.

Customization Options to Match Tire Factory Needs

Thickness and surface variations for different tire lines

Not all lines are the same. Small passenger tires and large truck tires need different support. UYANG BELTING can provide belts with different thickness and textures to suit each case.

Color and finish options for safety and visibility

Blue or green belts are easy to see inside the plant. This makes it simpler to find dirt or defects. Inspectors can check quality faster when the surface stands out.

Compatibility with various conveyor configurations

Factories may use flat lines, inclined belts, or special layouts near curing presses. Cotton canvas PU belts can be made to match these systems. That flexibility makes upgrades easier without stopping the line for long.

Global Market Trends Supporting Advanced Conveyor Belts

Growth of polymer-based belts in automotive manufacturing

Reports show polymer belts like PU and TPE are rising fast. In 2024, the conveyor belt market was worth USD 5.7 billion. By 2034, it is expected to hit USD 8.2 billion. Tire plants are one of the key drivers of this growth.

Rising demand for energy-efficient and safe factory systems

Factories are under pressure to cut energy waste and keep workers safe. Belts that need fewer replacements and less manual help make a clear difference. They save energy and lower accident risks.

Increasing preference for long-lasting, hygienic belt materials

While cleanliness is often linked with food plants, tire makers benefit too. Belts that stay clean produce fewer defects and less waste. The global shift toward durable and easy-to-clean materials supports this trend.

Conclusion

Conveyor belts don’t often get attention, but they decide how smooth a factory runs. With strong belts, tire plants see higher output, fewer accidents, and lower costs.

UYANG BELTING has proved itself as a reliable partner. Their PU cotton canvas belts fit the real demands of tire production. From the lighter 2.5mm Cotton Canvas PU Conveyor Belt to the stronger 3.0mm Cotton Canvas PU Conveyor Belt, the products keep plants moving without delays.

คำถามที่พบบ่อย

Q1: What makes cotton canvas PU conveyor belts suitable for tire factories

They mix the strength of canvas with the smoothness of PU. This makes them durable, clean, and steady under tough working conditions.

Q2: How do UYANG BELTING belts reduce downtime in production

They last longer, need less cleaning, and stay aligned better. That means fewer stops for fixing or replacing.

Q3: Can these belts be customized for different tire manufacturing lines

Yes. UYANG BELTING offers belts in different thicknesses, colors, and surfaces. This allows them to fit both small passenger tire lines and heavy-duty truck tire lines.