Treadmill belt noise can disturb workouts and point to mechanical troubles. This thorough guide examines typical causes of operational noise, including misalignment, poor lubrication, or worn parts. It offers practical fixes and preventative care tips to keep your machine running quietly and smoothly. Addressing these problems quickly can prolong your treadmill’s life and ensure a comfortable exercise experience.

Common Causes of Treadmill Belt Noise

Could Misalignment Be the Issue?

Belt misalignment often sparks treadmill noise. When the belt drifts off-center, it scrapes against edges or components, causing squeaks or scraping sounds. This problem usually stems from uneven tension or faulty setup. Keeping the treadmill on a flat surface aids in prevention. Checking alignment regularly also helps. Misalignment can cause uneven wear, worsening treadmill function.

Is Poor Lubrication a Concern?

Low lubrication between the deck and belt heightens friction. This leads to noise and faster wear. Friction over time burdens the motor and other parts. Using a top-notch lubricant made for treadmills is crucial. Regular application ensures quiet, smooth performance. Without adequate lubrication, the belt may overheat, leading to lasting damage.

Could Wear and Tear Be to Blame?

Treadmill belts degrade naturally with use. Splits, frayed edges, or worn patches create uneven motion and louder sounds. Regular inspections spot these issues early. Swapping out worn belts prevents further harm. A damaged belt can stress the motor, causing expensive repairs.

Is Debris Buildup a Factor?

Dust and grime gather under the belt, especially in homes. These particles boost friction or harm the belt. Routine cleaning cuts down noise and extends belt life. Debris can also mar the deck’s surface, adding to wear.

Diagnosing the Source of the Noise

How Can You Check for Visible Wear?

Inspect the belt closely for splits, fraying, or uneven spots. These signs suggest wear that may trigger noise. Visible damage often calls for belt replacement. Regular checks catch small problems before they grow.

Are Alignment Problems Noticeable?

Look for side-to-side belt shifts during use. See if the belt looks off-center while operating. These clues indicate alignment issues. Quick fixes prevent further trouble.

Run the treadmill at a slow pace. Watch if the belt stays centered. If it veers to one side, adjustments are needed. Persistent drifting can harm belt edges.

How Do You Gauge Lubrication Levels?

Check for excessive friction between deck and belt. A dry surface signals low lubrication. Using the right lubricant fixes this. Squeaks or grinding during use often mean poor lubrication. Fast action prevents damage to the motor and deck.

Could Rollers or Bearings Be the Cause?

Examine rollers and bearings for issues. Check for stiffness or odd sounds when turning them by hand. Faulty rollers or worn bearings may need replacing. These parts are vital for quiet, smooth operation.

Effective Solutions for Fixing a Noisy Treadmill Belt

How Can You Fix Belt Alignment?

Adjust the tension bolts at the treadmill’s back. Tighten or loosen them slowly. Run the machine at a low speed while adjusting. Stop when the belt is centered. Correct tension prevents slipping. It also avoids over-tightening, which stresses parts. Check alignment every few sessions to ensure performance.

Why Is Lubricating the Belt Vital?

Lubrication lowers friction between moving parts. This ensures smoother running and longer part life. Use lubricants suggested by the manufacturer to avoid problems. Regular lubrication cuts noise and wear, reducing repair costs.

What Lubricants Work Best?

Silicone-based lubricants suit most treadmills. They last long and reduce friction well. Try Uyang Belting’s specialized lubricants. These are designed for fitness equipment. Avoid petroleum-based products, as they can harm belts.

What Are the Advantages of Quality Lubricants?

High-grade lubricants reduce wear on belts and decks. They cut noise greatly. This leads to lasting performance with less upkeep. Quality lubricants maintain steady viscosity, avoiding residue buildup.

When Should You Replace Worn Belts?

If checks show splits or frayed edges, replace the belt. Worn belts cause noise and mechanical issues. Delaying replacement risks motor damage. Regular inspections help decide when to replace.

Where Can You Find Trustworthy Replacement Belts?

Select high-quality replacement belts for durability. Uyang Belting offers top-notch options. These are built for long-term use in various treadmill models. Confirm compatibility with your treadmill’s specs.

How Do You Install New Belts Properly?

Follow the manufacturer’s instructions closely. Set correct alignment and tension during installation. This ensures quiet, efficient operation. Poor installation can cause instant noise issues. Verify tension settings after installation.

Preventative Maintenance to Avoid Future Noise Issues

Why Are Regular Cleaning and Inspections Essential?

Keeping your treadmill clean boosts performance. Dust and debris collect under the belt. This causes friction and damage. Regular cleaning prevents these problems. It also extends belt life.

Unplug the treadmill for safety. Lift the belt gently. Use a vacuum or soft cloth to clear debris. This easy step cuts noise and wear. Clean monthly or after heavy use.

Why Is a Regular Lubrication Schedule Key?

Lubrication reduces friction between deck and belt. Low lubrication increases wear and noise. A steady schedule improves efficiency. It also lowers sound. Lubricate every three months or after 40 hours of use. Choose treadmill-specific silicone lubricants for top results. Specialized products ensure steady performance.

How Often Should You Check Roller Bearings and Drive Motors?

Roller bearings and drive motors need frequent inspections. Faulty parts cause noise and affect performance. Check them every six months. Look for stiffness or strange sounds. Early detection avoids bigger problems. Replace worn parts quickly to keep operation quiet.

Why Choose Uyang Belting Products for Your Treadmill?

What Makes These Products Long-Lasting?

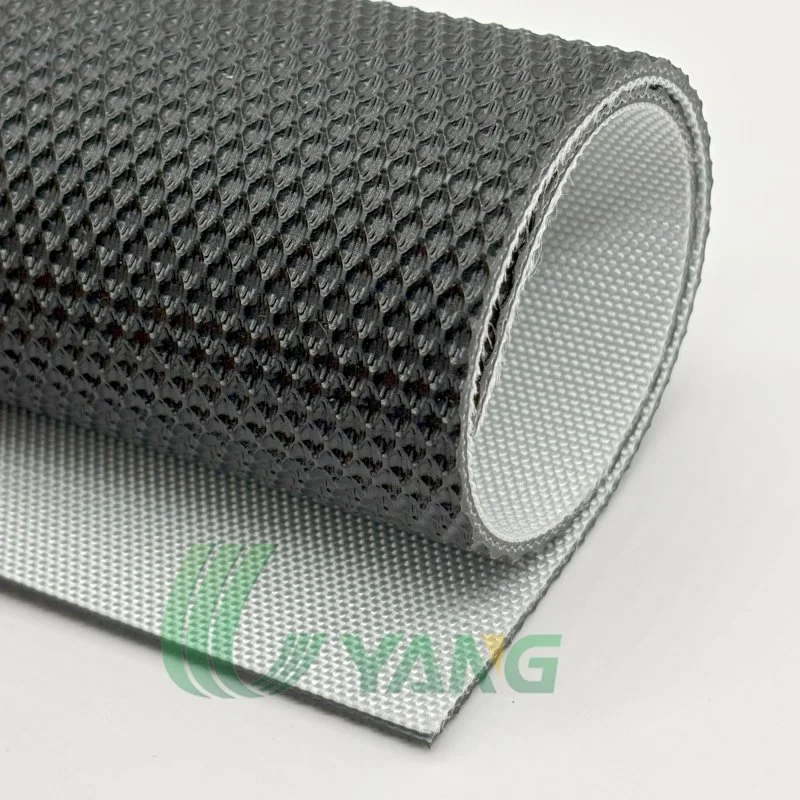

Durable treadmill belts ensure dependability. Advanced materials resist wear. Polymer-based belts, like polyurethane or rubber, offer strength and flexibility. They suit heavy-duty use. These belts handle tough workouts, reducing replacement needs.

Are Custom Solutions Available for Different Models?

Each treadmill model has specific needs. Tailored belts ensure compatibility and performance. With over 20 years of expertise, specialized providers offer custom options. These suit various treadmill types. Check your treadmill’s manual for belt specs.

How Does Expert Support Ease Installation?

Installing a new belt can be tricky. Expert advice ensures proper setup. This covers alignment and tension adjustments. Providers with lifetime technical support improve performance. They handle issues fast. Contact support for detailed installation guidance.

Additional Maintenance Tips

How Can You Track Belt Tension?

Monitor belt tension often. A loose belt slips, causing noise. An overly tight belt stresses the motor. Adjust tension bolts for a slight lift (about 2–3 inches) when pulling the belt. Regular tension checks maintain performance.

What Tools Are Useful for Maintenance?

Keep a screwdriver, Allen wrench, and soft cloth ready. These aid in adjustments and cleaning. A vacuum with a nozzle attachment helps remove debris. Proper tools make maintenance simpler and more effective.

How Can You Avoid Motor Overload?

Avoid running the treadmill at high speeds for long periods. This stresses the motor and belt. Use suitable speeds for your workout. Regular lubrication and cleaning ease motor strain. A well-kept belt prevents overload issues.

FAQs

Q1: How often should I lubricate my treadmill belt?

A: Lubricate every three months. Or do so after 40 hours of use. This ensures top performance.

Q2: Can I use standard lubricants on my treadmill?

A: No, stick to silicone-based lubricants recommended by the manufacturer. Standard products may cause damage.

Q3: What signs show roller bearings need replacing?

A: Odd noises or stiffness when rotating by hand suggest problems. Fix these quickly to prevent further issues.