- Rumah

- Produk

- Industri & Aplikasi

- Mengenai

- Hubungi

MS

MS

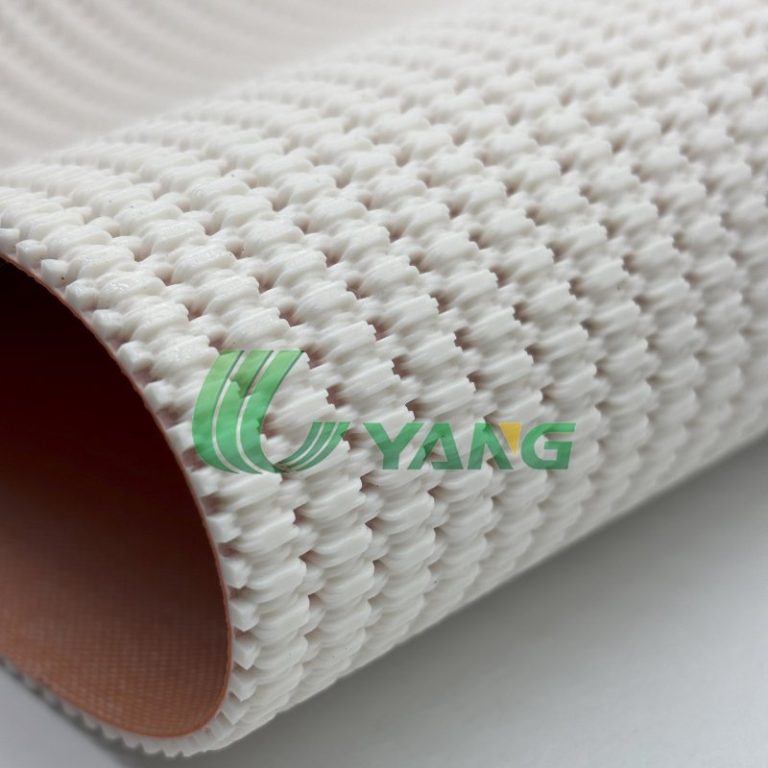

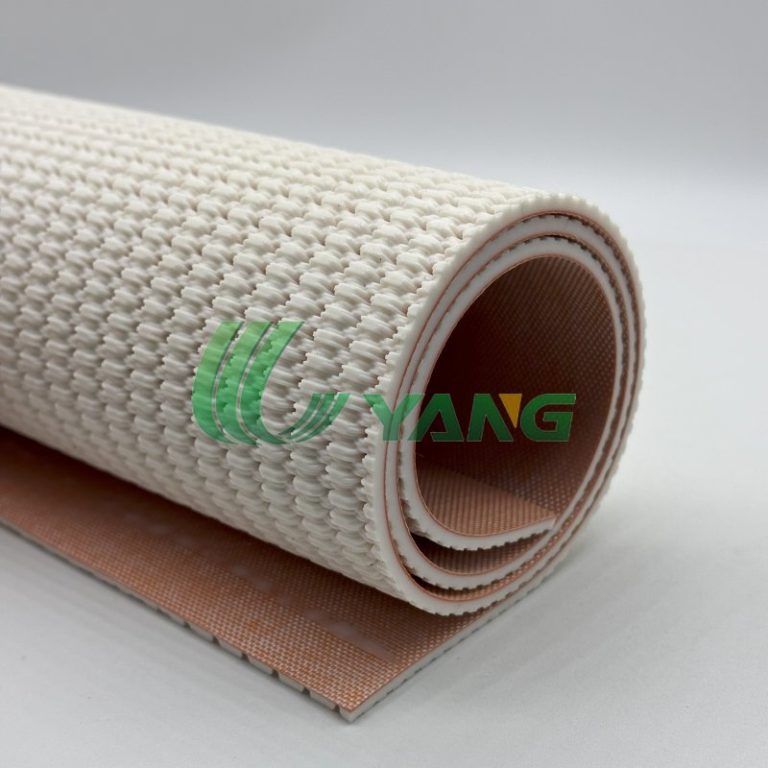

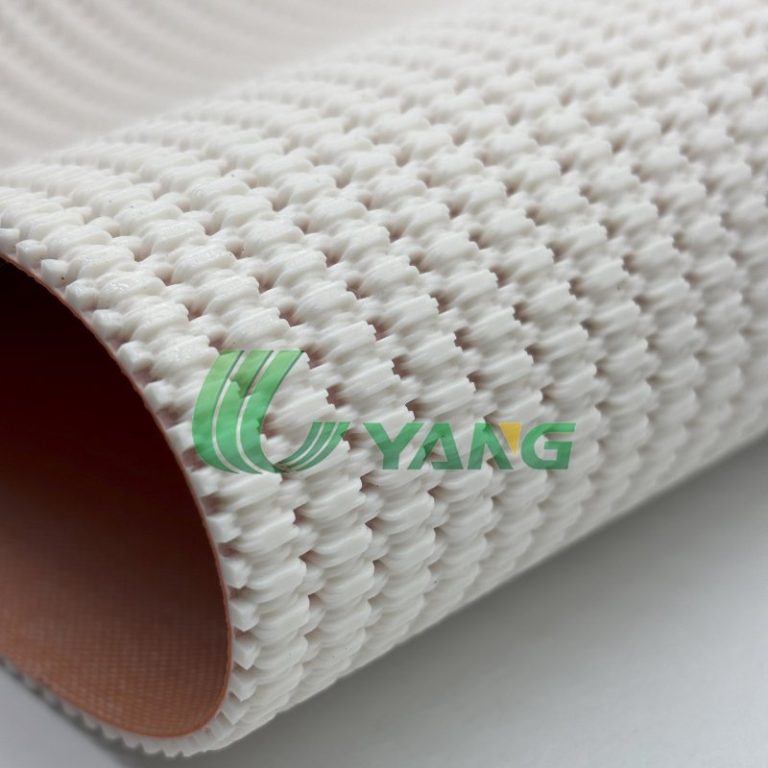

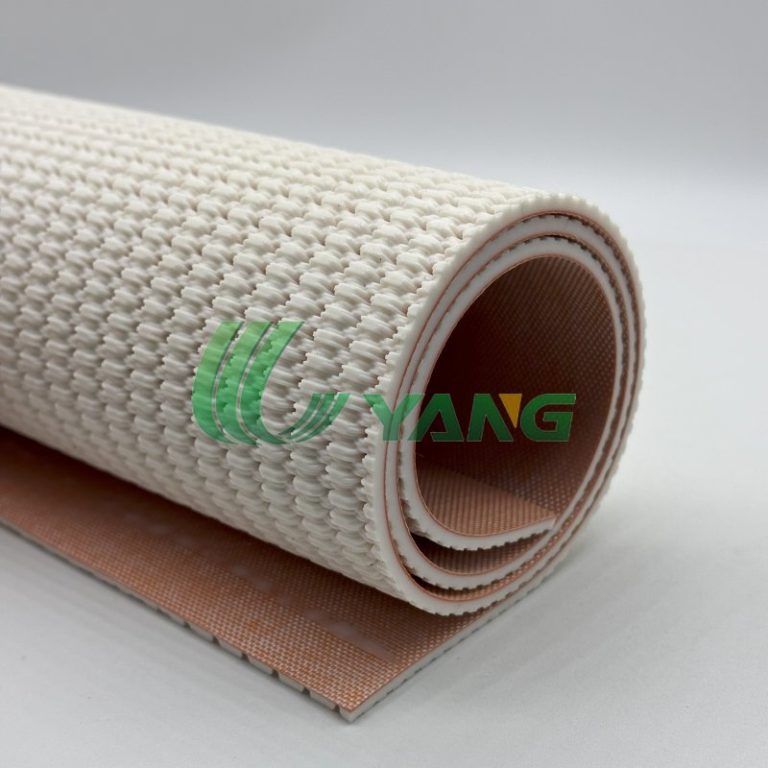

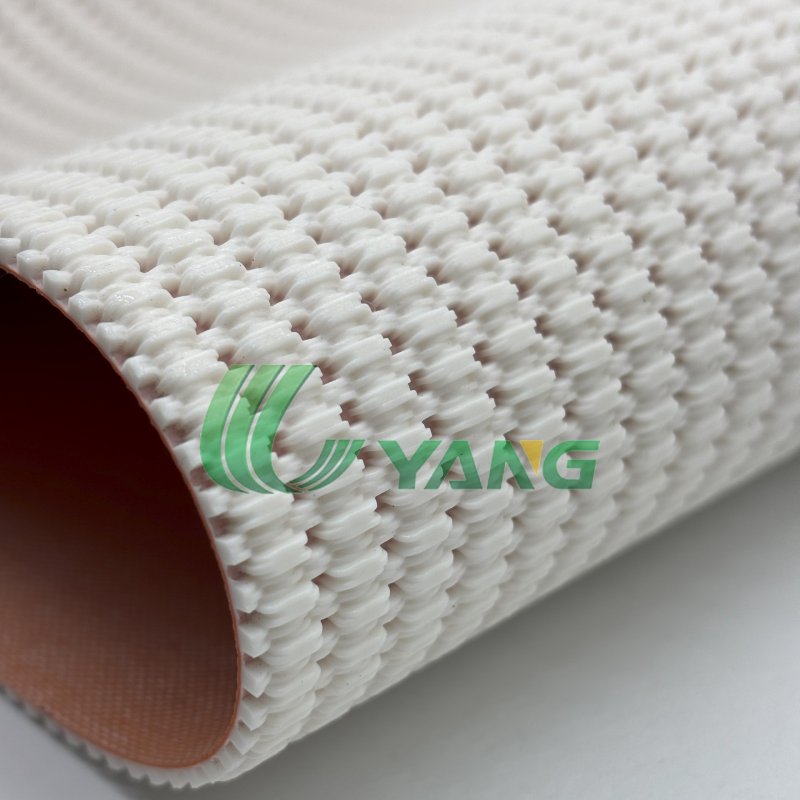

UYANG BELTING shallow-grass (浅草纹) silicone molds accurately transfer the belt’s anti-slip texture into hot-press or vulcanized splice areas, ensuring consistent grip, appearance and cleanability across the entire conveyor surface.

UYANG BELTING shallow-grass (浅草纹) silicone molds accurately transfer the belt’s anti-slip texture into hot-press or vulcanized splice areas, ensuring consistent grip, appearance and cleanability across the entire conveyor surface.

Key benefits

Texture continuity — reproduces the shallow-grass pattern at the splice so there’s no change in grip or product handling.

Durable & heat-resistant — made from high-temperature silicone suited for repeated hot-pressing and vulcanizing cycles.

Professional, hygienic finish — produces smooth, low-profile joints that match the rest of the belt visually and functionally, reducing product catch points and easing cleaning.

Typical specifications & options

Material: high-temperature silicone (food-grade options on request)

Pattern: standard shallow-grass pitch/depth (custom pattern matching available)

Sizes: standard sheets or custom cut to belt width and splice length

Thickness: engineered for optimal pattern transfer under recommended press settings

Compatibility: for PVC and PU conveyor belts with diamond/anti-slip surfaces.

How it’s used (quick steps)

Prepare belt ends—clean and trim to even edges.

Insert splice film (if used) and align the belt ends in the hot-press.

Position the shallow-grass silicone mold over the splice area with the patterned side facing the belt.

Apply heat and pressure per belt/splice press parameters.

Allow to cool; remove mold and inspect the pattern transfer.

Finish edges and test the joint under working load.

Aplikasi

Factory splices and on-site repairs for diamond-top PVC/PU belts in food, packaging, logistics, and light industry.

Any production line where consistent anti-slip performance and uniform appearance across splices are required.

Why choose our shallow-grass silicone molds

Precision pattern transfer keeps product handling consistent and reduces rework. Durable, customizable molds help maintain hygienic surfaces and professional-looking splices—saving time and improving line reliability.

Jadual penghantaran yang boleh dipercayai dan sokongan pergudangan.

Harga kompetitif untuk memaksimumkan nilai keseluruhan.

Pelbagai pilihan untuk memenuhi semua segmen pasaran.

Sokongan MOQ yang fleksibel dengan semua jenis barang;

Penyesuaian logo yang diperibadikan pada produk

Sediakan sokongan teknikal dalam talian untuk semua proses penggunaan dan pemasangan produk

Respons pertama yang cepat untuk semua pertanyaan dan soalan

Berikan imej yang berkualiti, video untuk meningkatkan pendapatan jualan

Pengeluaran dan kapal yang cekap dalam masa 15 hari di yang terpantas.

Umumnya 10-15 hari, jika musim puncak, kira-kira 15-20 hari Safter menerima deposit

1. Spesifikasi yang disahkan: ketebalan, warna, plies, ciri, dan industri;

2. Sampel Menghantar: Kami menghantar sampel untuk anda check.or anda menghantar sampel kepada kami jika tali pinggang tersuai.

3. Sahkan Pesanan: Menandatangani Kontrak Jualan Selepas Sampel Disahkan.

4. Deposit: Deposit 30% sebelum pengeluaran besar -besaran.

5. Pengeluaran diatur: Kami akan memproses pengeluaran.

6. Baki pembayaran: Selepas pemeriksaan, baki sebelum penghantaran.

7. Penghantaran: Kami akan menghantar barang ke pelabuhan destinasi.

8. Sahkan bil pemuatan {{url_placeholder_0}} invois {{url_placeholder_1}} list {{url_placeholder_2}} dari asal;