UYANG BELTING blue glossy PVC conveyor belt is primarily used in industries with stringent hygiene requirements, such as food processing, cold chain logistics, beverages, and pharmaceuticals. It is particularly suitable for food-grade production lines exporting to European and American markets

UYANG BELTING blue glossy PVC conveyor belt is primarily used in industries with stringent hygiene requirements, such as food processing, cold chain logistics, beverages, and pharmaceuticals. It is particularly suitable for food-grade production lines exporting to European and American markets

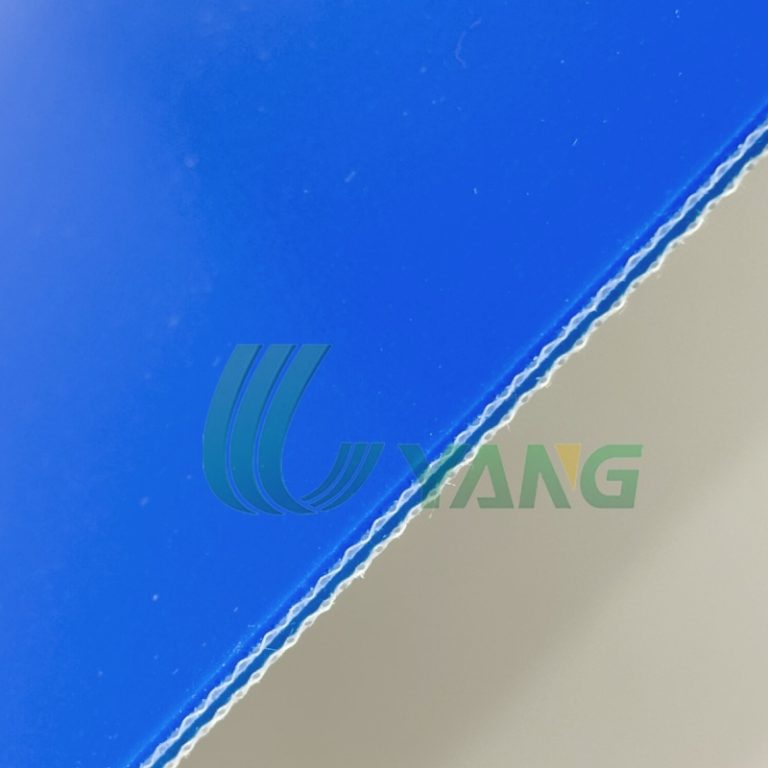

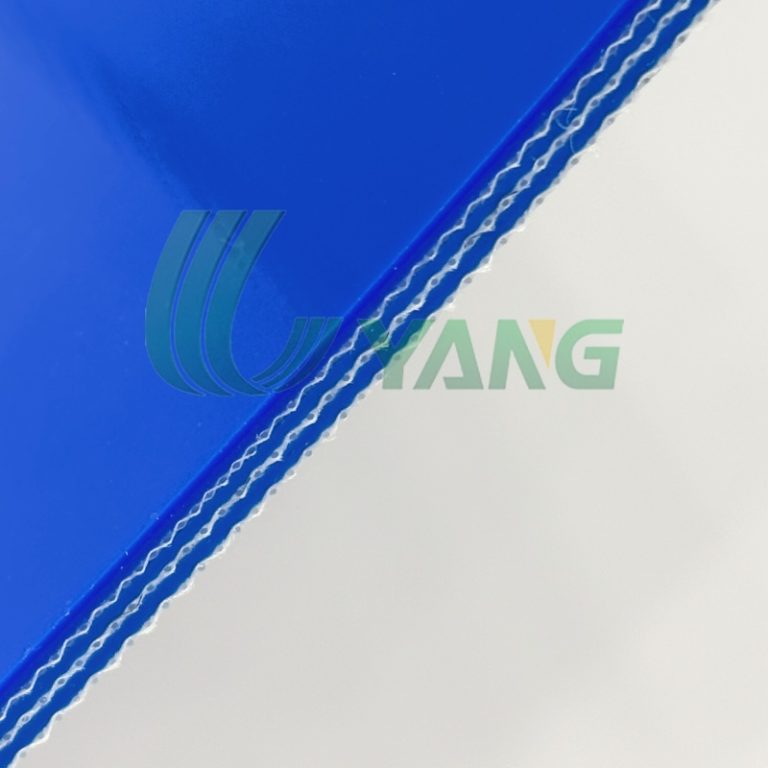

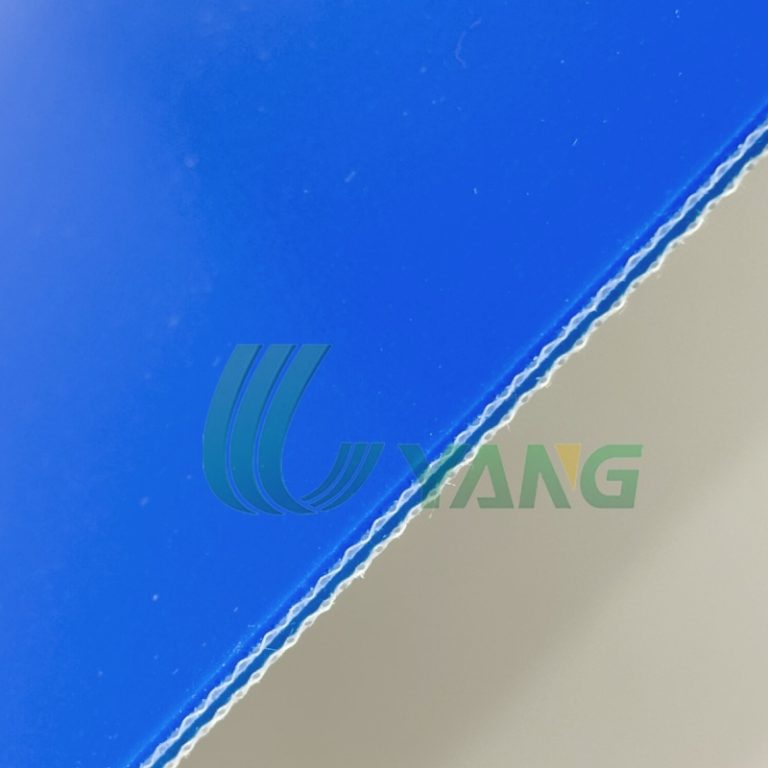

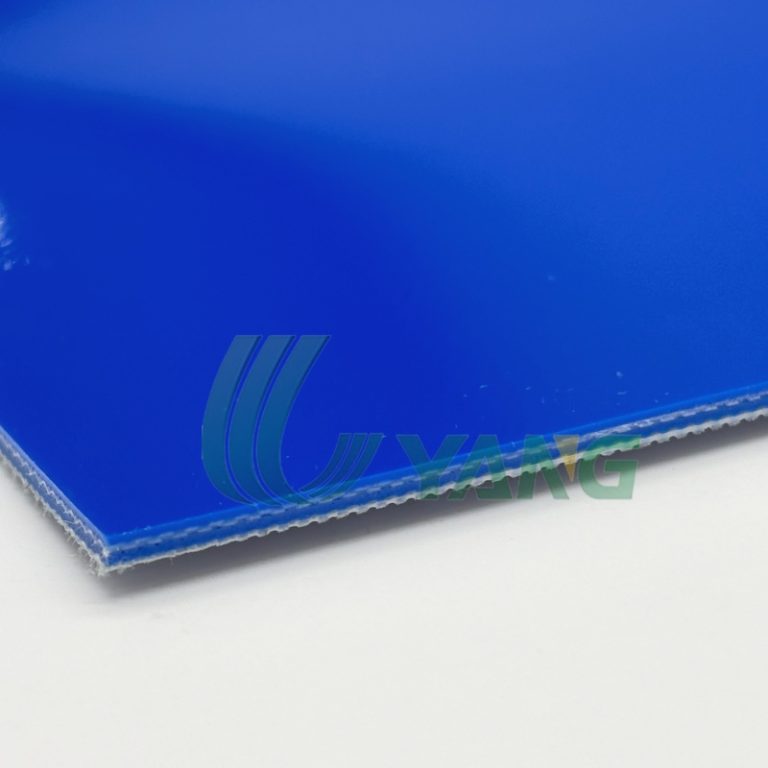

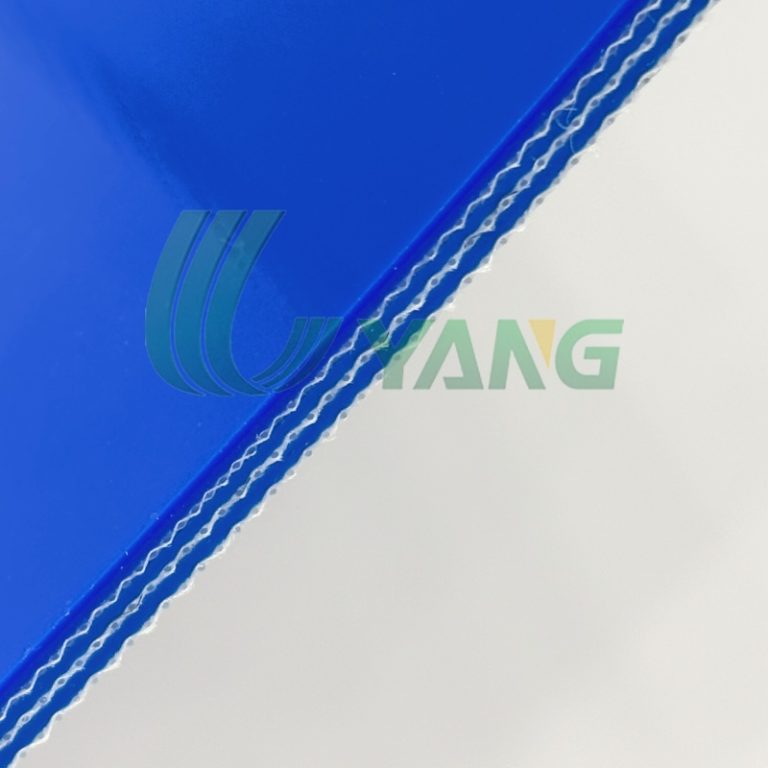

Blue Surface: Enhances foreign object detection & complies with EU/US food industry standards

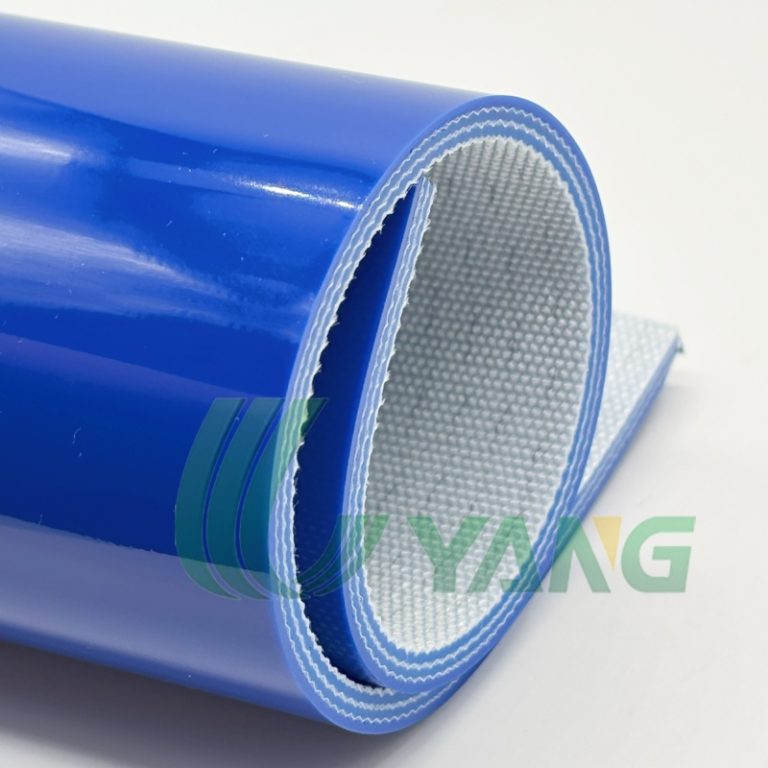

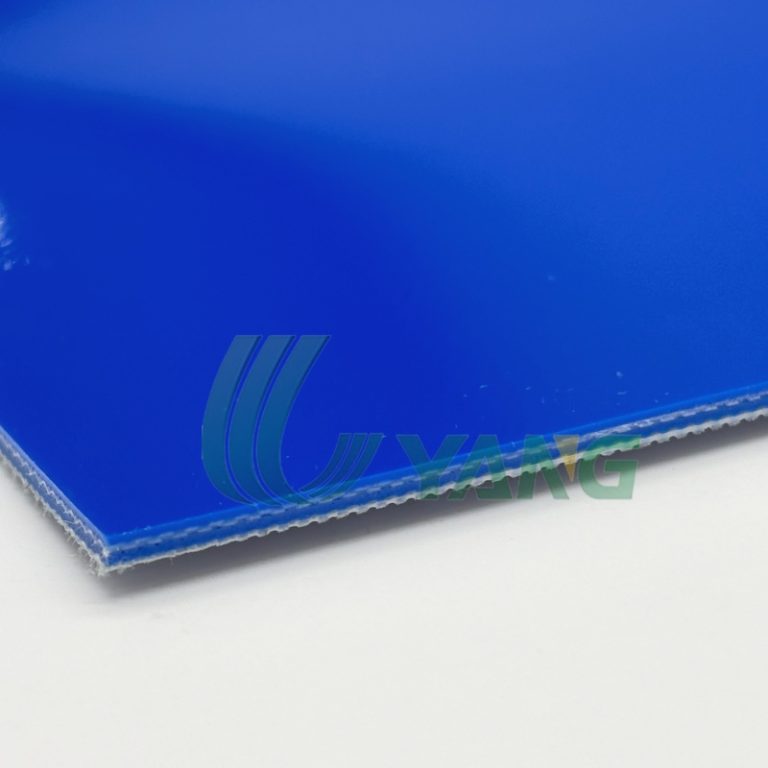

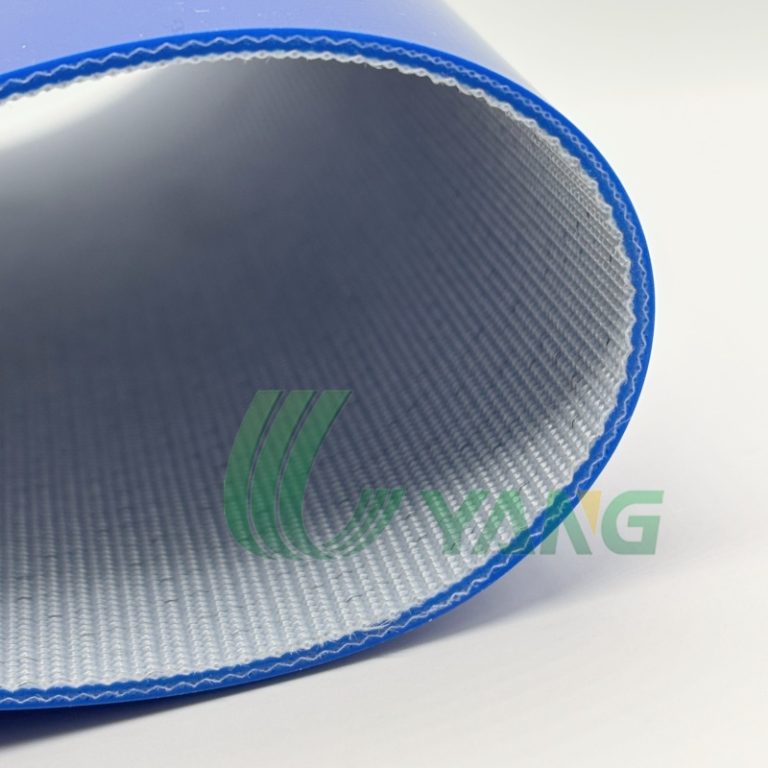

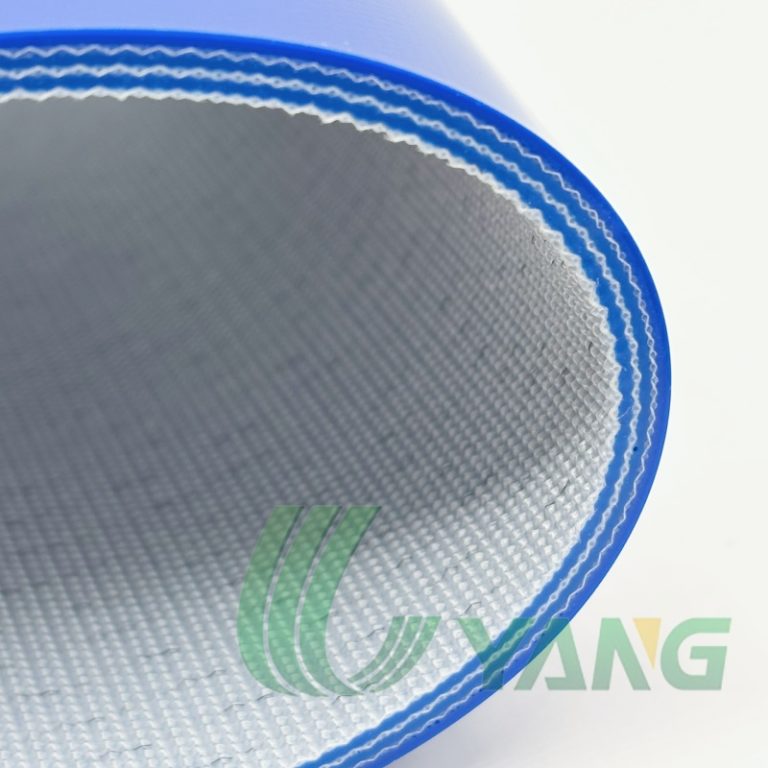

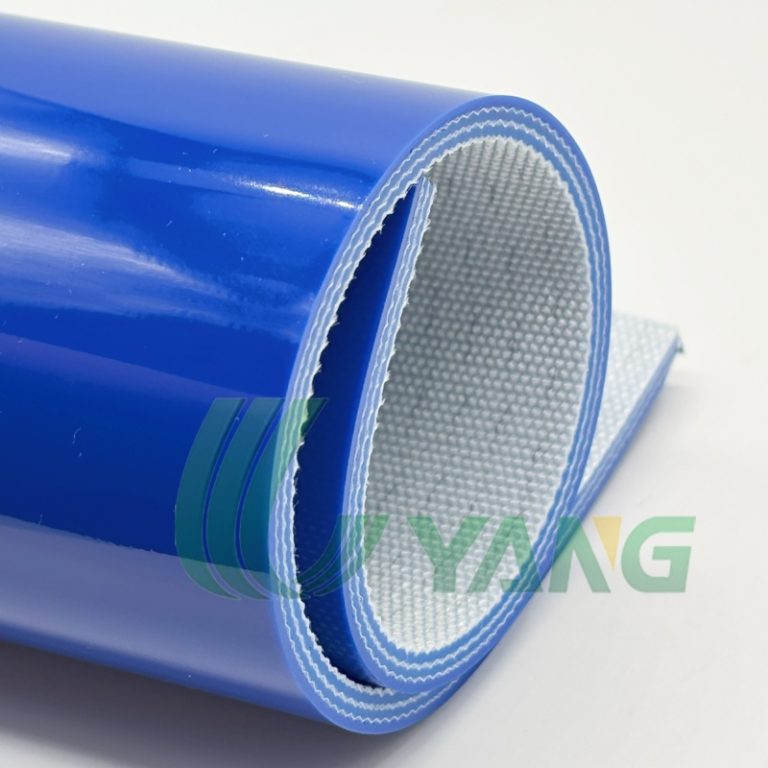

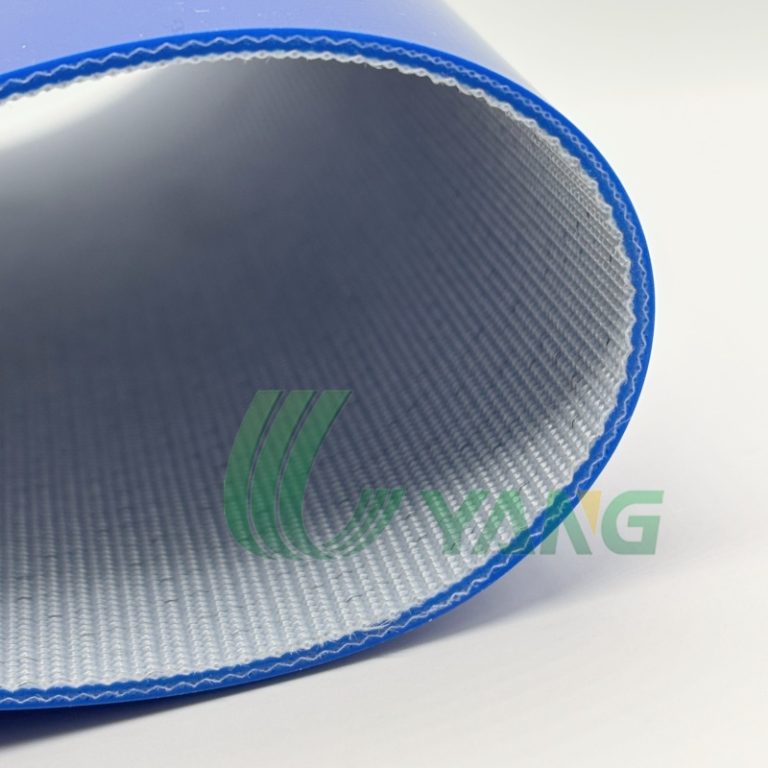

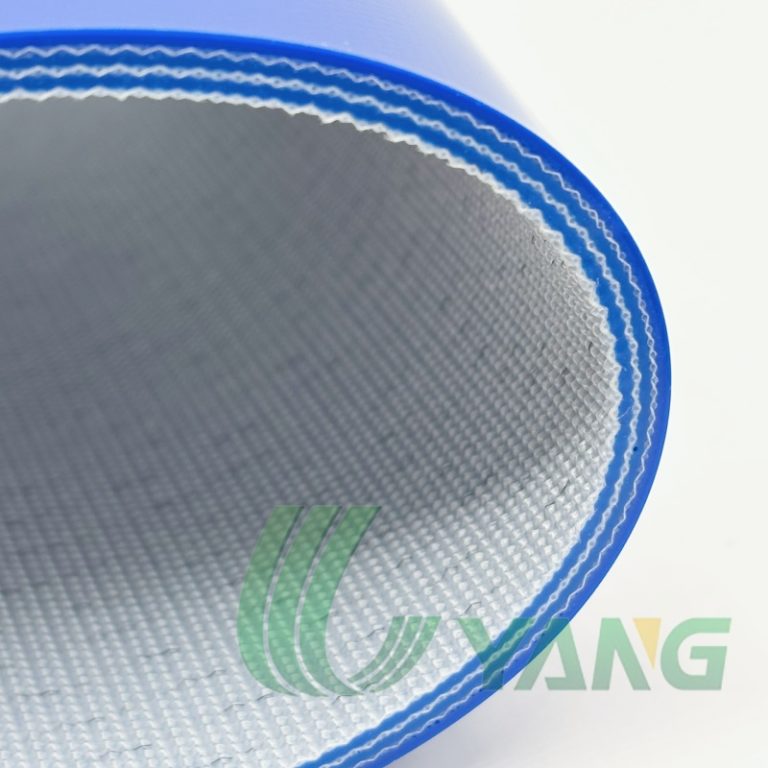

Smooth Structure: Low friction for easy material sliding and cleaning

PVC Material: Food-grade (FDA/EU compliant), oil-resistant, and moisture-proof

Application Environment: Ideal for room-temperature or low-temperature food processing and packaging lines

Blue Smooth PVC Conveyor Belt

Widely used in many industries, especially in food processing. Compared to green belts, blue is often chosen for more stringent food production environments due to the following advantages:

Enhanced Foreign Object Detection: Blue is an unnatural color in most food products, making it easier to spot fragments or contaminants.

Compliance with International Standards: Commonly used in food-grade conveyor belts meeting EU and US regulations, including HACCP and FDA certifications.

Smooth & Easy-to-Clean Surface: Prevents food residue buildup and supports efficient sanitation.

| Industry / Application | Typical Use | Recommended Thickness | Features / Notes |

| Lebensmittelverarbeitung | Meat, seafood, bakery, confectionery, dairy lines | 1.5–3.0 mm | Smooth surface, easy to clean, suitable for food-grade use (FDA/HACCP) |

| Cold-Chain / Frozen Foods | Frozen fruit/vegetable handling, quick-freeze lines | 2.0–3.5 mm | Performs in low temperatures, resists cracking, easy to wash down |

| Beverage & Bottling | Bottle / can conveying, filling, and packing lines | 1.5–2.5 mm | Low friction, stable tracking, compatible with rinsing/sterilization |

| Pharmaceuticals | Vial/tray transport, packaging, and inspection lines | 1.5–2.5 mm | Meets high hygiene standards, easy to sanitize |

| Pet Food & Nutraceuticals | Dry food handling, packaging lines | 1.8–3.0 mm | Food-safe options, good abrasion resistance |

| High-Hygiene Manufacturing | Any production line requiring easy contamination detection | 1.5–3.0 mm | Blue color aids foreign-object detection; smooth for fast cleaning |

Color: Blue (commonly used where foreign-object visibility is required)

Surface: Smooth (low friction, hygienic)

Material: PVC — food-grade formulations available (FDA/EU options)

Temperature Range: Room temperature down to typical cold-chain temps (confirm specific compound)

Cleaning: Compatible with high-pressure washdown and common sanitizers (verify chemical compatibility)

Why blue? Blue rarely occurs in natural foods, so it makes contamination or debris easier to spot during inspection.

Choose thickness by load & environment: lighter thickness (1.5–2.0 mm) for lightweight items and precise handling; heavier (2.5–3.5 mm) for heavier loads or cold/frozen applications.

Certifications: For export to EU/US food lines, specify FDA/EU food-contact grade and HACCP compatibility.

Surface finish: Smooth = easier cleaning and less product sticking; if slight anti-slip is needed, consider textured or matte variants instead.

Zuverlässige Lieferpläne und Lagerunterstützung.

Wettbewerbspreise zur Maximierung des Gesamtwerts.

Verschiedene Optionen, um alle Marktsegmente gerecht zu werden.

Flexibler MOQ -Unterstützung mit allen Arten von Waren;

Personalisierte Logo -Anpassung an den Produkten

Bieten Sie den technischen Online -Support für alle Produktnutzungs- und Installationsprozesse

Schnelle erste Antwort auf alle Anfragen und Fragen

Stellen Sie Qualitätsbilder und Video zur Verfügung, um den Umsatzumsatz zu steigern

Effiziente Produktion und Schiff innerhalb von 15 Tagen am schnellsten.

Im Allgemeinen sind es 10-15 Tage, wenn die Hochsaison etwa 15 bis 20 Tage lang ist, erhält Safter die Kaution

1. Bestätigte Spezifikation: Dicke, Farbe, Lagen, Merkmale und Industrie;

2. Proben Senden: Wir senden Proben für Sie check.

3. Bestätigen Sie die Bestellung: Unterzeichnung des Verkaufsvertrags nach Bestätigung der Stichproben.

4. Kaution: 30% Einzahlung vor der Massenproduktion.

5. Produktion arrangiert: Wir werden die Produktion verarbeiten.

S.

7. Versand: Wir versenden die Waren an den Bestimmungshafen.

8. Bestätigen Sie die Belastungsrechnung {{url_placeholder_0}} Invoice {{url_placeholder_1}} list {{url_placeholder_2}} des Ursprungs;