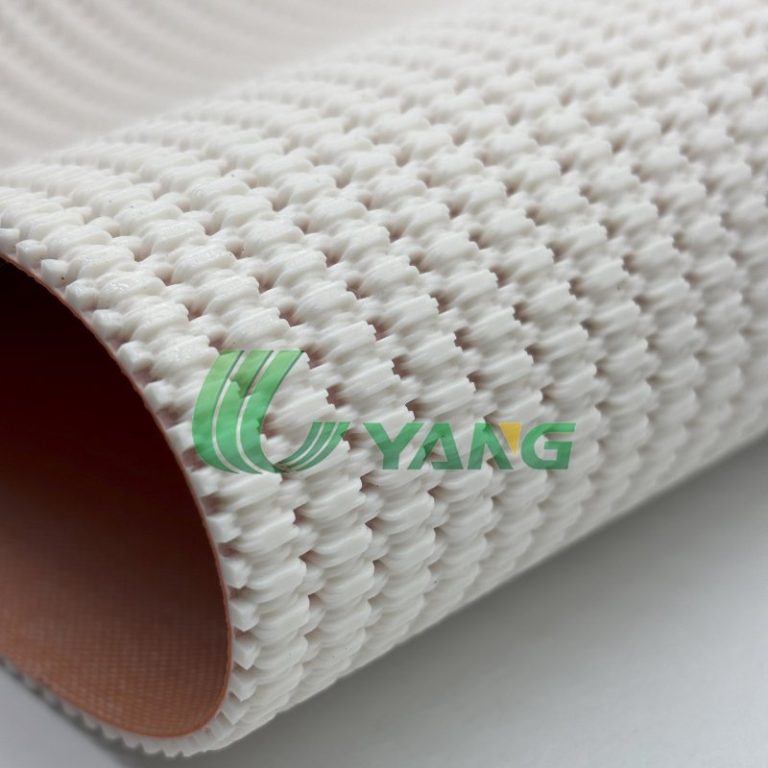

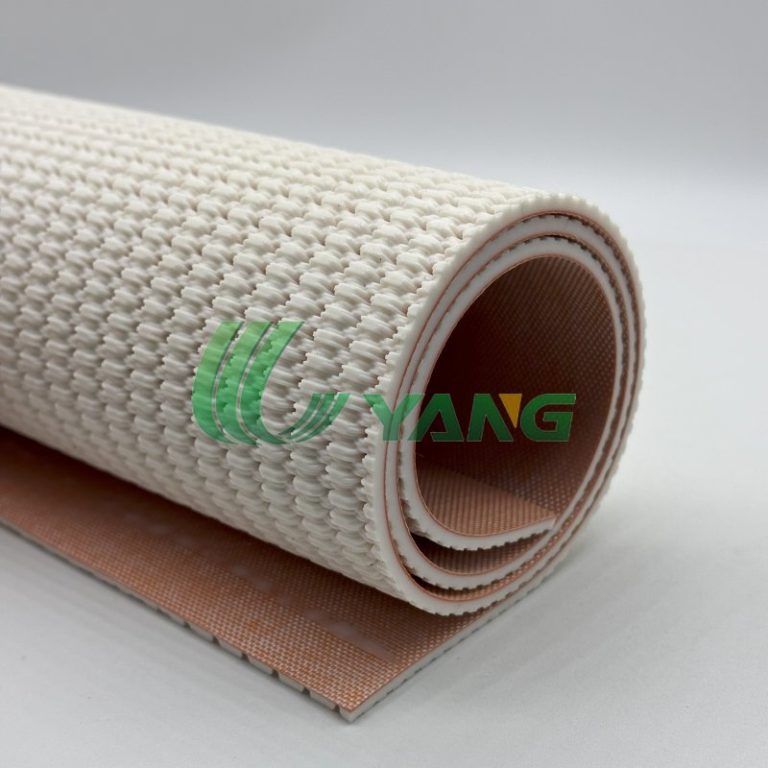

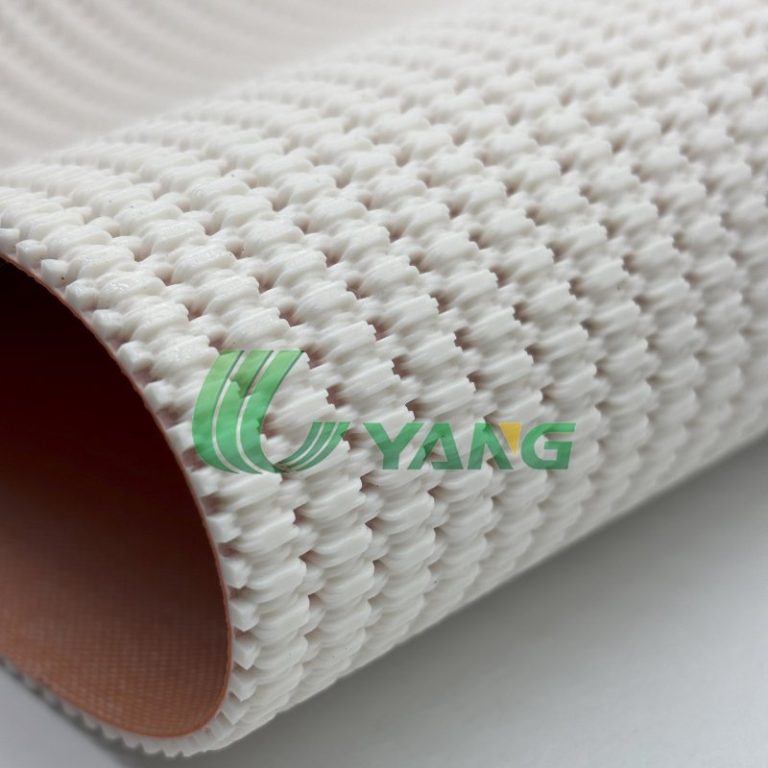

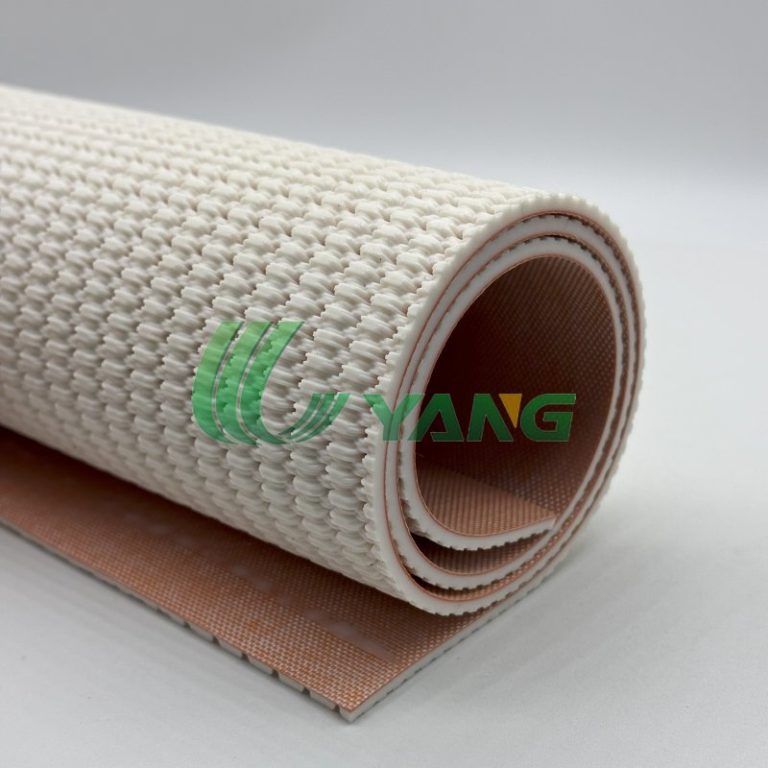

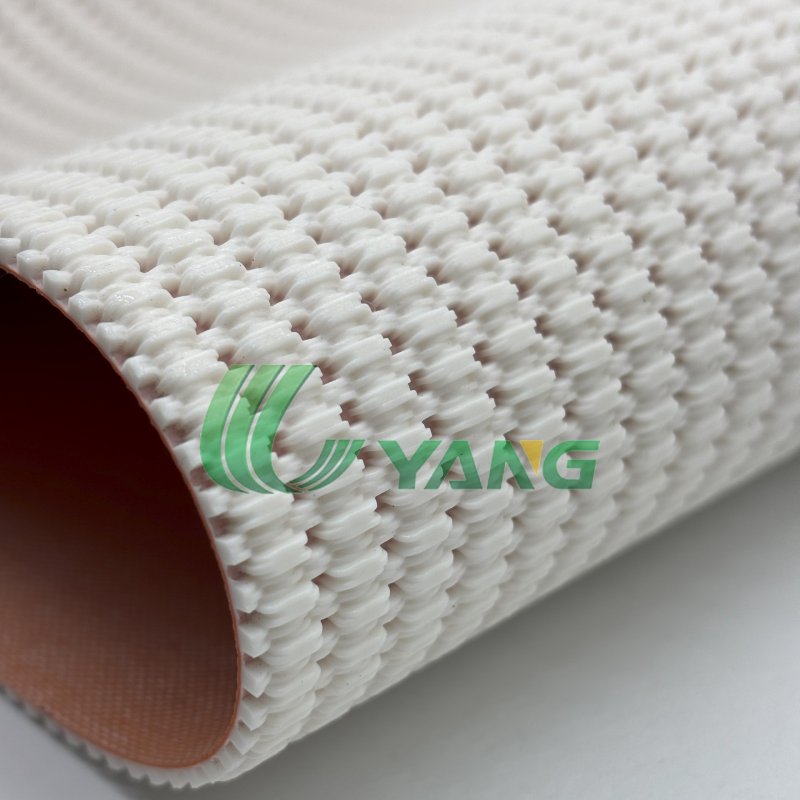

UYANG BELTING shallow-grass (浅草纹) silicone molds accurately transfer the belt’s anti-slip texture into hot-press or vulcanized splice areas, ensuring consistent grip, appearance and cleanability across the entire conveyor surface.

UYANG BELTING shallow-grass (浅草纹) silicone molds accurately transfer the belt’s anti-slip texture into hot-press or vulcanized splice areas, ensuring consistent grip, appearance and cleanability across the entire conveyor surface.

Key benefits

Texture continuity — reproduces the shallow-grass pattern at the splice so there’s no change in grip or product handling.

Durable & heat-resistant — made from high-temperature silicone suited for repeated hot-pressing and vulcanizing cycles.

Professional, hygienic finish — produces smooth, low-profile joints that match the rest of the belt visually and functionally, reducing product catch points and easing cleaning.

Typical specifications & options

Material: high-temperature silicone (food-grade options on request)

Pattern: standard shallow-grass pitch/depth (custom pattern matching available)

Sizes: standard sheets or custom cut to belt width and splice length

Thickness: engineered for optimal pattern transfer under recommended press settings

Compatibility: for PVC and PU conveyor belts with diamond/anti-slip surfaces.

How it’s used (quick steps)

Prepare belt ends—clean and trim to even edges.

Insert splice film (if used) and align the belt ends in the hot-press.

Position the shallow-grass silicone mold over the splice area with the patterned side facing the belt.

Apply heat and pressure per belt/splice press parameters.

Allow to cool; remove mold and inspect the pattern transfer.

Finish edges and test the joint under working load.

Applikationer

Factory splices and on-site repairs for diamond-top PVC/PU belts in food, packaging, logistics, and light industry.

Any production line where consistent anti-slip performance and uniform appearance across splices are required.

Why choose our shallow-grass silicone molds

Precision pattern transfer keeps product handling consistent and reduces rework. Durable, customizable molds help maintain hygienic surfaces and professional-looking splices—saving time and improving line reliability.

Pålidelige leveringsplaner og lagerstøtte.

Konkurrencedygtige priser for at maksimere den samlede værdi.

Diverse muligheder for at imødekomme alle markedssegmenter.

Fleksibel MOQ -support med alle typer varer;

Personaliseret logo -tilpasning på produkterne

Giv online teknisk support til alle produktforbrug og installationsprocesser

Hurtig første svar på al undersøgelse og spørgsmål

Giv kvalitetsbilleder, video for at forbedre salgsindtægterne

Effektiv produktion og skib inden for 15 dage på det hurtigste.

Generelt er det 10-15 dage, hvis højsæsonen, vil det være ca. 15-20 dages bunker, der modtager depositum

1. bekræftet specifikation: tykkelse, farve, lag, karakteristisk og industri;

2. Prøver Sending: Vi sender prøver til dig check.eller du sender os prøver, hvis tilpasset bælte.

3. Bekræft ordre: Signing af salgskontrakt efter prøver bekræftet.

4. depositum: 30% depositum før masseproduktion.

5. Produktion arrangeret: Vi behandler produktionen.

6. Resterende betaling: Efter inspektion, saldo før afsendelse.

7. Forsendelse: Vi sender varerne til destinationsporten.

8. Bekræft Bill of Loading {{url_placeholder_0}} faktura {{url_placeholder_1}} Liste {{url_placeholder_2}} af oprindelse;