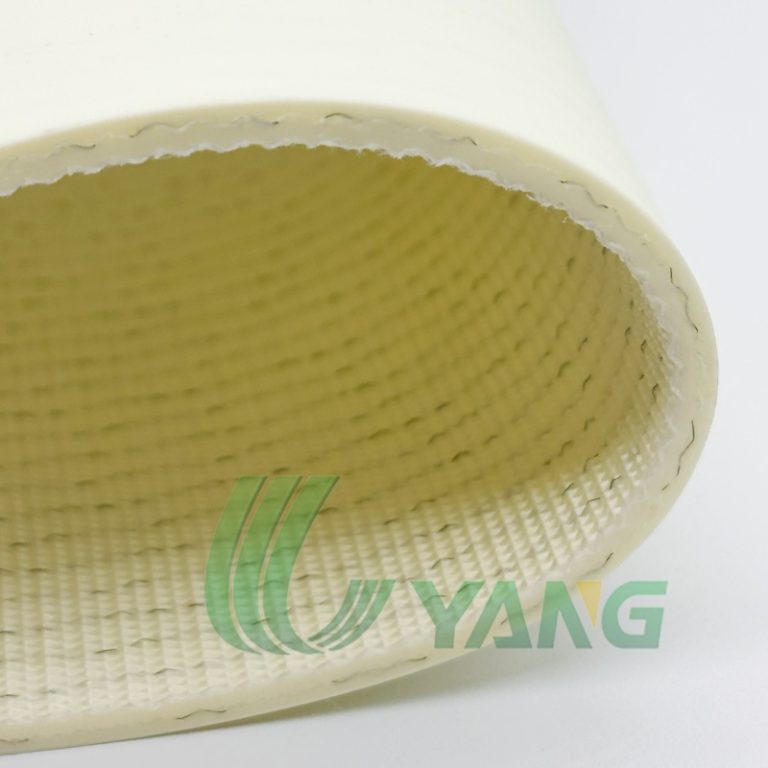

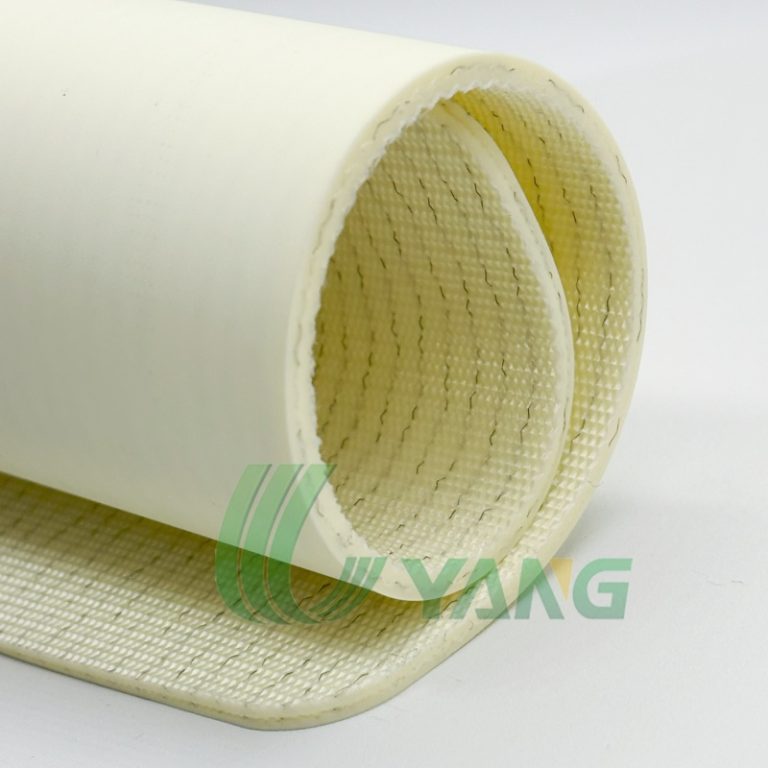

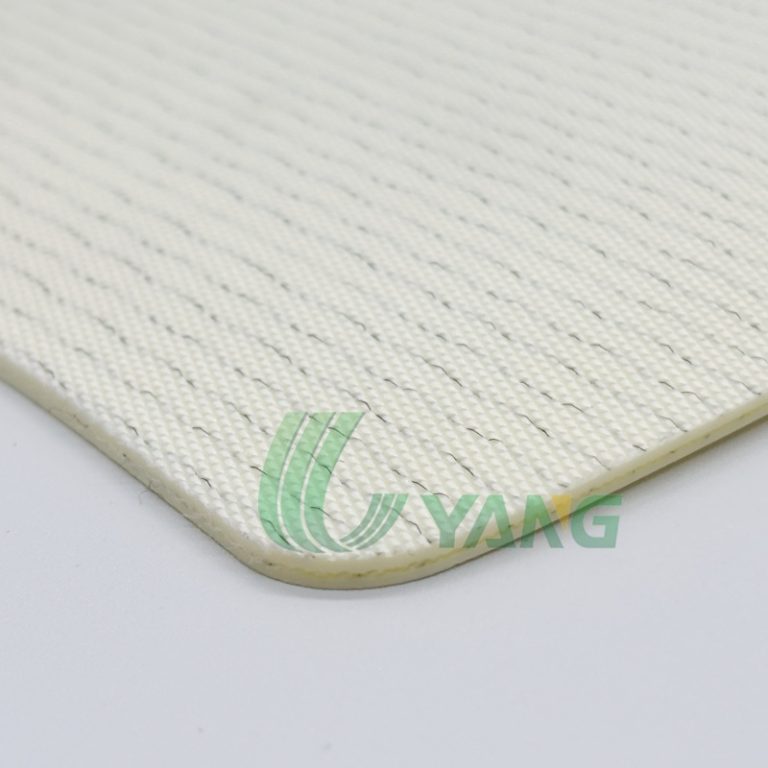

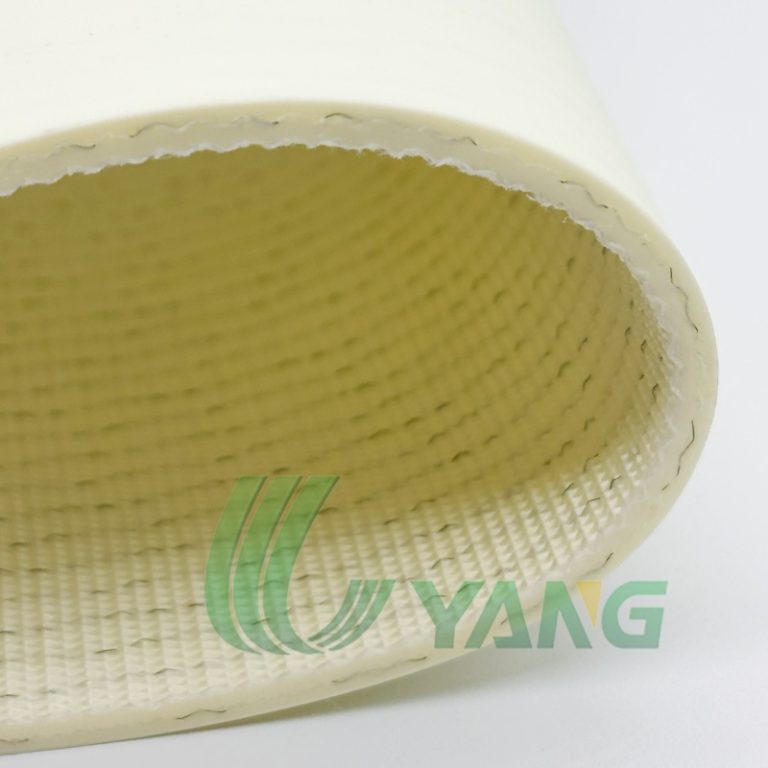

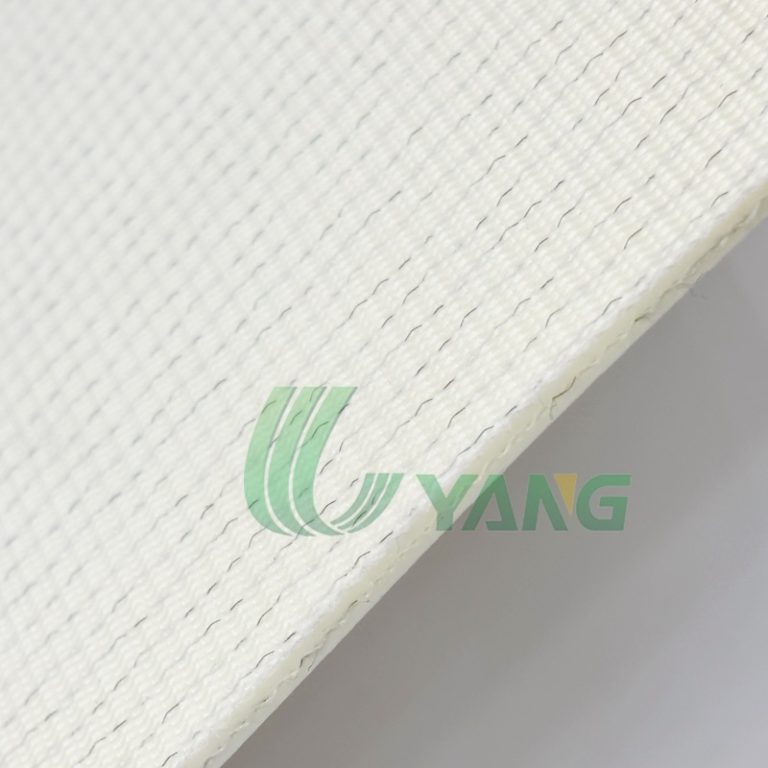

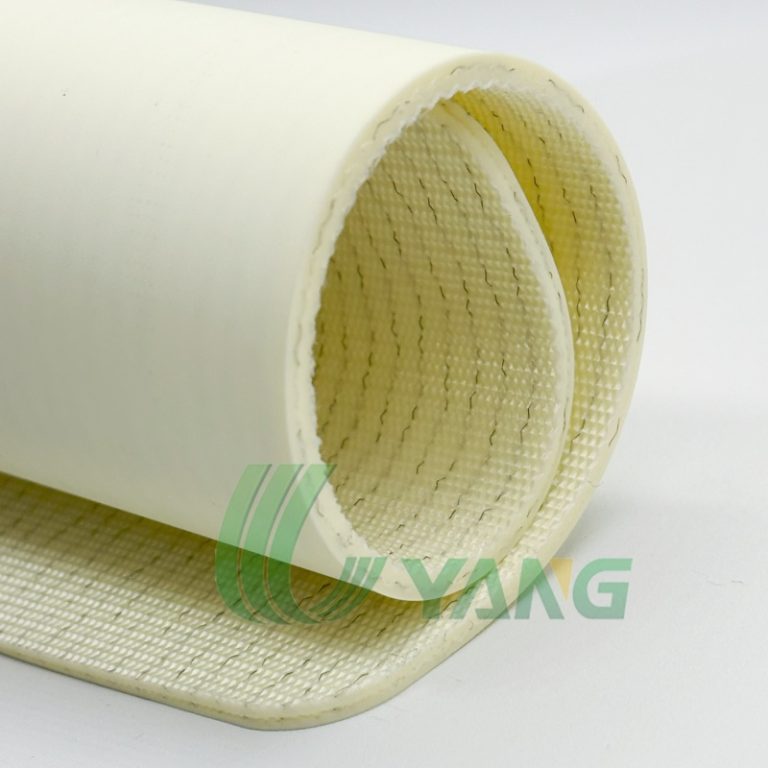

UYANG BELTING TPEE Belts – Premium tobacco-grade conveyor belts with exceptional strength, chemical resistance and hygienic properties.

UYANG BELTING TPEE Belts – Premium tobacco-grade conveyor belts with exceptional strength, chemical resistance and hygienic properties.

3× stronger than PVC (25-50 MPa tensile strength)

High impact resistance for heavy-duty, high-speed use

✔ Chemical & Moisture Resistance

Withstands oils, alcohols, and weak acids

Hydrolysis-proof, stable in >95% humidity

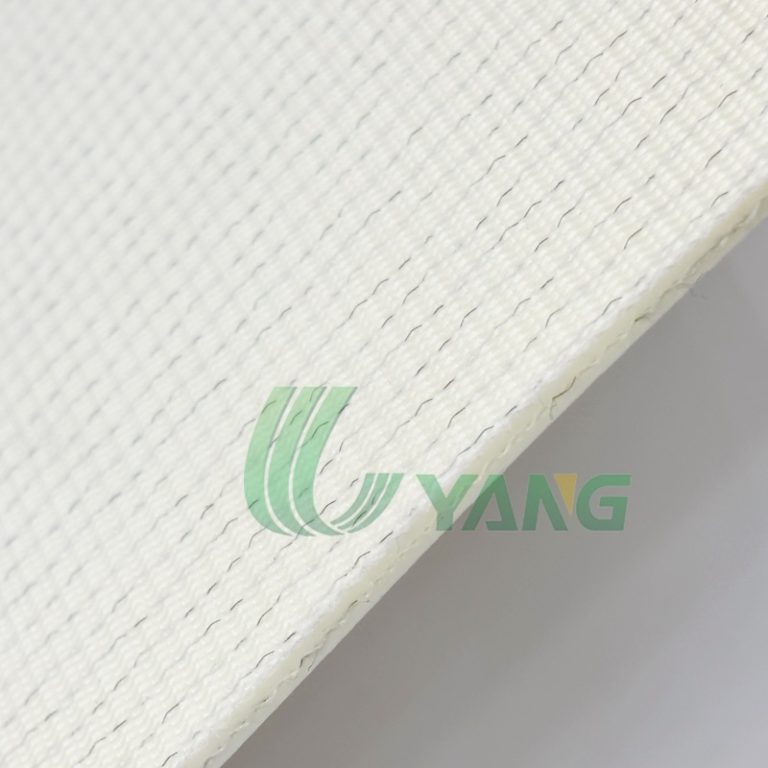

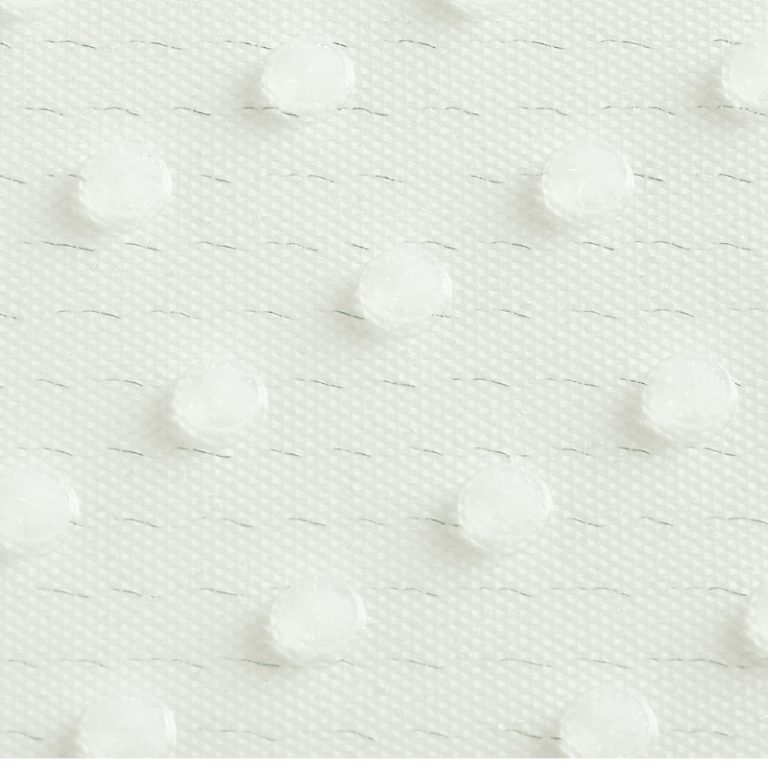

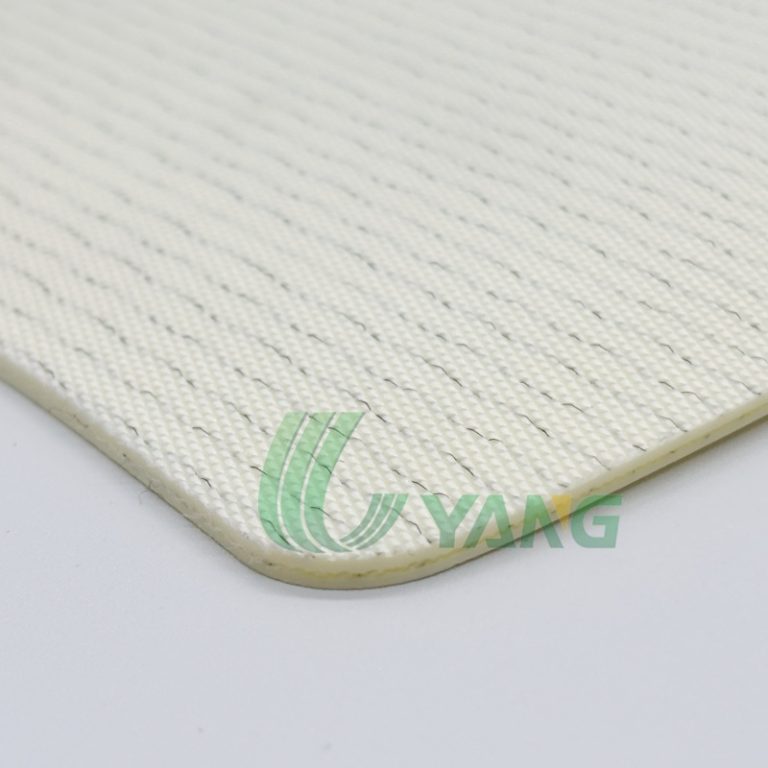

✔ Hygienic & Anti-Stick Surface

FDA-compliant, low-friction (0.3-0.5 coefficient)

Superior non-adhesion vs. PU belts

✔ Wide Temperature Range

Stable from -40°C to +120°C (short-term 150°C)

Ideal for: Cigarette production, cut tobacco transport, packaging lines

Engineered for reliability in harsh tobacco environments.

Designed specifically for tobacco applications, our TPEE conveyor belts provide unmatched reliability and efficiency in demanding processing environments.

Core Benefits:

✔ Optimized for Tobacco Handling

✔ Exceptional Longevity

✔ Enhanced Cleanliness & Safety

Technical Features:

Temperature range: -40°C to +120°C

High tensile strength: ≥25 MPa

Optional static control for sensitive operations

Engineered for peak performance in tobacco processing – where durability, hygiene, and efficiency matter most.

Technical Data:

| Aina | Plies | Rangi | pattern | Total Thickness

(mm) |

Cover thickness

(mm) |

Cover hardness

(mm) |

Weight

(kg/m2) |

Effective pull at 1% elongation

(N/mm) |

Breaking Strength

(N/mm) |

Min Dia

(mm) |

Counter Flexion |

| 25T22-84 | 2 | Blue | Smooth | 2.5 | 0.8 | 90 | 3.0 | 10 | 180 | 60 | 80 |

| 35T31-84/o | 3 | Blue | Matt | 3.5 | 0.5 | 90 | 4.2 | 15 | 270 | 100 | 120 |

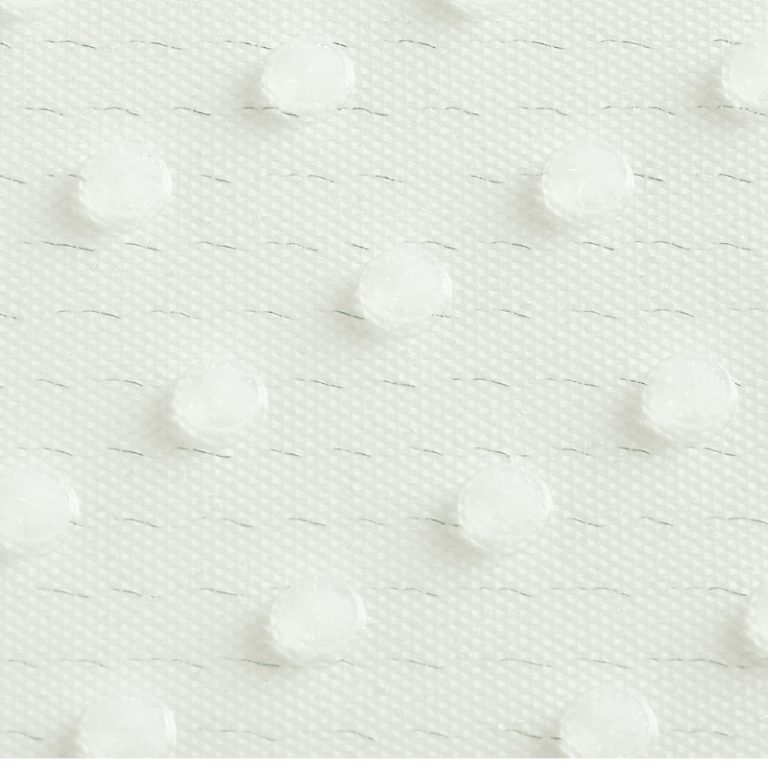

| 46T22-86/27 | 2 | Blue | Staggered stud | 4.6 | 2.6 | 90 | 3.9 | 14 | 160 | 80 | 140 |

Competitive Comparison

| Feature | TPEE | PU | PVC |

|---|---|---|---|

| Tensile Strength | ★★★★★ | ★★★☆ | ★★☆ |

| Temp Range | -40~120℃ | -10~80℃ | -10~80℃ |

| Hygiene Rating | FDA Certified | FDA Certified | Not Recommended |

Reliable delivery schedules and warehousing support.

Competitive pricing to maximize overall value.

Diverse options to cater to all market segments.

Flexible MOQ Support with all types of goods;

Personalized logo customization on the products

Provide online technical support for all product usage and installation processes

Quick first response to all inquiry and questions

Provide quality images, Video to enhance sales revenue

Efficient production and ship within 15 days at the fastest.

Generally it is 10-15 days, if peak season, it will be about 15-20 day safter receiving the deposit

1. Confirmed Specification: thickness,color, plies,characteristic, and industry;

2. Samples sending: we send samples for you check.or you send us samples if customized belt.

3. Confirm Order: Signing sales contract after samples confirmed.

4. Deposit: 30% deposit before mass production.

5. Production arranged : we will process the production.

6. Remaining payment: after inspection, balance before shipment.

7. Shipping: we will ship the goods to destination port.

8. Confirm bill of loading/commercial invoice/packing list/certificate of origin;