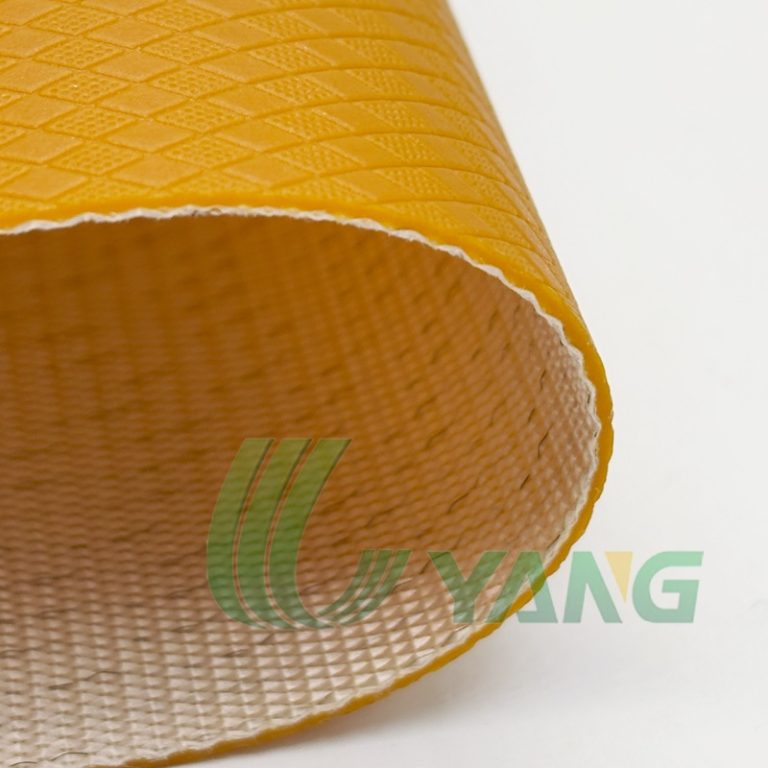

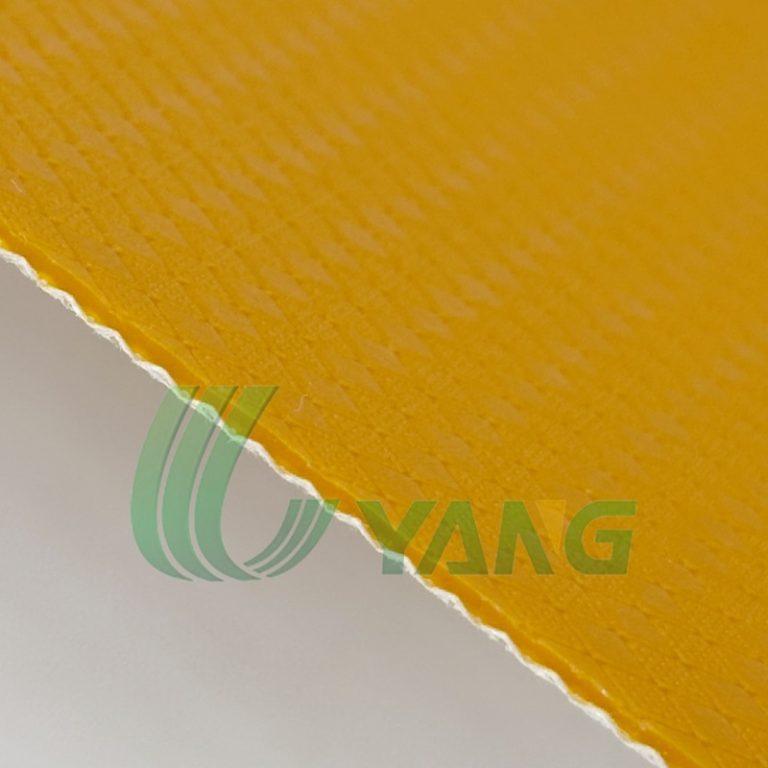

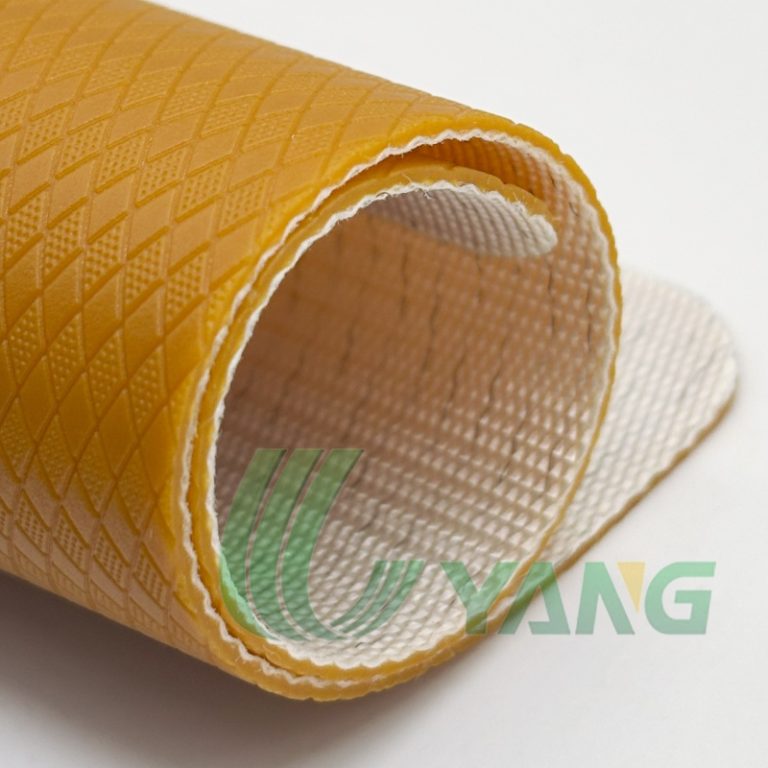

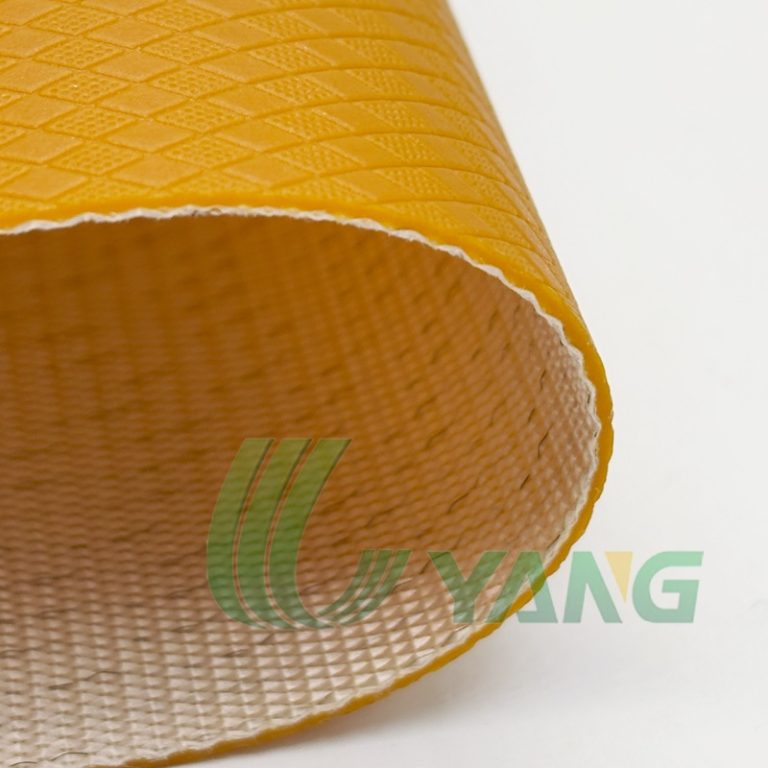

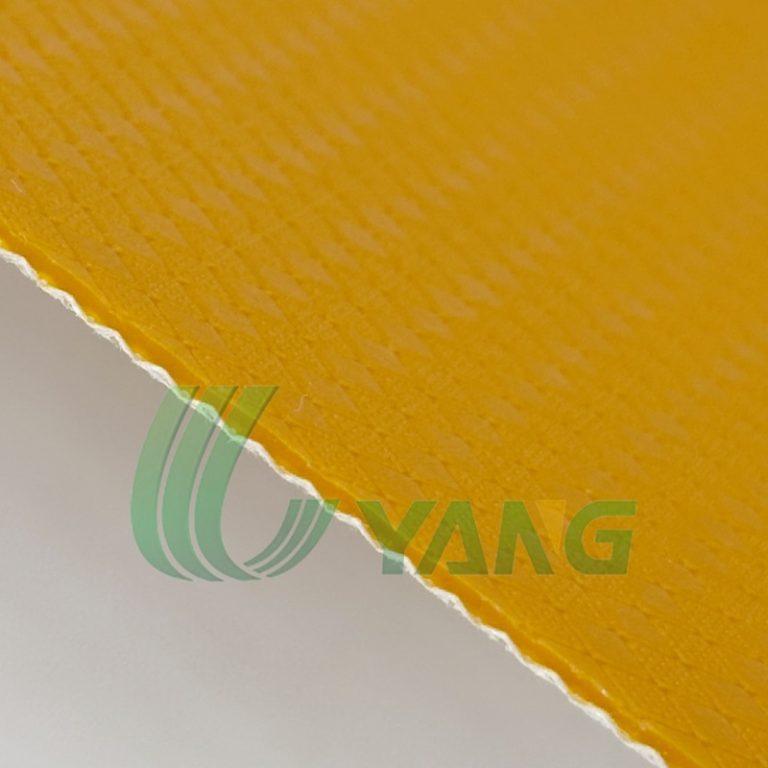

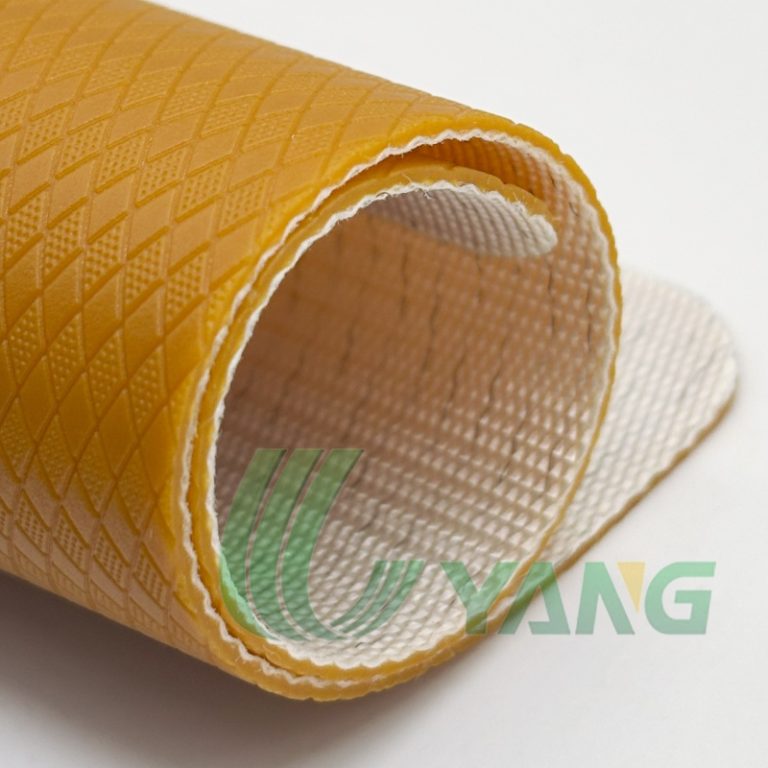

UYANG BELTING could provide the TPU conveyor belts for Chocolate Production with a special pattern design on the surface (Harkqui Pattern, Conves Rhombus pattern, or customized ). They are Top standards of hygiene, Curved belts ( Knife edge), and Superior grip and release properties. and patterns, colors, thickness, width, and length could be customized as required;

UYANG BELTING could provide the TPU conveyor belts for Chocolate Production with a special pattern design on the surface (Harkqui Pattern, Conves Rhombus pattern, or customized ). They are Top standards of hygiene, Curved belts ( Knife edge), and Superior grip and release properties. and patterns, colors, thickness, width, and length could be customized as required;

During chocolate production, the belts convey the production process at every processing step. so the belts have to have exceptional positioning accuracy and could be touched by the products directly; during conveying, there are lots of transfer points, very small end radii

We suggest that the belt should have one special pattern on the surface, top standards of hygiene, and a knife edge;

Top standards of hygiene;

Superior grip and release properties.

knife edges, curved belts.

PU conveyor belt has an essential impact on the efficiency, precision, and quality of the finished Chocolate production;

PU Conveyor Belt with a Convex Rhombus Pattern could guarantee the quality and safety of Chocolate during Chocolate Production.

| Top cover Material | TPU |

| Top cover Thickness | 0.7 mm |

| Features | Non-Stick |

| Rangi | Beige |

| Surface | Convex Rhombus pattern; |

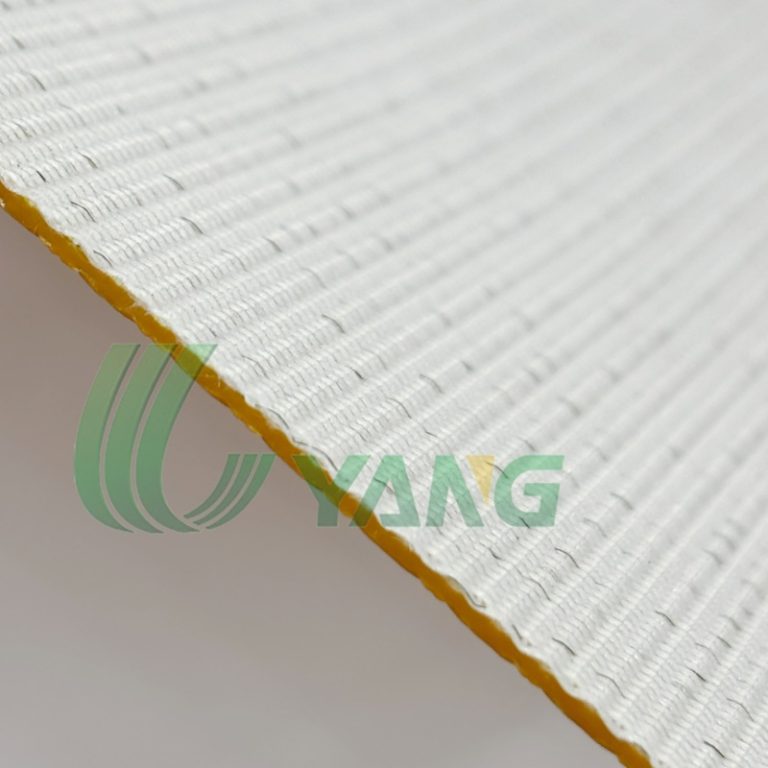

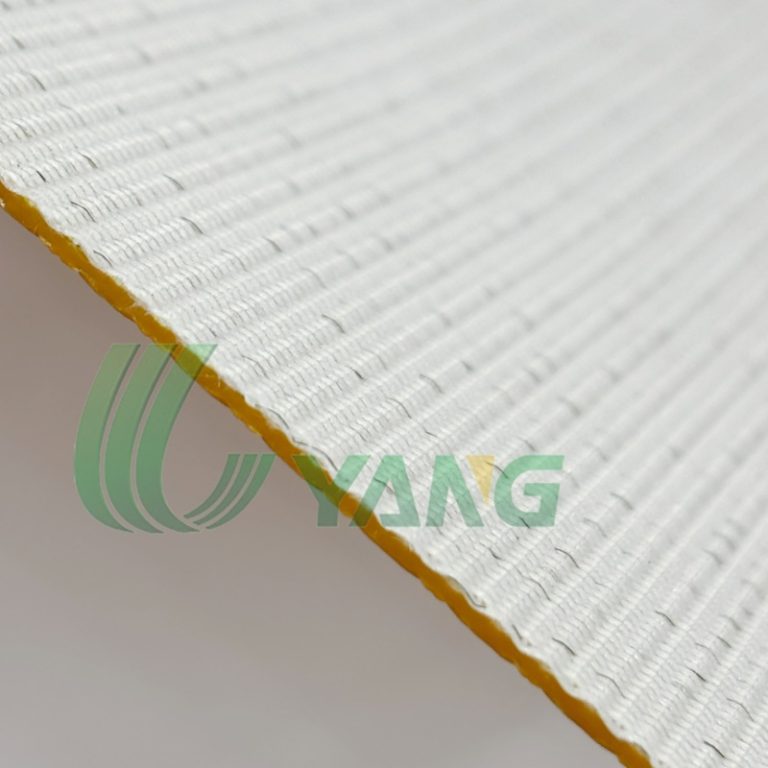

| Bottom Cover Material | Fabrics |

| Bottom Cover Thickness | 0.5mm |

| Surface | Fabrics |

| Rangi | —— |

Technical data:

| Total Thickness | 1.2 mm |

| Belt Weight: | 1.4 KG/M² |

| Fabric Plies | 1 ply |

| HARDNESS °ShoreA : | 85 ShoreA |

| 1% ELONGATION STRENGTH: | 4 N/MM |

| TEMPERATURE: | -15/+80 |

Min Roll Diameter

| Normal Flexion (mm) | 8 mm |

| Counter Flexion (mm) | 15 mm |

FDA, Oil, and fat resistance; Knife Edge belt;

Main industry segments:

Food Industry;

Applications:

Cholocate production;

Colors, Thickness, Plies, Patterns, Fabrics, width, and length, could be customized;

Reliable delivery schedules and warehousing support.

Competitive pricing to maximize overall value.

Diverse options to cater to all market segments.

Flexible MOQ Support with all types of goods;

Personalized logo customization on the products

Provide online technical support for all product usage and installation processes

Quick first response to all inquiry and questions

Provide quality images, Video to enhance sales revenue

Efficient production and ship within 15 days at the fastest.

Generally it is 10-15 days, if peak season, it will be about 15-20 day safter receiving the deposit

1. Confirmed Specification: thickness,color, plies,characteristic, and industry;

2. Samples sending: we send samples for you check.or you send us samples if customized belt.

3. Confirm Order: Signing sales contract after samples confirmed.

4. Deposit: 30% deposit before mass production.

5. Production arranged : we will process the production.

6. Remaining payment: after inspection, balance before shipment.

7. Shipping: we will ship the goods to destination port.

8. Confirm bill of loading/commercial invoice/packing list/certificate of origin;