Conveyor belts are essential in woodworking for efficiently transporting materials through cutting, sanding, and finishing processes. They enhance productivity by handling heavy loads and ensuring continuous operation, with flat belts being the most common choice. However, challenges like abrasion from sawdust, heat damage, and improper belt selection can lead to downtime. Choosing the right belt—wear-resistant (rubber/polyurethane), heat-resistant, and with proper load capacity—reduces maintenance costs and boosts efficiency. Uyang Belting offers specialized solutions, including durable rubber belts for sawmills and lightweight PVC belts for precision work, ensuring longevity and cost savings. Regular maintenance and investing in high-quality belts improve sustainability and operational reliability in woodworking.

What Role Do Conveyor Belts Play in Woodworking?

Why Are Conveyor Belts Crucial in Woodworking?

Conveyor belts are indispensable in woodworking operations, streamlining the transportation of raw materials and finished products. They ensure a seamless flow of wood pieces through various stages such as cutting, sanding, and finishing. The ability to handle heavy loads and operate continuously makes conveyor belts an essential component for improving productivity in woodworking facilities. Flat belt conveyors, which accounted for over 73.2% of the revenue share in 2024, are particularly popular due to their adaptability across multiple industries, including woodworking.

What Challenges Arise in Woodworking Conveyor Systems?

Despite their importance, woodworking conveyor systems face challenges such as wear and tear due to abrasive materials like sawdust and wood chips. Heat generation during processes like sanding can also degrade certain belt materials over time. Moreover, improper selection of conveyor belts can lead to frequent breakdowns, causing costly downtimes.

How Do You Choose the Right Conveyor Belt for Woodworking?

Is the Material Compatible with Woodworking Applications?

Selecting a material compatible with woodworking is vital for ensuring long-lasting performance.

Why Are Wear-Resistant Materials Necessary?

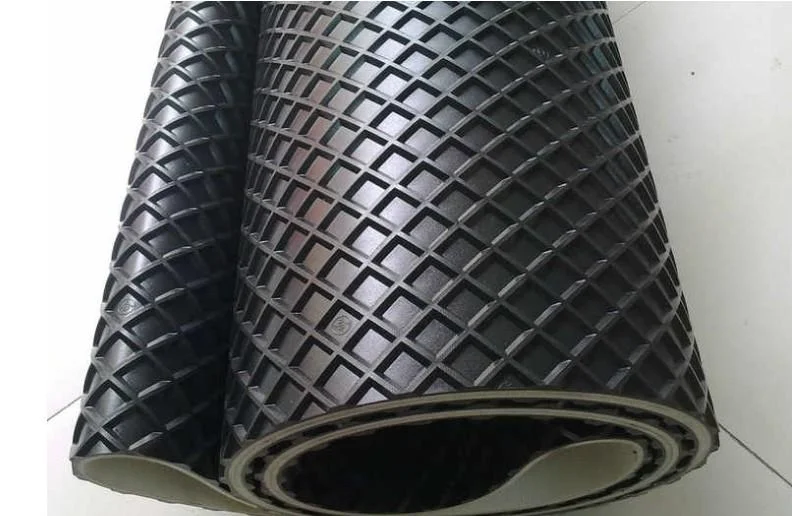

Woodworking often involves abrasive particles that can erode conveyor belts quickly. Using wear-resistant materials like rubber or polyurethane extends the belt’s lifespan by offering excellent resistance to abrasion and impacts. Rubber belts are particularly suitable for heavy-duty operations due to their strength and resistance to abrasion.

Are Heat-Resistant Belts Essential?

Certain woodworking processes generate heat that can damage standard belts. Heat-resistant options made from specialized polymers or treated fabrics prevent deformation or melting, ensuring uninterrupted operations.

How Important Are Load Capacity and Belt Strength?

The load capacity of a conveyor belt must align with the weight of wood materials being transported. Overloading a belt not designed for high weights can lead to premature failure. Medium-weight belts are commonly used in sectors like woodworking because they offer a balance between durability and flexibility. The medium-weight segment was valued at $2.5 billion in 2024, highlighting its widespread use.

Can Belt Speed Impact Operational Efficiency?

Yes, optimizing belt speed is critical for maintaining efficiency without compromising safety or product quality. Slower speeds may result in bottlenecks, while excessively high speeds could cause misalignment or damage to fragile wood pieces.

How Does Proper Belt Selection Reduce Maintenance Costs?

Can Durable Belt Choices Minimize Downtime?

Investing in high-quality conveyor belts reduces downtime caused by frequent replacements or repairs. Durable materials designed specifically for woodworking environments withstand the rigors of daily use, keeping your production line running smoothly.

How Do Quality Materials Lower Repair Costs?

Using premium-grade materials minimizes wear and tear, reducing the frequency of repairs needed over time. For example, polyurethane belts offer low friction and high durability, making them ideal for woodworking tasks involving repetitive motion.

Does Reliability Enhance Productivity?

Reliable conveyor belts ensure consistent performance, allowing you to focus on meeting production targets rather than troubleshooting equipment failures. This reliability not only boosts productivity but also enhances workplace safety by minimizing unexpected breakdowns.

For an all-encompassing solution tailored to your specific needs, explore Uyang Belting. With over 20 years of expertise and advanced production capabilities, they provide innovative conveyor belt solutions that enhance efficiency and reduce costs across industries, including woodworking.

Uyang Belting: A Trusted Solution for Woodworking Conveyor Belts

Uyang Belting provides durable conveyor belts for woodworking, including wear-resistant rubber belts for sawmills, heat-resistant options for sanding, and anti-slip designs for secure material handling.

Overview of Uyang Belting’s Product Range for Woodworking

Specialized Wear-Resistant Conveyor Belts

Conveyor belts in woodworking environments face constant exposure to abrasive materials such as sawdust, wood chips, and splinters. Selecting wear-resistant belts is essential to ensure durability and operational efficiency. Rubber belts are particularly suitable for heavy-duty operations due to their strength and resistance to abrasion. These belts withstand the rigors of transporting wood materials without succumbing to premature wear, making them an ideal choice for sawmills and other heavy-duty applications.

Heat-Resistant and Anti-Slip Belt Solutions

Certain woodworking processes, such as sanding or polishing, generate significant heat that can deteriorate standard belt materials. Heat-resistant belts, crafted from specialized polymers or treated fabrics, are designed to endure high temperatures without deformation. Additionally, anti-slip features ensure stability during the transportation of uneven or lightweight wood pieces, enhancing safety and precision in your operations.

Benefits of Choosing Uyang Belting Products

When you choose Uyang Belting, you are investing in over 20 years of expertise in conveyor belt solutions. Their advanced production capabilities ensure high-quality products tailored to meet the demands of the woodworking industry. With a focus on innovation and reliability, their conveyor belts provide enhanced durability, operational efficiency, and cost savings over time.

Recommendations for Cost-Efficient Conveyor Belt Selection

Uyang Belting offers specialized conveyor belt solutions for diverse woodworking needs, from heavy-duty sawmill operations requiring durable, medium-weight belts to precision machinery applications benefiting from lightweight PVC belts. Their medium-weight belts balance strength and flexibility for lumber processing, while PVC options deliver chemical resistance and adaptability for delicate tasks. Explore tailored solutions for optimal performance in industrial and precision woodworking environments.

Matching Specific Uyang Products to Common Woodworking Needs

Heavy-Duty Belts for Sawmills and Lumber Processing

Sawmills require conveyor belts capable of handling substantial loads and resisting damage from sharp-edged materials like logs or planks. Medium-weight belts are a popular choice due to their balance between flexibility and robustness. The medium-weight segment was valued at $2.5 billion in 2024, highlighting its widespread use. These belts offer excellent tensile strength while minimizing wear and tear during continuous operations.

Lightweight Options for Precision Machinery Applications

Precision woodworking machinery often involves the delicate handling of smaller components. Lightweight PVC conveyor belts are well-suited for these applications as they provide flexibility, chemical resistance, and easy maintenance. PVC Conveyor Belts available through Uyang Belting, they cater specifically to such needs with their lightweight construction and adaptability.

Tips for Prolonging the Lifespan of Your Uyang Conveyor Belts

- Regular Maintenance:Perform routine inspections to identify signs of wear or misalignment early.

- Proper Installation:Ensure the belt is correctly tensioned and aligned during installation to prevent unnecessary strain.

- Cleanliness:Keep the conveyor system free from debris like sawdust or resin buildup that could degrade the belt material.

- Load Management:Avoid exceeding the specified load capacity to prevent undue stress on the belt.

The Long-Term Value of Investing in High-Quality Conveyor Belts

Balancing Initial Costs with Operational Savings

While high-quality conveyor belts may come with a higher upfront cost, they significantly reduce long-term expenses by minimizing maintenance needs and downtime. Durable materials like polyurethane offer exceptional resistance against wear and friction, ensuring consistent performance over extended periods.

Ensuring Sustainable Practices in Your Woodworking Business

Investing in reliable conveyor systems aligns with sustainable business practices by reducing waste generated from frequent replacements. Moreover, advanced technologies incorporated into modern conveyor belts enhance energy efficiency, further supporting environmentally responsible operations.

FAQs

Q1. What type of conveyor belt is most suitable for abrasive woodworking environments?

A: Wear-resistant rubber belts are ideal due to their ability to handle abrasive materials like sawdust and wood chips effectively.

Q2. How can heat-resistant conveyor belts benefit woodworking processes?

A: They prevent deformation caused by high temperatures during processes like sanding or polishing, ensuring uninterrupted operations.

Q3. Are lightweight PVC belts reliable for precision woodworking tasks?

A: Yes, they offer excellent flexibility and chemical resistance while being easy to maintain, making them perfect for precision applications.