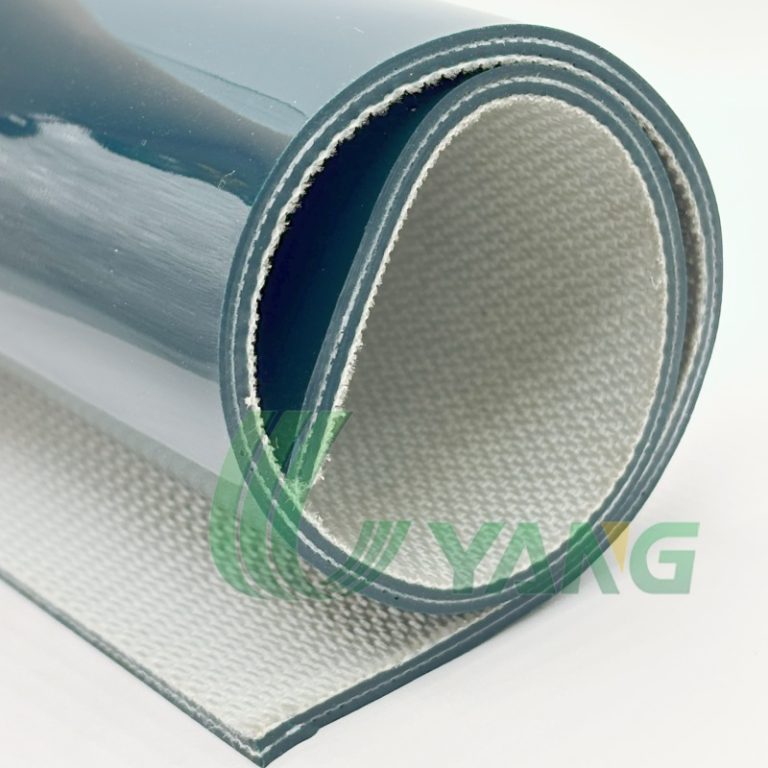

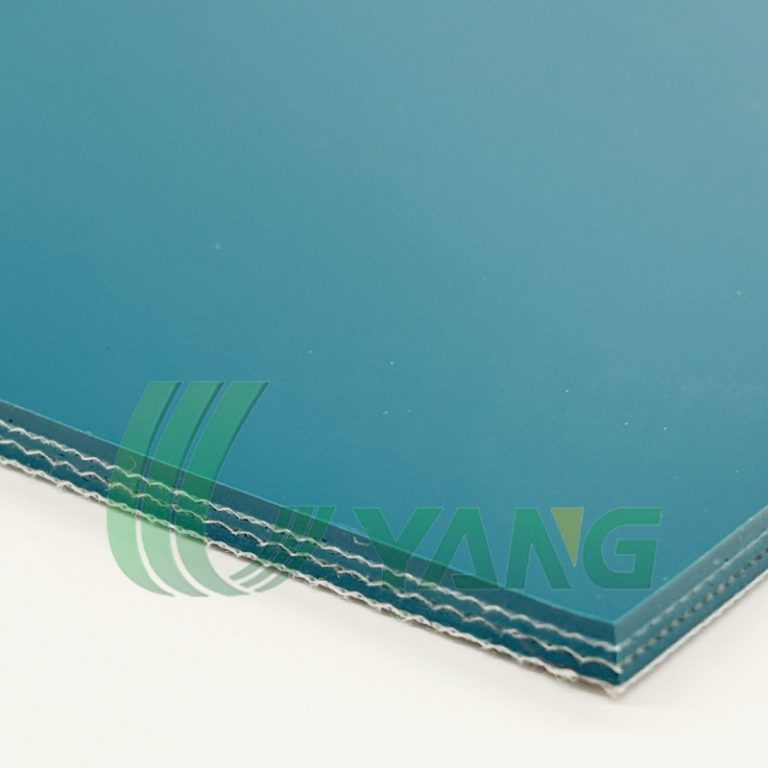

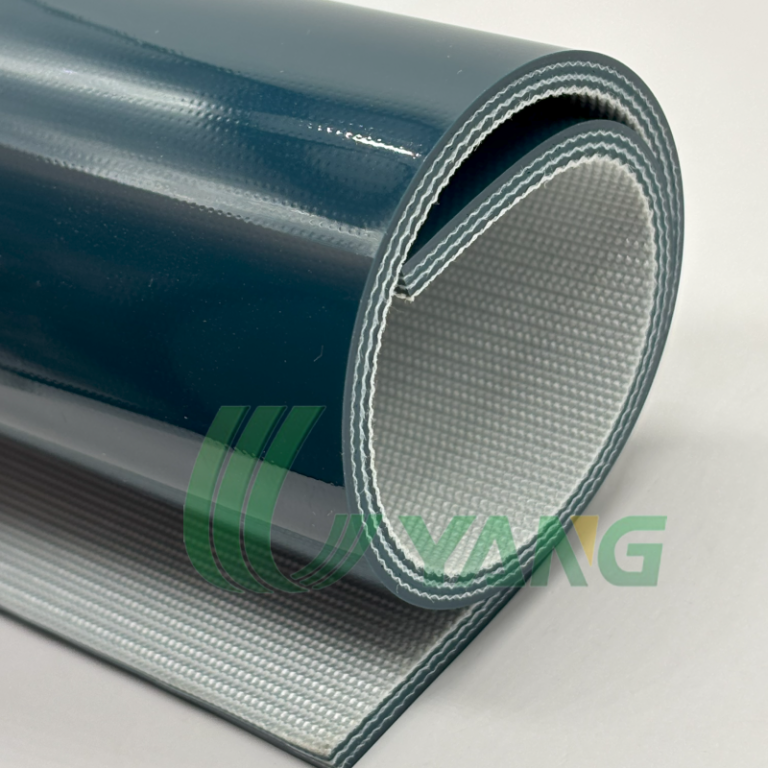

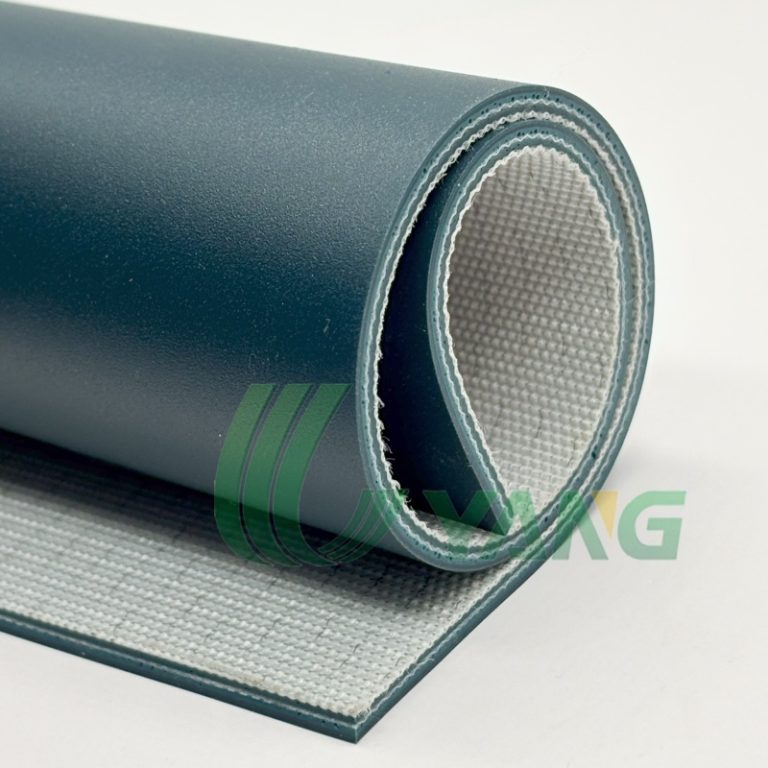

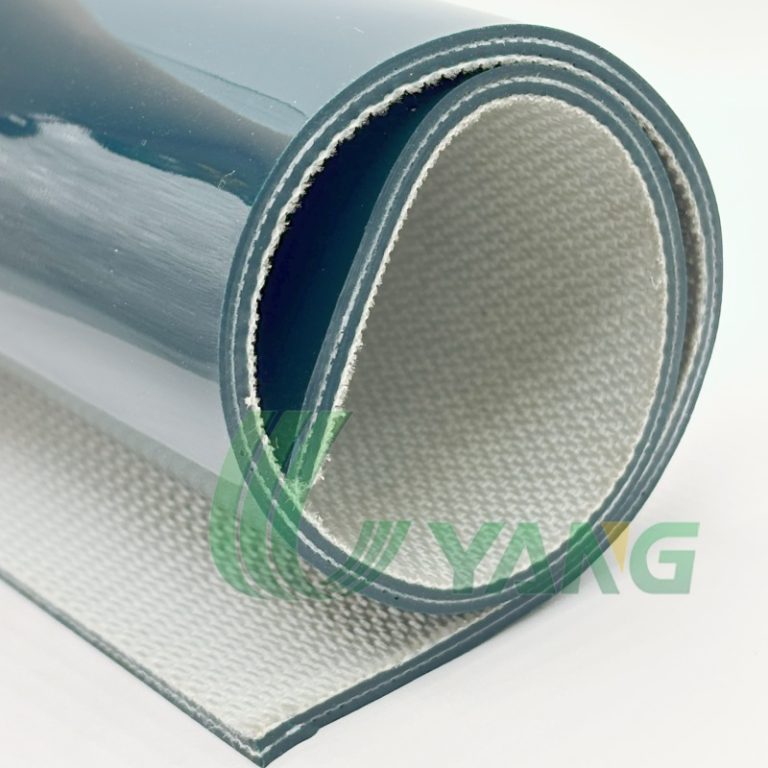

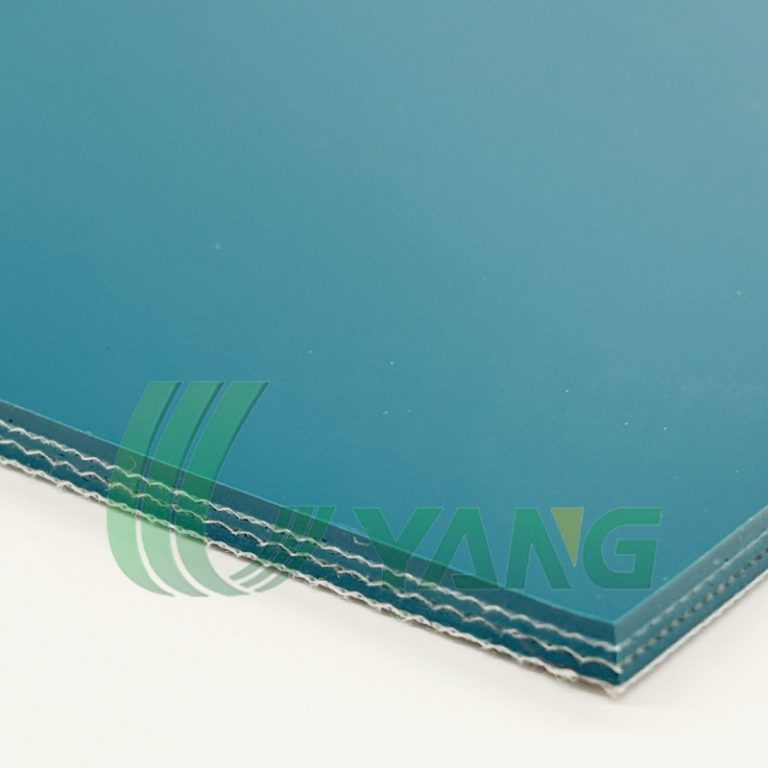

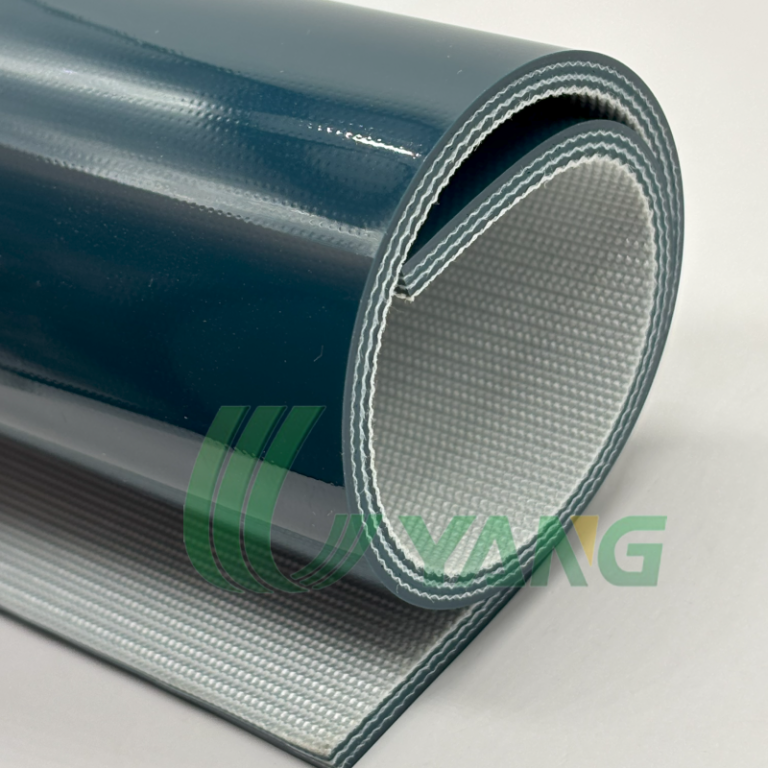

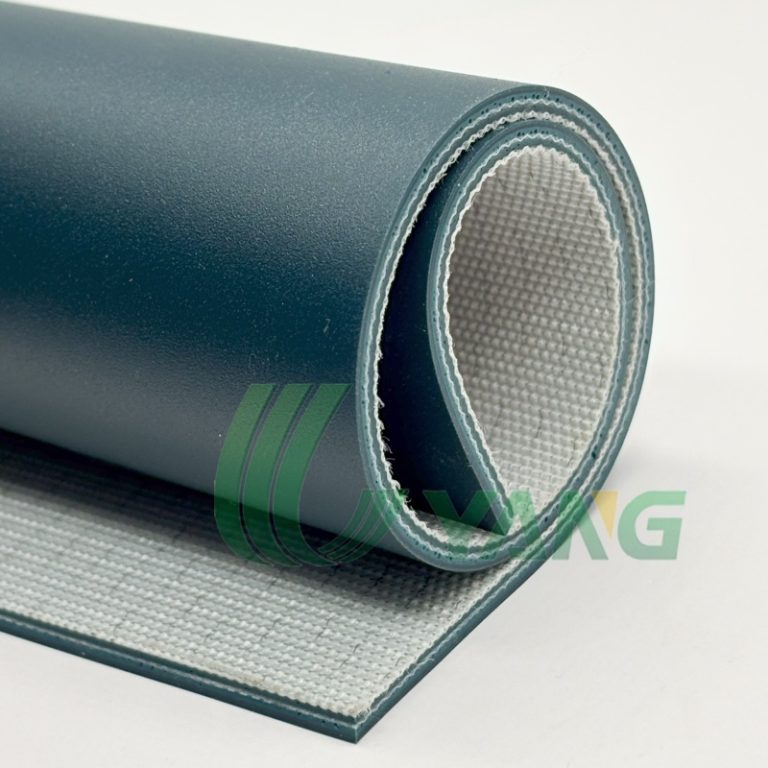

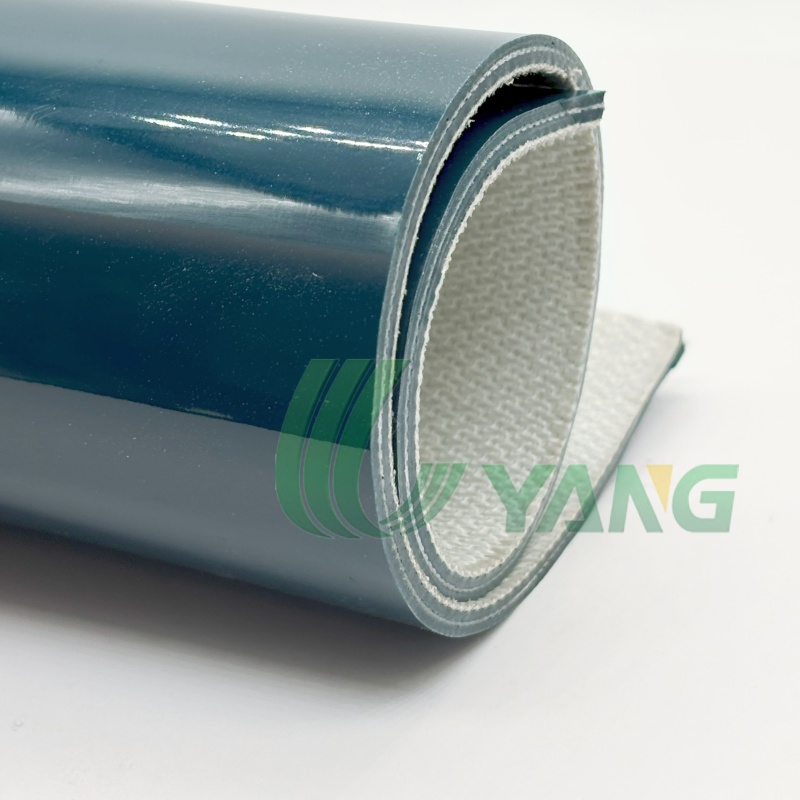

Petrol PVC conveyor belts are widely used in various light-duty conveying industries. The unique petrol shade provides better visual distinction from products and creates a clean, modern appearance in production environments.

Petrol PVC conveyor belts are widely used in various light-duty conveying industries. The unique petrol shade provides better visual distinction from products and creates a clean, modern appearance in production environments.

Advantages:

Clear product contrast and easy identification

Professional and aesthetic appearance

Same durability, flexibility, and reliability as standard green or blue PVC belts

Logistics & Parcel Handling

Used in sorting lines and parcel transfer systems, where the petrol color helps operators clearly distinguish belts from goods.

Electronics Industry

Suitable for handling small electronic components and light assemblies. The softer petrol tone reduces visual fatigue for operators working long hours.

Printing & Packaging

Commonly applied in paper, carton, and packaging transfer lines. The color ensures easy product contrast and a neat appearance.

Automated Warehousing Systems

Petrol belts are often used in automated storage and retrieval systems to transport boxes, trays, and parcels.

Woodworking & Furniture Industry

Ideal for conveying wooden boards, panels, and furniture components. The belt’s durable surface resists wear and maintains a professional look.

General Industrial Conveying

Selected by many factories for visual management and standardized production environments.

| Industry | Ansökan | Recommended Thickness / Model |

| Livsmedelsindustri | Bakery, fruit & vegetable processing, packaging | 1.5 – 3.0 mm, FDA/food-grade PVC |

| Logistics & Warehousing | Sorting lines, parcel conveyors, distribution hubs | 2.0 – 3.5 mm, anti-static PVC |

| Printing Industry | Paper conveying, carton handling, packaging lines | 1.5 – 2.5 mm, low-noise PVC |

| Ceramic Industry | Tile handling, polishing lines | 3.0 – 4.5 mm, wear-resistant PVC |

| Treadmill / Fitness | Running machines, fitness equipment | 1.6 – 2.2 mm, high-grip PVC |

| Woodworking / Furniture | Panel transfer, furniture assembly lines | 2.5 – 4.0 mm, abrasion-resistant |

| Electronics Industry | Component transfer, assembly lines | 1.5 – 2.5 mm, anti-static PVC |

| Tobacco Industry | Cigarette conveying, packaging | 2.0 – 3.0 mm, food-grade PVC |

| Automotive / Tire | Rubber parts transfer, tire handling | 3.5 – 5.0 mm, heavy-duty PVC |

| Gips styrelseindustri | Board forming and processing lines | 3.0 – 4.5 mm, taper-edge PVC |

Tillförlitliga leveransplaner och lagerstöd.

Konkurrenskraftig prissättning för att maximera det totala värdet.

Olika alternativ för att tillgodose alla marknadssegment.

Flexibel MOQ -stöd med alla typer av varor;

Personlig logotypanpassning på produkterna

Ge teknisk support online för alla produktanvändnings- och installationsprocesser

Snabbt första svar på all utredning och frågor

Ge kvalitetsbilder, video för att förbättra försäljningsintäkterna

Effektiv produktion och fartyg inom 15 dagar på det snabbaste.

Generellt sett är det 10-15 dagar, om högsäsongen kommer det att vara cirka 15-20 dagars säkerhet som får insättningen

1. Bekräftad specifikation: tjocklek, färg, skivor, karakteristiska och industri;

2. Prover Skickning: Vi skickar prover för dig check. Eller du skickar till oss prover om anpassat bälte.

3. Bekräfta beställning: Undertecknande försäljningsavtal efter prover bekräftade.

4. Insättning: 30% insättning före massproduktion.

5. Produktion ordnade: Vi kommer att bearbeta produktionen.

6. Återstående betalning: Efter inspektion, balans före leverans.

7. Frakt: Vi skickar varorna till destinationsporten.

8. Bekräfta Bill of Loading {{url_placeholder_0}} faktura {{url_placeholder_1}} List {{url_placeholder_2}} av ursprung;