UYANG BELTING offers a comprehensive range of sidewall conveyor belting solutions designed to enhance product throughput and minimize material loss.

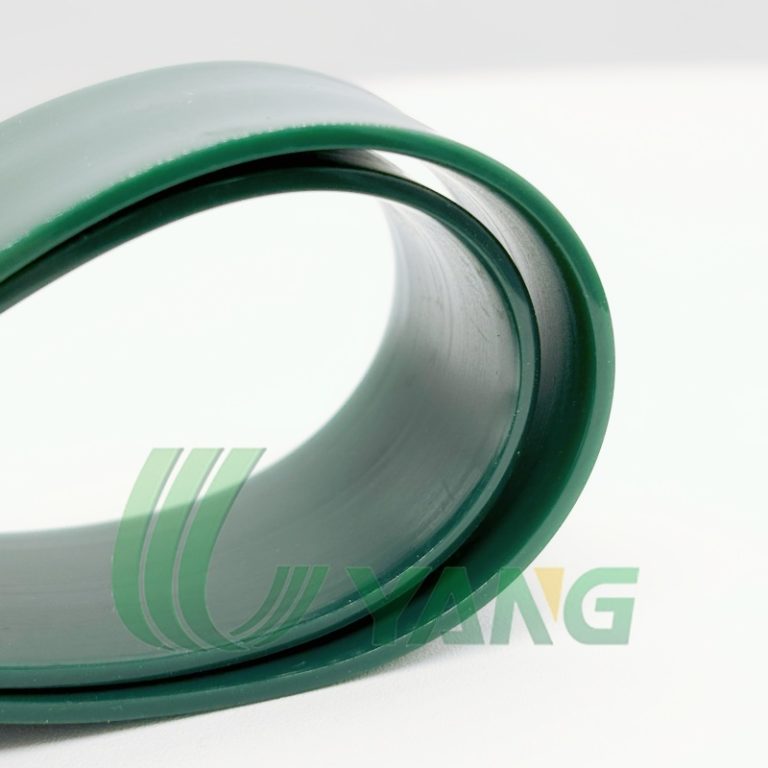

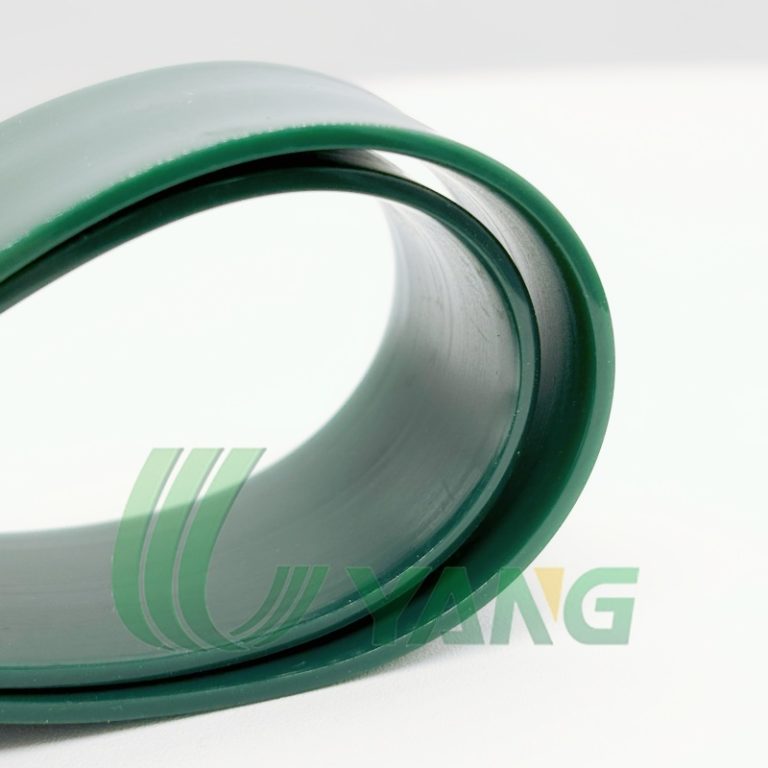

Corrugated sidewall conveyor belts serve as a protective barrier, preventing materials from spilling off the belt. They are ideal for conveying products on both inclines and declines.Designed with flexibility in mind, corrugated sidewalls are suitable for use with both small and large pulley diameters.Our sidewall conveyor belts are engineered to optimize product load capacity, enhancing the overall efficiency of your conveyor system and contributing to increased profitability.

UYANG BELTING offers a comprehensive range of sidewall conveyor belting solutions designed to enhance product throughput and minimize material loss.

Corrugated sidewall conveyor belts serve as a protective barrier, preventing materials from spilling off the belt. They are ideal for conveying products on both inclines and declines.Designed with flexibility in mind, corrugated sidewalls are suitable for use with both small and large pulley diameters.Our sidewall conveyor belts are engineered to optimize product load capacity, enhancing the overall efficiency of your conveyor system and contributing to increased profitability.

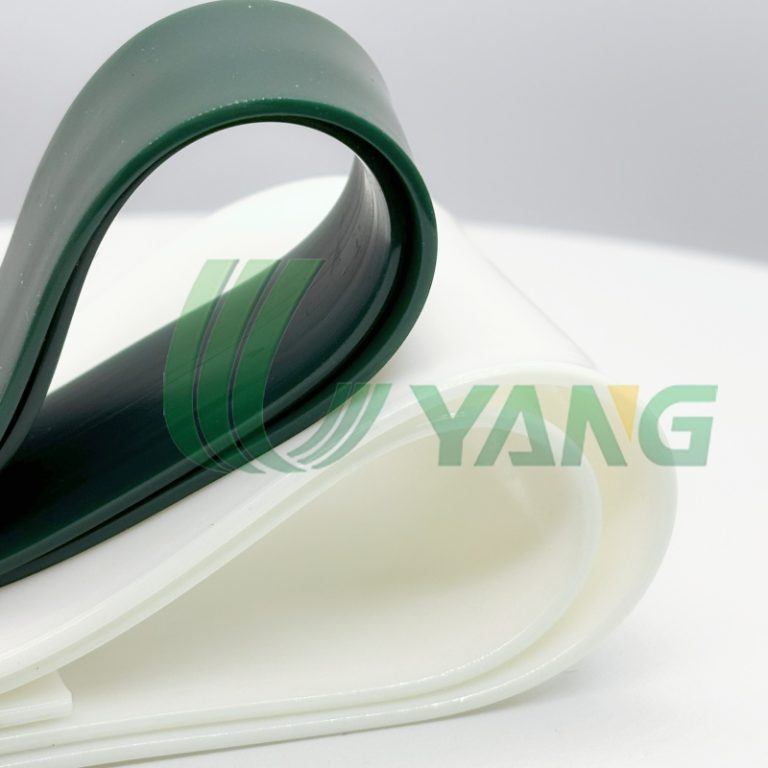

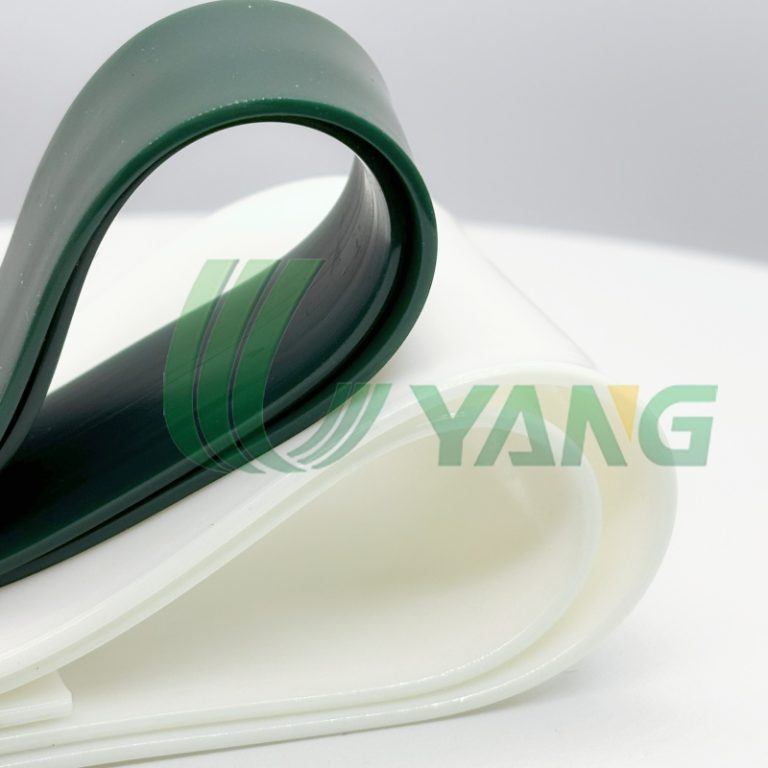

Compatible with all TPU and PVC belting materials:

The UYANG BELTING Sidewall material is specially engineered for optimal bonding and seamless integration with both TPU and PVC belts.

High-quality fitting made easy:

Corrugated Sidewalls can be effortlessly attached using hot air, High Frequency (HF) welding machines, or manual methods directly on-site.

Fitting of ends prepared:

Whether in your facility or at the installation site, splicing and joining both ends of Sidewall belts equipped with UYANG BELTING Sidewalls can be done swiftly and accurately.

Corrugated sidewall belts ensure stable conveying with enhanced product flow

The Corrugated sidewalls guarantee spill-free product movement. The corrugated design enables smooth belt articulation around pulley systems.

Perfect welding of the base: The belt base and corrugations utilize identical PVC/ TPU compounds. This creates seamless bonding throughout the sidewall belt structure, maintaining perfect adhesion whether paired with PVC or TPU top covers.

Superior sidewall characteristics: no additive or plasticizers and intrinsically and permanently flexible.

UYANG BELTING polyurethane sidewalls deliver: Exceptional tear resistance, outstanding protection against cuts, oils, fats, and rigorous cleaning processes, substantially extending your belt’s service life and operational durability.

| Technical Data of SIDEWALL | ||||||||||

| type | Material | färg | Yta | Tjocklek | Höjd

( mm) |

Corrugation Width

(mm) |

Hårdhet

(ShoreA) |

Min Pulley Dia(mm)

backflex |

Weight

( 3mm as thickness) (kg/M) |

Tempeature

(℃) |

| S20 | Pvc | Blue/green/white/

transparent |

Jämna | 3.0mm | 20mm | 40 mm | 85 | 90 mm | 0.08 kgs/M | -15/80 |

| S30 | Pvc | Blue/green/white/

transparent |

Jämna | 3.0mm | 30 mm | 40 mm | 85 | 120 mm | 0.1 kgs/M | -15/80 |

| S40 | Pvc | Blue/green/white/

transparent |

Jämna | 3.0mm | 40 mm | 40 mm | 85 | 160 mm | 0.165 kgs/M | -15/80 |

| S50 | Pvc | Blue/green/white/

transparent |

Jämna | 3.0mm | 50 mm | 40 mm | 85 | 180 mm | 0.11 kgs/M | -15/80 |

| S60 | Pvc | Blue/green/white/

transparent |

Jämna | 3.0mm | 60mm | 40 mm | 85 | 220 mm | 0.175 kgs/M | -15/80 |

| S70 | Pvc | Blue/green/white/

transparent |

Jämna | 3.0mm | 70 mm | 40 mm | 85 | 220 mm | 0.2 kgs/M | -15/80 |

| S80 | Pvc | Blue/green/white/

transparent |

Jämna | 3.0mm | 80mm | 40 mm | 85 | 300 mm | 0.21 kgs/M | -15/80 |

| S90 | Pvc | Blue/green/white/

transparent |

Jämna | 3.0mm | 90 mm | 40 mm | 85 | 300 mm | 0.3 kgs/M | -15/80 |

| S100 | Pvc | Blue/green/white/

transparent |

Jämna | 3.0mm | 100mm | 40 mm | 85 | 360 mm | 0.35 kgs/M | -15/80 |

| S20 | Tpu | Blue/green/white/

transparent |

Jämna | 2.0 mm | 20mm | 40 mm | 85 | 90 mm | 0.05 kgs/M | -15/80 |

| S30 | Tpu | Blue/green/white/

transparent |

Jämna | 2.0 mm | 30 mm | 40 mm | 85 | 120 mm | 0.075 kgs/M | -15/80 |

| S40 | Tpu | Blue/green/white/

transparent |

Jämna | 2.0 mm | 40 mm | 40 mm | 85 | 160 mm | 0.115 kgs/M | -15/80 |

| S50 | Tpu | Blue/green/white/

transparent |

Jämna | 2.0 mm | 50 mm | 40 mm | 85 | 180 mm | 0.14 kgs/M | -15/80 |

| S60 | Tpu | Blue/green/white/

transparent |

Jämna | 2.0 mm | 60mm | 40 mm | 85 | 220 mm | 0.18 kgs/M | -15/80 |

| S70 | Tpu | Blue/green/white/

transparent |

Jämna | 2.0 mm | 70 mm | 40 mm | 85 | 220 mm | 0.175 kgs/M | -15/80 |

| S80 | Tpu | Blue/green/white/

transparent |

Jämna | 2.0 mm | 80mm | 40 mm | 85 | 300 mm | 0.195 kgs/M | -15/80 |

| S90 | Tpu | Blue/green/white/

transparent |

Jämna | 2.0 mm | 90 mm | 40 mm | 85 | 300 mm | 0.28 kgs/M | -15/80 |

| S100 | Tpu | Blue/green/white/

transparent |

Jämna | 2.0 mm | 100mm | 40 mm | 85 | 360 mm | 0.3 kgs/M | -15/80 |

Tillförlitliga leveransplaner och lagerstöd.

Konkurrenskraftig prissättning för att maximera det totala värdet.

Olika alternativ för att tillgodose alla marknadssegment.

Flexibel MOQ -stöd med alla typer av varor;

Personlig logotypanpassning på produkterna

Ge teknisk support online för alla produktanvändnings- och installationsprocesser

Snabbt första svar på all utredning och frågor

Ge kvalitetsbilder, video för att förbättra försäljningsintäkterna

Effektiv produktion och fartyg inom 15 dagar på det snabbaste.

Generellt sett är det 10-15 dagar, om högsäsongen kommer det att vara cirka 15-20 dagars säkerhet som får insättningen

1. Bekräftad specifikation: tjocklek, färg, skivor, karakteristiska och industri;

2. Prover Skickning: Vi skickar prover för dig check. Eller du skickar till oss prover om anpassat bälte.

3. Bekräfta beställning: Undertecknande försäljningsavtal efter prover bekräftade.

4. Insättning: 30% insättning före massproduktion.

5. Produktion ordnade: Vi kommer att bearbeta produktionen.

6. Återstående betalning: Efter inspektion, balans före leverans.

7. Frakt: Vi skickar varorna till destinationsporten.

8. Bekräfta Bill of Loading {{url_placeholder_0}} faktura {{url_placeholder_1}} List {{url_placeholder_2}} av ursprung;