Conveyor belts are super important for keeping factories and production lines running smoothly. They move stuff from one spot to another, whether it’s food, medicine, or other goods. For years, Volta conveyor belts have been a top pick because they’re trusty and clean. But if you’re looking for a cheaper option that works just as well, positive drive belts from Uyang Belting are a great choice. These belts are super clean, tough, and easy to care for, making them a solid swap for Volta belts.

This guide will walk you through picking the right positive drive belt for your needs. We’ll also explain why they’re an awesome stand-in for Volta belts and how they can help your business. Honestly, it’s pretty cool how these belts can save money and still get the job done.

What Are Positive Drive Belts?

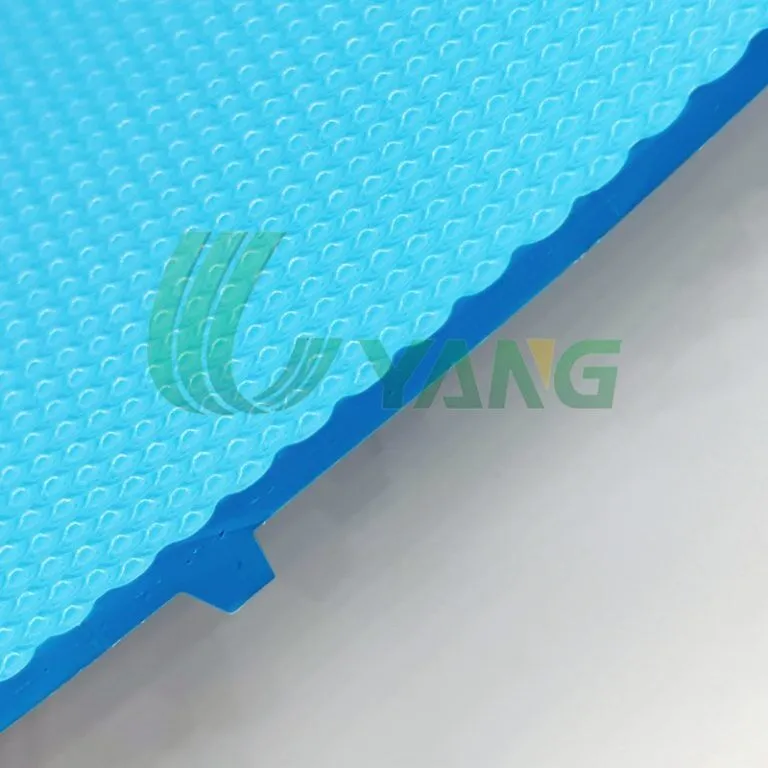

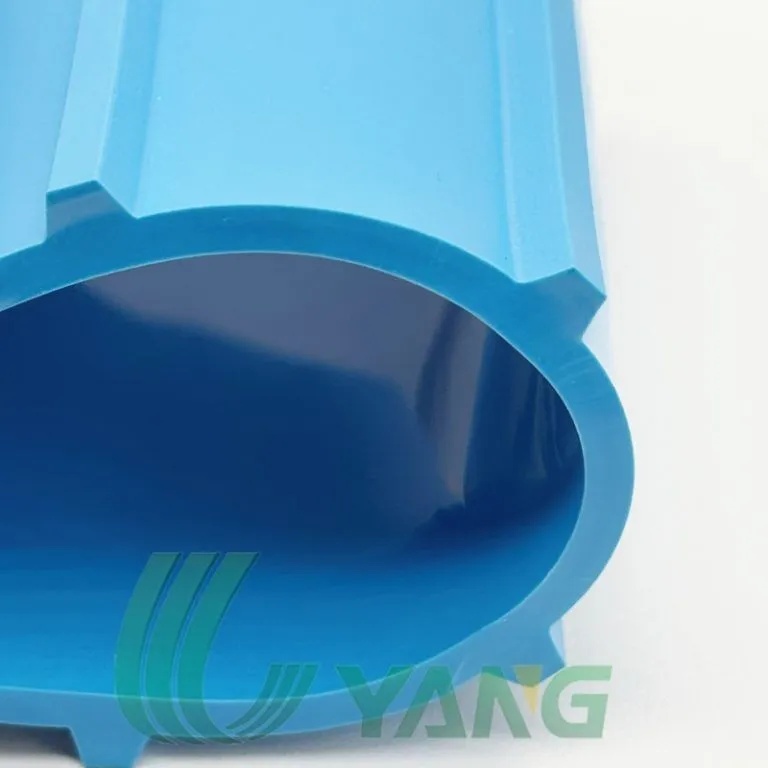

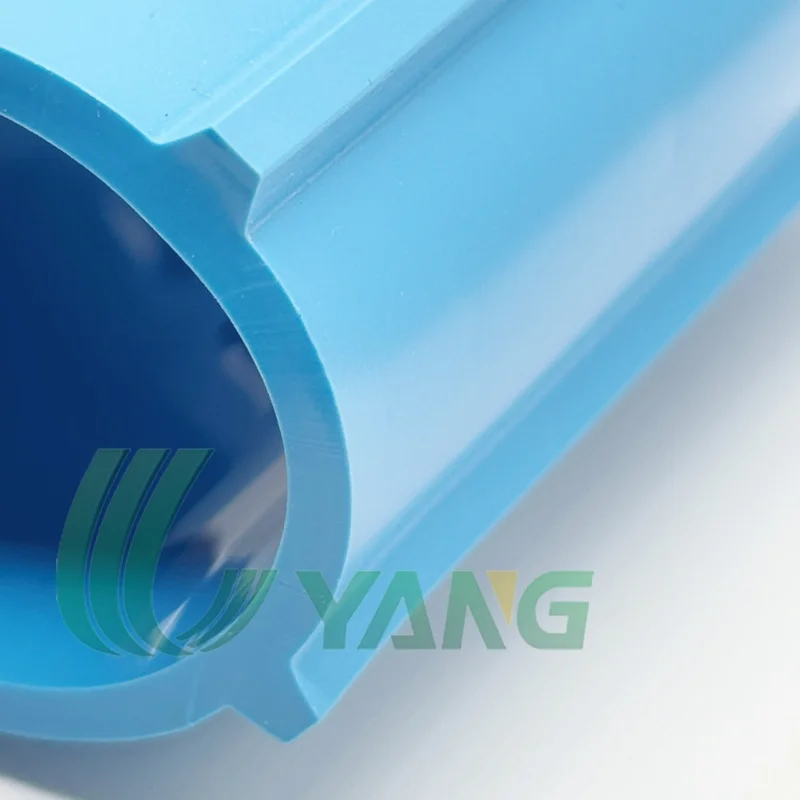

En positive drive belt is a type of conveyor belt made from one solid material, usually thermoplastic polyurethane (TPU). Unlike regular belts with layers, these have a smooth, solid build that brings lots of perks.

The big deal with positive drive belts is how clean they are. Their smooth, non-porous surface stops germs from growing. That’s perfect for places like food factories or medicine plants where hygiene is a must. These belts also stand up to oils, chemicals, and hot temperatures, so they work for all kinds of jobs.

Uyang Belting’s positive drive belts are extra special because you can customize them. Need a grippy texture or a certain thickness? They’ve got you covered. Here’s what makes their belts stand out:

- Easy to Clean: The smooth surface makes cleaning quick and simple.

- Super Tough: They handle wear and tear, even in rough conditions, so you don’t need to replace them often.

- No Seams: No fabric layers means no spots for germs to hide.

For example, a bakery in Ohio switched to Uyang Belting’s positive drive belts and cut cleaning time by 20%, saving $2,000 a year in labor costs.

Why Consider Volta Conveyor Belts?

Volta conveyor belts are popular for a reason. They’re tough and great for places needing top-notch cleanliness, like food or drug production. But businesses looking to save cash might want a cheaper option. That’s where Uyang Belting’s positive drive belts come in—they match Volta’s performance but cost less.

Volta belts work great, but they can be pricey upfront. Their layered design, while strong, might need more upkeep or fixes over time. Uyang Belting’s positive drive belts, though, give you the same cleanliness and toughness at a lower price. Plus, they’re easier to clean, which cuts down on long-term costs.

A meat processing plant in Texas tried Uyang Belting’s belts instead of Volta’s. They saved 15% on costs and spent less time on maintenance, keeping their line running smoothly.

Comparing Positive Drive Belts with Volta Conveyor Belts

Let’s look at how Uyang Belting’s positive drive belts stack up against Volta conveyor belts in three big areas: performance, cost, and how well they fit different jobs.

Performance

Uyang Belting’s positive drive belts perform as good as, or even better than, Volta belts. Both are awesome for industries needing super clean conditions. But positive drive belts have a big edge when it comes to cleaning.

Their seamless design means no cracks or seams for dirt or germs to hide in. Volta belts, with their layers, can trap stuff in tiny gaps, making cleaning trickier. Positive drive belts are a breeze to wipe down, cutting contamination risks.

Plus, Uyang Belting’s belts handle oils, chemicals, and extreme heat like champs. They’re great for food processing, medicine making, or packaging. A dairy plant in Wisconsin used Uyang Belting’s belts and reported zero contamination issues after a year, compared to occasional problems with layered belts.

Cost Analysis

Positive drive belts save you money over time. They might cost a bit more upfront than regular layered belts, but you save on upkeep, downtime, and replacements.

Uyang Belting designs their positive drive belts to be budget-friendly without skimping on quality. A packaging company in California switched to these belts and cut maintenance costs by $3,000 a year. They also needed fewer repairs, saving even more.

Application Suitability

Positive drive belts are perfect for industries needing super clean setups. Think food processing, medicine, or packaging. They shine in places like meat plants, seafood lines, or dairy production where cleanliness is everything.

For businesses watching their budget, Uyang Belting’s positive drive belts are a great swap for Volta belts. They perform just as well but cost less. Plus, you can customize them for specific jobs, making them super versatile.

A pharmaceutical lab in New Jersey used Uyang Belting’s belts in their cleanroom. The belts met strict hygiene rules and saved 10% on costs compared to Volta belts.

How to Select the Right Positive Drive Belt

Picking the perfect positive drive belt is key to making your work run smoothly. Here’s what to think about when choosing Uyang Belting’s positive drive belts as a Volta alternative:

1. Assess Your Specific Needs

Figure out what your operation needs. Do you need a belt for heavy stuff or one that’s cleaned a lot? Positive drive belts are flexible, but some jobs need special features like grippy textures or extra thickness for strength.

2. Consider Sizing and Customization

Once you know your needs, pick the right size and features. Uyang Belting offers different thicknesses, textures, and colors. You can get smooth or grippy surfaces, add coatings for oil resistance, or choose custom sizes to fit your line perfectly.

3. Choose a Reliable Supplier

Quality matters, especially for industries with strict cleanliness rules. Uyang Belting makes top-quality positive drive belts that meet global standards. They also offer great support, like tech help to keep your system running smooth.

Real-World Applications

Lots of industries have switched to Uyang Belting’s positive drive belts and seen big wins:

- Matbearbetning: These belts are awesome for raw meat, dairy, or seafood. They’re easy to clean and stop germs. A poultry plant in Arkansas cut cleaning time by 30% with Uyang Belting’s belts, saving $4,000 yearly.

- Pharmaceuticals: They meet cleanroom hygiene needs, perfect for drug production. A lab in Pennsylvania used them and passed every hygiene check with zero issues.

- Baking and Confectionery: Their oil resistance and easy cleaning make them great for dough or baked goods. A cookie factory in Oregon saved $2,500 a year on maintenance with Uyang Belting’s belts.

Maintenance Tips for Positive Drive Belts

Regular Cleaning Keeps Them Fresh

Clean your positive drive belt daily to keep it germ-free. Use mild soap and water, then dry it well.

Store Properly

Keep belts in a dry, cool place when not in use. Avoid sun or damp spots to prevent damage.

Why Choose Uyang Belting’s Positive Drive Belts?

Uyang Belting’s positive drive belts are a fantastic alternative to Volta belts. They’re clean, tough, and easy to maintain, all at a lower price. They meet strict hygiene rules and work great for food, medicine, or packaging jobs. Plus, their custom options let you get exactly what you need.

Switching to Uyang Belting’s positive drive belts can make your work faster, cleaner, and cheaper. It’s honestly amazing how much these belts can do for your business while keeping your budget happy.

FAQs

Q1. What industries benefit most from using positive drive belts?

A: Positive drive belts are particularly beneficial in industries that require high hygiene standards, including food processing, pharmaceuticals, meat and poultry processing, and dairy production.

Q2. How do positive drive belts compare to traditional multi-layer belts like Volta?

A: Positive drive belts offer seamless, non-porous surfaces that are easier to clean and maintain compared to traditional multi-layer belts, which may have more complex cleaning requirements and a higher risk of bacterial growth.

Q3. Are positive drive belts more expensive than other conveyor belts?

A: While positive drive belts may have a higher initial cost, they offer long-term savings due to reduced maintenance, lower downtime, and longer lifespan, making them a more cost-effective choice in the long run.