Food factories, from tiny bakeries to huge meat plants, all focus on keeping things clean while running smoothly. One key piece of equipment that’s often ignored is the conveyor belt. Tailored flat homogeneous belts, sometimes called easy-to-clean belts, are changing how food factories work. They offer great cleanliness, toughness, and custom options. This article looks at how these belts improve work speed and how Uyang Belting, a top conveyor belt maker, provides solutions for all kinds of food factories.

Advantages of Tailored Flat Homogeneous Belts

Hygiene & Cleanability

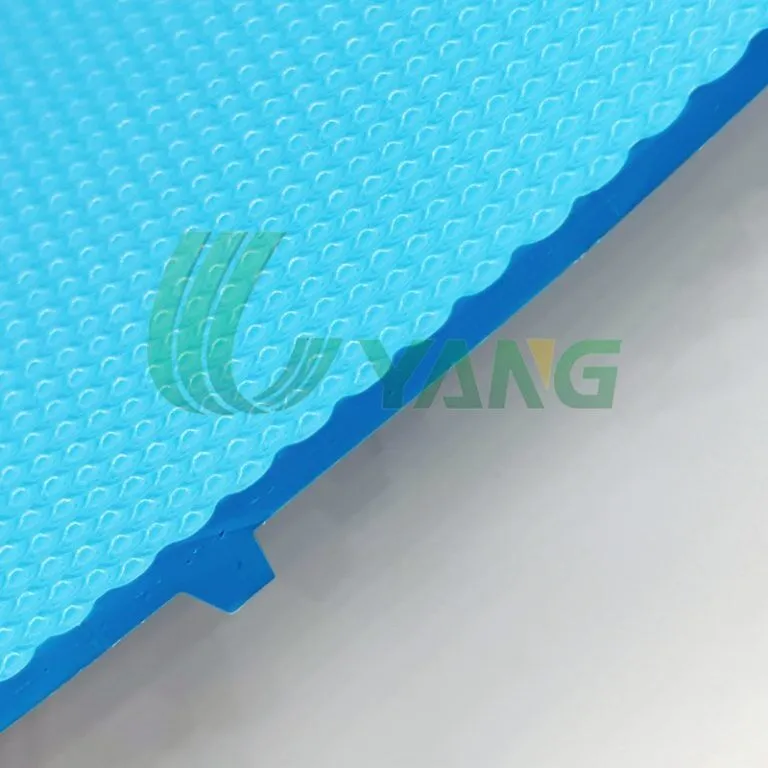

Unlike older belts made of layered fabric and plastic, flat homogeneous belts are one solid piece, usually made from TPU (Thermoplastic Polyurethane). This single-piece design has no seams or layers where germs can hide. It also doesn’t soak up liquids during processing. The smooth or slightly textured surface makes cleaning quick with hot water, steam, or FDA-approved cleaners. This cuts down on cleaning time and keeps the factory running longer.

Uyang Belting’s flat homogeneous belts meet FDA, EU 10/2011, and HACCP standards, so they’re safe for food contact.

Durability & Maintenance Efficiency

Flat homogeneous belts stand up well to oil, water, chemicals, and wear. With proper setup and care, they stay strong in wet or dry conditions. They don’t warp or fray at the edges over time. Uyang Belting’s belts have heat-welded joints that keep the belt even and strong. This makes swapping belts faster and prevents slipping or misalignment, saving money on repairs and labor.

Operational Efficiency & Scalability

Every food factory is different. A one-size-fits-all belt won’t work. Tailored flat homogeneous belts let you pick the thickness, surface texture, tension system, and drive type to match your needs. For example:

- Small factories, like cheese packagers, might need thin belts (2–3mm) for light products and tight turns.

- Big factories, like seafood processors, do better with thicker belts (3–5mm) that handle heavy loads and constant cleaning.

Uyang Belting offers custom sizes, textures, and colors—often blue to spot dirt easily.

Application Scenarios in Matbearbetning

Bakery & Dairy Lines

Flat homogeneous belts are great for moving dough, cheese, butter, or yogurt. Their non-stick and non-absorbent surfaces mean less product waste. They’re easy to clean and keep materials moving smoothly through cooling, cutting, and packing steps. For instance, a bakery can use these belts to move sticky dough without it getting stuck.

Meat, Poultry & Seafood Processing

These areas have high germ risks. Belts here face knife cuts, blood, oil, and quick cooling. Uyang Belting’s flat homogeneous belts have anti-cut and water-resistant coatings. Sealed edges stop liquids from sneaking in and growing bacteria, keeping the line safe and clean.

Prepared and Frozen Foods

Flat homogeneous belts work well in IQF (Individually Quick Frozen) systems and freezer tunnel conveyors. They stay tough in cold temperatures and don’t crack, which cuts downtime and product loss. For example, a frozen pizza line can rely on these belts to move products without breaking down.

Customization Options for Different Factory Scales

Every food factory has its own needs based on what it makes, its space, and its workflow. Uyang Belting offers tailored flat homogeneous belt solutions with:

- Material Choices: High-quality TPU with extras like germ-fighting, oil-resistant, or water-resistant additives.

- Thickness Options: From 1.5mm for light bakery work to 5mm for heavy meat lines.

- Surface Types: Smooth, diamond-patterned, or bumpy textures for different grip and cleanliness needs.

- Color Choices: Blue for spotting dirt, white for dairy, or custom colors if needed.

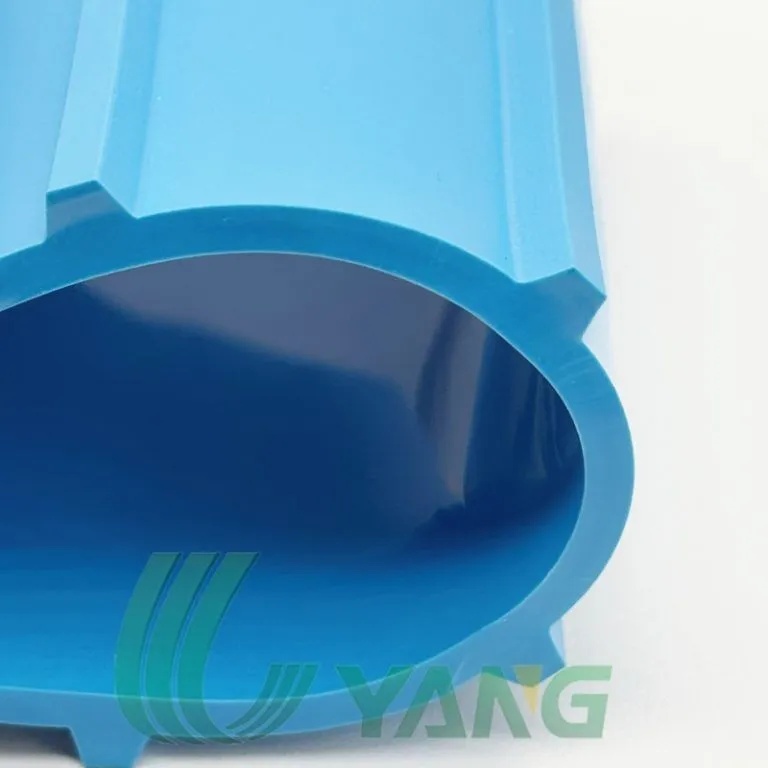

- Edge and Add-Ons: Sealed edges, cleats, perforations, or sidewalls for special tasks.

These options make factories cleaner and faster, no matter their size.

Installation & Maintenance Best Practices

Seamless Installation

Seamless joints keep things clean and steady. Uyang Belting suggests professional hot-melt welding for flat homogeneous belts. This keeps the belt’s width and strength even, unlike metal fasteners or glue, which can trap germs.

Sanitary Cleaning Protocols

- Daily: Wash with gentle, food-safe soap.

- Weekly: Use steam or chlorine-based cleaners for deep cleaning.

- Månatlig: Check for cuts, edge wear, or joint stress.

Optimized Accessories

To get the best results, Uyang Belting recommends using flat homogeneous belts with:

- Food-safe rollers and guides.

- Quick-release tension systems.

- CIP (Clean-in-Place) spray bars.

These extras cut cleaning time and keep the system running longer.

Total Cost of Ownership & ROI

Flat homogeneous belts might cost more upfront than standard PU or PVC belts, but they save money over time. Here’s how they compare:

| Metrisk | Traditional PU/PVC | Flat Homogeneous Belt |

| Cleaning Time | High | Low |

| Downtime | Frequent | Minimal |

| Replacement Cycle | 6–12 months | 24+ months |

| Risk of Germs | Medium | Low |

| ROI | Lower | Higher |

Uyang Belting’s clients in seafood and poultry have seen 30% less downtime and over 40% fewer labor hours for cleaning after switching to flat homogeneous belts.

Extra Tips for Maximizing Belt Performance

- Check Belt Tension: Make sure the belt isn’t too tight or loose. Proper tension prevents wear and keeps the belt running smoothly.

- Train Workers: Teach your team how to clean and inspect belts properly. This avoids damage from wrong handling, like using harsh chemicals.

- Monitor Wear Spots: Look for wear on high-contact areas, like where products load. Early fixes can prevent bigger issues.

- Use Food-Safe Lubricants: If the belt needs oiling, use only food-grade lubricants to keep things safe for food contact.

- Schedule Downtime Smartly: Plan cleaning during slow shifts to avoid disrupting production. This keeps the factory running efficiently.

Conclusion

Efficiency in food factories isn’t just about speed. It’s about staying clean, reliable, and cost-smart. Tailored flat homogeneous belts from Uyang Belting give food factories of all sizes a big advantage. With easy cleaning, custom designs, and worldwide support, they’re a wise choice for better productivity and safety.

Ready to improve your conveyor systems? Reach out to Uyang Belting for custom solutions that fit your factory.

FAQs

Q1: Are Uyang’s flat homogeneous belts certified for direct food contact?

Yes. All Uyang flat homogeneous belts meet FDA, EU 10/2011, and USDA food-grade standards, making them safe for meat, dairy, seafood, and bakery products.

Q2: How often do flat homogeneous belts need to be replaced?

Compared to standard PU belts, flat homogeneous belts last much longer. With good care, they can run for 2–3 years or more.

Q3: Can small food businesses afford tailored flat homogeneous belts?

Yes. Uyang Belting offers low minimum order quantities and flexible pricing, so both small and large factories can get custom belts.