Introduction

Walk into any modern food plant, and you’ll hear the hum of conveyors moving everything from raw chicken parts to neatly wrapped bakery goods. Conveyor belts are the silent backbone of the industry. Yet they also happen to be a hotspot for bacteria if not designed and maintained correctly. It only takes one unnoticed biofilm under a belt edge to set off a nightmare of recalls, inspections, and sleepless nights for quality managers.

That’s where the conversation about Positive Drive Belts comes in. Unlike traditional fabric belts that soak up moisture and create hidden pockets for bacteria, positive drive belts are built with a solid, homogeneous structure. For plants that want less scrubbing and more peace of mind, this design is changing the game.

So, what are the practical strategies to keep bacteria off conveyor belts in food processing? Let’s break it down into five key areas.

1. Choose Hygienic Materials and Belt Designs

Non-porous, homogeneous belt materials

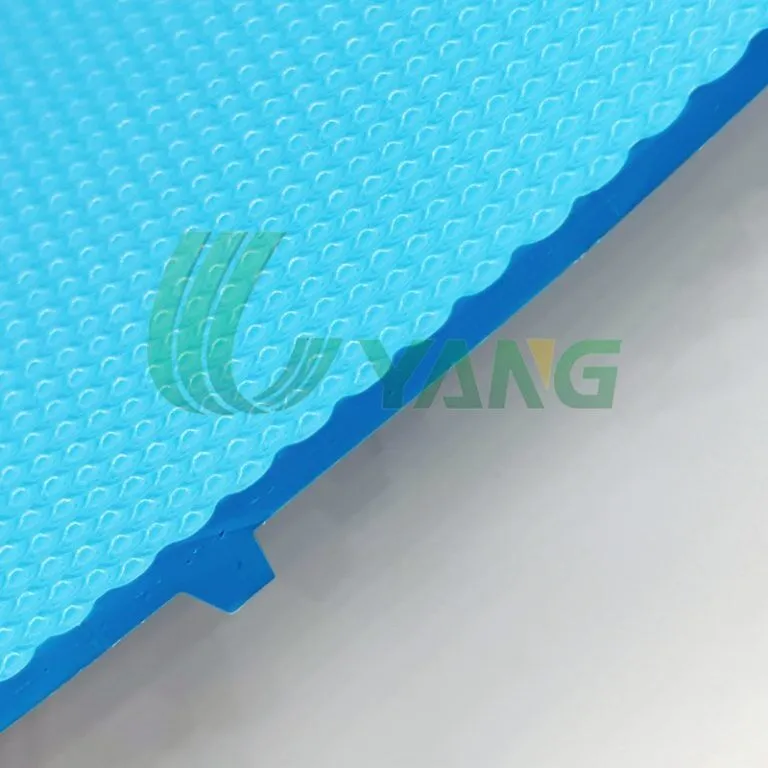

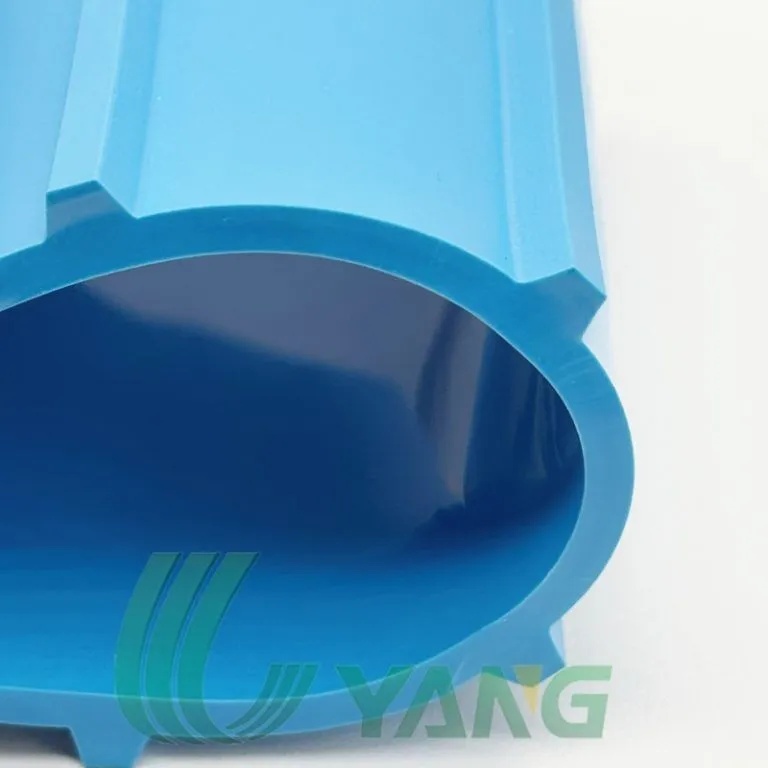

The first rule: don’t give bacteria a place to hide. Traditional PU or PVC belts often have fabric layers. Once moisture seeps in, it’s almost impossible to get rid of it completely. Positive drive belts produced by Uyang лент, are made from a single thermoplastic material (TPU). No seams, no fibers, no gaps.

I once visited a dairy plant in Germany that switched from layered PU belts to homogeneous ones. Their QA manager showed me a time log: cleaning that used to take 45 minutes per line now averaged 20. Less downtime, less labor, and noticeably fewer positive swab tests. It wasn’t rocket science—it was just the right belt design.

Open structures and minimized surfaces

It also helps when the belt design itself has fewer surfaces where residue can build up. Positive drive belts often come with simple, smooth profiles. When paired with open conveyor frames, cleaning crews can spray, scrub, and visually inspect without spending hours crouched under the line.

2. Incorporate Hygienic Design Components

Flat and open hinge concepts

Some belts use flat profiles with rounded edges that don’t trap food particles. In poultry plants, where fat and protein residues are everywhere, this is critical. One plant manager once joked that “chicken grease finds corners you didn’t even know existed.” Open hinge or flat positive drive belts make it easier for wash water to reach those spots.

Tool-free removal and modular parts

Another overlooked point is how fast the belt can be taken off for a deep clean. Systems like Saniclip, or custom quick-release mechanisms, let maintenance staff remove belts without special tools. Imagine a midnight shift where a line goes down. The faster you can remove and sanitize a belt, the quicker production is back online.

3. Utilize Automated Cleaning Systems

Clean-In-Place (CIP) integration

For high-throughput facilities—think frozen food factories running 24/7—manual cleaning alone isn’t enough. That’s where Clean-In-Place (CIP) comes into play. CIP sprays, foams, rinses, and sanitizes belts without disassembly. Positive drive belts, with their solid and non-absorbent surfaces, are particularly compatible with these systems.

One seafood processor in Southeast Asia reported that switching to easy-clean belts cut their nightly cleaning water use by 30%. That’s a lot of water saved, and in some regions, water cost is a very real pain point.

Engineered cleaning tools

Automated belt scrapers and brushes, positioned correctly, help remove sticky residues like starch or dairy film before they dry. Uyang Belting provides processing machines designed for fast and precise belt handling, which makes this kind of integration smoother.

4. Develop and Implement a Robust Sanitation Program

Documented cleaning schedules

Even the best belt won’t save a plant if there’s no consistent cleaning schedule. Bacteria thrive on inconsistency. Plants that perform documented, shift-by-shift cleaning routines reduce risks drastically. It’s not glamorous work, but having a logbook with dates, initials, and methods keeps everyone accountable.

Training and awareness

Here’s something often overlooked: staff training. A belt that’s FDA-approved and designed to perfection still fails if someone uses the wrong detergent or lets knives scratch the surface. Some plants run quarterly refresher courses where maintenance teams are shown the latest best practices. From our experience, the return on training hours is worth it—you avoid costly errors that happen when “everybody assumes they know.”

5. Optimize Hygiene with Materials and Process Efficiency

Durable, easy-to-clean materials reduce downtime

Positive drive belts last longer because they don’t delaminate or fray. Fewer replacements mean fewer interruptions. Imagine a bakery that has to stop mid-production because a belt is fraying and fibers could fall into dough. Switching to homogeneous belts practically eliminates that scenario.

Sustainable benefits

There’s also a sustainability angle. By reducing cleaning time and water usage, hygienic belts help plants cut operating costs and environmental impact. Some of our clients mention saving hundreds of liters of hot water per week. That’s money saved on energy too.

img.Sharp Nipple PU belt.webp

Conclusion

Keeping bacteria off conveyor belts in food plants isn’t about one magic trick. It’s about combining the right belt technology—like positive drive, homogeneous designs—with smart cleaning systems, disciplined sanitation programs, and staff who know what they’re doing.

At Uyang Belting, we’ve spent over 20 years engineering belts that don’t just move products but safeguard them. Whether you’re running a poultry plant in Brazil, a bakery in the US, or a seafood processor in Japan, the strategies remain the same: choose the right belt, make cleaning easy, and keep people trained.

Food safety isn’t negotiable. The question is whether your conveyor belts are helping—or quietly working against you.

FAQs

Q1: What is the main difference between a positive drive belt and a traditional PU/PVC belt?

A: A positive drive belt is made from a solid, homogeneous material with no fabric layers. Traditional PU/PVC belts often have fabric reinforcement, which can absorb moisture and harbor bacteria.

Q2: How often should conveyor belts in food plants be cleaned?

A: Most facilities clean belts after every shift, with weekly deep sanitation using steam or chemical wash. The exact frequency depends on the type of food being processed—raw meat lines require stricter protocols than bakery lines.

Q3: Are positive drive belts more expensive than traditional belts?

A: Yes, the upfront cost is usually higher. But the longer service life, reduced cleaning time, and lower contamination risks often make them cheaper in the long run. Many plants see ROI within the first year.