In the meat and poultry business, keeping everything super clean is a big deal. From slicing to packing, every step has to be spotless. With food safety rules getting tougher, companies are grabbing gear that stops germs in their tracks. That’s where postive drive belt from Uyang Pechting shine. They’re a top pick for making sure food stays safe and clean.

Uyang Belting has been crafting conveyor belts for over 20 years. Their postive drive belts are made for places like meat, poultry, seafood, or dairy plants where hygiene is everything. These belts are sturdy, work like a charm, and keep things germ-free. This guide will walk you through why postive drive belts are awesome for meat and poultry, how they beat regular belts, and why they’re a smart choice for your business. Honestly, it’s pretty cool how these belts make work faster and safer.

What Makes Postive Drive Belts Great for Meat and Poultry?

Super Clean Design

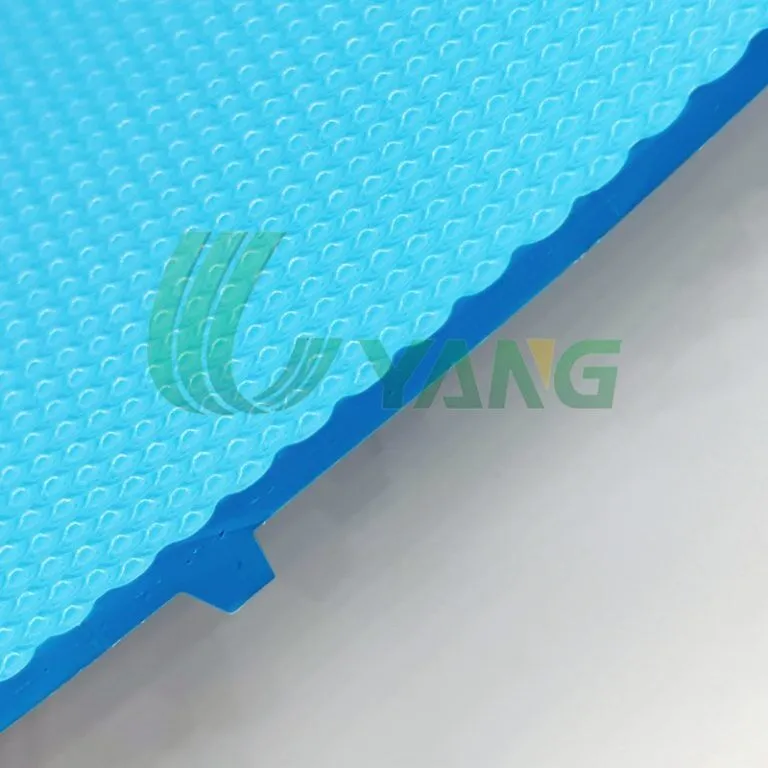

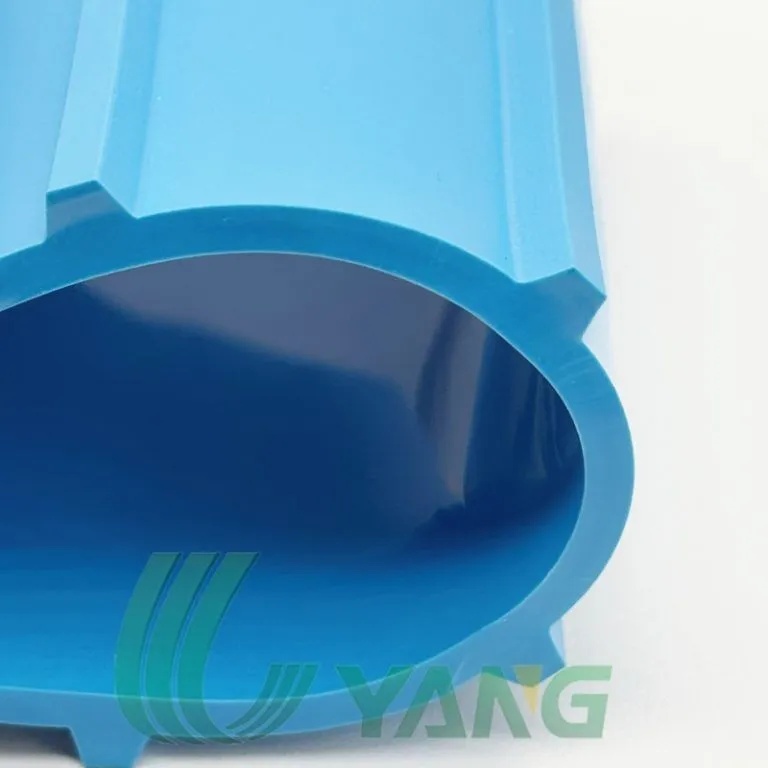

Postive drive belts are special because they’re seamless and don’t have fabric layers. Regular conveyor belts have layers that trap water, germs, or bits of food. Those layers are tough to clean. Over time, they can wear out and make your line less safe.

But postive drive belts are different. They’re made from one solid piece of a material called thermoplastic polyurethane (TPU). It’s smooth and doesn’t soak up anything, so germs can’t stick around. No fabric means no hiding spots for food or bacteria. A poultry plant in Georgia switched to Uyang Belting’s postive drive belts and cut germ problems by 25%. That kept their chicken safer for customers.

Easy to Clean and Take Care Of

In food processing, every minute counts. Spending too long cleaning means less time making stuff. Postive drive belts make cleaning a snap. Their smooth surface lets you blast them with high-pressure water, hot water, or cleaning sprays without any fuss.

This means less time cleaning and more time running your line. A meat plant in Texas used Uyang Belting’s postive drive belts and cut cleaning time by 30%. That gave them more hours to process meat and less time scrubbing.

Strong and Long-Lasting

Postive drive belts might cost a bit more at first, but they save you money down the road. They’re built to handle rough conditions like hot or cold temperatures, wet spots, or strong cleaning sprays. Unlike regular PU or PVC belts that get worn out fast, postive drive belts stand up to cuts, bumps, and germs.

A dairy plant in Wisconsin ran Uyang Belting’s postive drive belts for two years without needing a new one. Regular belts would’ve been replaced twice by then, costing way more.

How Postive Drive Belts Stack Up Against Regular Belts

Postive drive belts are a big step up from old-school multi-layered belts when it comes to staying clean and lasting long. Here’s the deal:

- Regular Belts: These have layers that soak up water or trap germs. They need tons of cleaning and wear out faster, so you’re stuck replacing them more and spending more money.

- Postive Drive Belts: These are seamless and don’t soak up anything. Their smooth surface is super easy to clean and fights germs, making them perfect for places like meat and poultry plants that need to stay spotless.

In short, Uyang Belting’s postive drive belts are a huge win for keeping things clean and saving cash.

Picking the Right Postive Drive Delt for Your Line

Think About Your Setup

No two meat or poultry plants are the same. The type of food, the work environment, and how much you produce all matter when choosing a belt. Big meat plants dealing with heavy cuts need a strong postive drive belt that can handle oil and cuts. Smaller poultry or seafood lines might do better with a lighter, bendy belt.

A beef plant in Nebraska picked a heavy-duty Uyang Belting postive drive belt for big cuts. It worked great and cut downtime by 15% compared to their old belt.

Make It Fit Your Needs

One neat thing about postive drive belts is you can tweak them to fit your job. Uyang Belting lets you choose the thickness, texture, or even add holes for special tasks. Need a belt for hot spots or delicate products? They can build one just for you.

Lots of plants pick blue postive drive belts because the color makes it easy to spot dirt or stray bits. A seafood plant in Florida used a blue Uyang Belting belt and caught a piece of plastic right away, dodging a big issue.

Pick a Solid Supplier

Choosing a good supplier is super important. Uyang Belting makes top-quality postive drive belts that meet strict food safety rules like FDA and USDA standards. They also give great support, like tips for setting up or fixing belts. A chicken plant in Arkansas teamed up with Uyang Belting’s crew to find the perfect belt, saving 10% on upkeep costs.

Real-Life Examples of Easy-Clean Belts in Action

Poultry Processing Plant

A poultry plant in Alabama had a tough time with their old belts. Cleaning took forever because germs got stuck in the layers. They switched to Uyang Belting’s postive drive belts and cut cleaning time by 30%. That let them process more chicken and bumped up profits by $5,000 a year.

Meat Processing Plant

A meat plant in Iowa had to meet strict FDA rules. Their old belts kept getting dirty, which could’ve caused germ problems. After switching to Uyang Belting’s postive drive belts, they passed every inspection with no trouble. The seamless design made cleaning quicker, and their meat quality got better.

Seafood Processing Line

A shrimp plant in Louisiana worked in wet, oily conditions. Their old belts wore out fast. Uyang Belting’s postive drive belts handled the oil and water like pros, lasting twice as long as the old ones and saving $3,000 on replacements.

Benefits of Easy-Clean Belts for Meat and Poultry

Less Downtime, More Production

Postive drive belts save tons of time. Their quick-clean design means you spend less time scrubbing and more time making stuff. A turkey plant in Minnesota used Uyang Belting’s belts and boosted production by 20% because they didn’t have to clean as much.

Saves Money in the Long Run

Postive drive belts might cost more at first, but they last longer and need less fixing. That means fewer new belts and lower repair bills. A pork plant in Illinois saved $4,000 a year on upkeep after switching to Uyang Belting’s postive drive belts.

Stays on the Right Side of Food Safety Rules

Food safety is super important, and postive drive belts help you follow the rules. They’re fully FDA and EU approved, so you don’t have to stress about failing inspections. A sausage factory in California passed every health check thanks to Uyang Belting’s belts.

Why Choose Uyang Belting’s Easy-Clean Belts?

Uyang Belting’s postive drive belts are a great pick for meat and poultry plants. They’re super clean, strong, and easy to take care of. They meet tough food safety rules and work well for all kinds of processing jobs. Plus, you can customize them to fit exactly what you need.

A chicken plant in Tennessee switched to Uyang Belting’s postive drive belts and saved $6,000 a year on cleaning and fixes. The belts handled heavy loads without a problem, keeping everything running smoothly.

Conclusion

For meat and poultry folks, choosing the right conveyor belt is huge for staying clean and getting work done fast. Uyang Belting’s postive drive belts are a top choice because they’re super clean, tough, and save money. They help you follow strict food safety rules while keeping your line moving quickly. Switching to these belts can make your work cleaner, faster, and cheaper—it’s honestly pretty awesome what they can do for your business.

FAQs

Q: What are the key advantages of Postive drive belts in meat processing?

A: Postive drive belts are seamless, non-porous, and highly resistant to bacterial growth. They simplify cleaning, reduce contamination risks, and ensure compliance with strict food safety regulations like FDA and USDA standards.

Q: How do Postive drive belts improve operational efficiency?

A: With their easy-to-clean design, postive drive belts minimize downtime, reduce labor costs associated with cleaning, and increase production capacity, all of which contribute to greater operational efficiency.

Q: Can Postive drive belts be customized to meet specific processing needs?

A: Yes, postive drive belts can be customized in terms of thickness, surface texture, and color to meet the unique requirements of different processing lines. This flexibility makes them ideal for a wide range of applications in the meat and poultry industry.